A coiled tubing experimental system and method

An experimental method and oil tubing technology, applied in earthwork drilling, teaching models, measurement, etc., can solve problems that restrict the development of coiled tubing, and achieve the effect of improving operation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

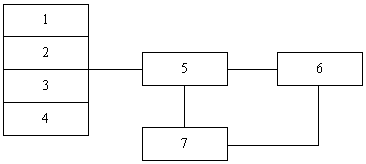

[0031] The purpose of the present invention is to solve the problems of full-scale testing of coiled tubing technology and tool performance, related scientific experimental research and training of coiled tubing technicians. The present invention provides such figure 1 The shown coiled tubing experiment system can carry out the research on the cutting-edge technology of coiled tubing, the testing and evaluation of coiled tubing supporting tools, the full-scale tool simulation experiment and the training of coiled tubing process technicians. This system solves the problem of domestic coiled tubing technology and tools for full-scale testing, and provides technical support for the development of coiled tubing operation technology.

[0032] The invention relates to an experimental system for full-scale testing of coiled tubing technology and tools. It can be used to guide downhole operations such as on-site coiled tubing drilling, grinding, fishing, cutting, and drilling, as well as ...

Embodiment 2

[0046] Based on Example 1, in this implementation, the power system 1 includes an electric motor, an electric control cabinet, and an air compressor. The electric motor is respectively connected to the electric control cabinet and the air compressor, and the air compressor is connected to the coiled tubing system 5. The drum connection.

[0047] The control system 2 is composed of an electrical control system and a hydraulic control system. The electrical control system is composed of a 90kw motor, a 45kw motor and an air pump. The two motors provide power to the air pump and drive the air pump to the drum in the tubing system 5. The coiled tubing lubrication; the hydraulic control system consists of a hydraulic pump, a hydraulic oil tank, a radiator, a filter, an accumulator, related hydraulic components and related accessories, and a hydraulic control circuit composed of this. The power of the 180 pump of the hydraulic control system is driven by a large motor, and the 45 pump ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com