Pull-out test device of glass fiber rib anti-floating anchor and test method of pull-out test device

A technology of glass fiber reinforcement and anti-floating anchor, which is applied in the direction of applying stable tension/pressure to test the strength of the material, which can solve the problems affecting the strength of the anchor body, the material of the rod body is easy to corrode, and the anchoring effect is damaged, and the test data can be achieved. Accurate and reliable, shortened test time, scientific and reasonable measurement method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

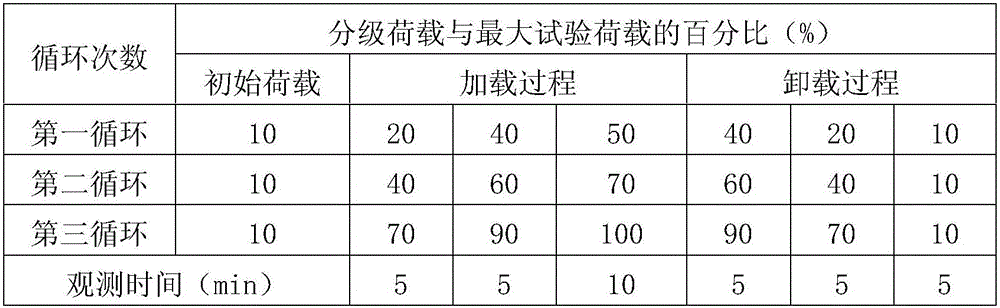

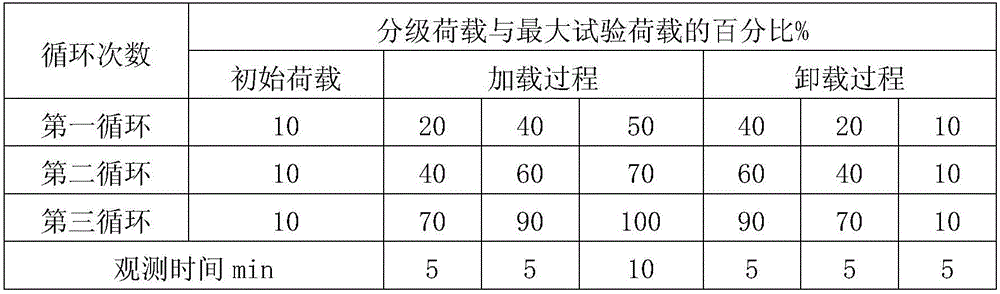

[0029] Example: The diameter of the medium glass fiber reinforced anti-floating anchor rod is 25mm, the anchorage depth is 12.000m, the maximum loading pressure is 20t, and the multi-cycle loading method is adopted. The specific loading form is shown in the table below. Under the initial load, the reference value of the anchor head displacement should be measured and read 3 times, and when the degrees at intervals of 5 minutes are the same, it can be used as the reference value of the anchor head displacement. After each loading and unloading is stable, the anchor head displacement should be measured and read no less than 3 times within the observation time.

[0030] In addition, according to the above-mentioned embodiment, the present invention provides a test method for detecting the relationship between the deformation and the load of the bolt using the above-mentioned device, which includes the following steps:

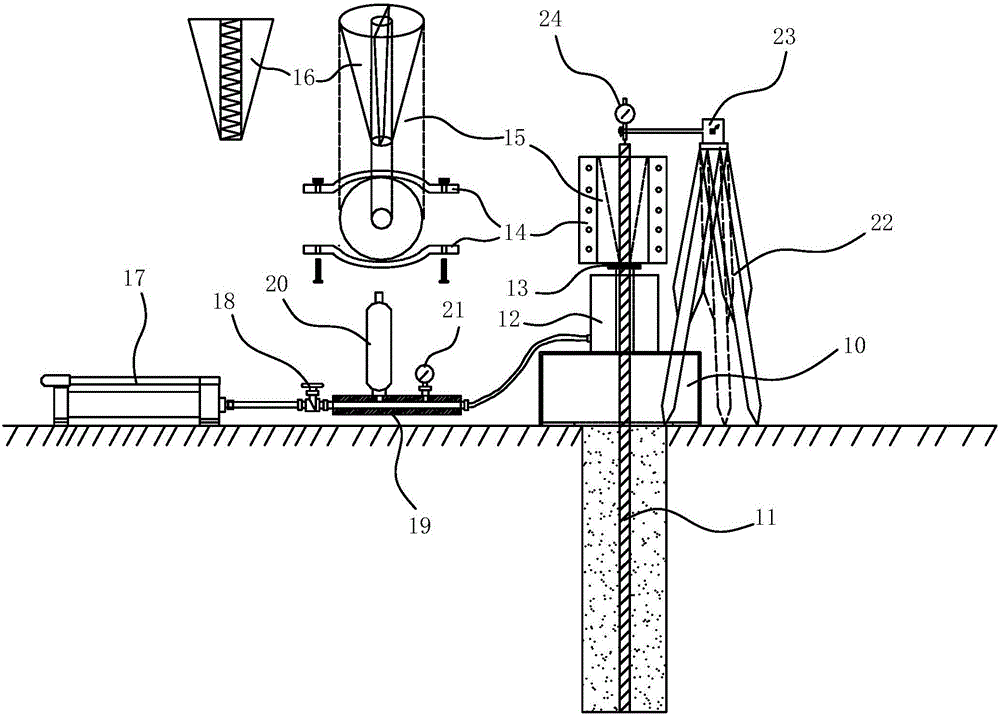

[0031] S1. Equipment installation: place the base 10 on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com