Flexible fine copper wire shielding drag chain power cable

A copper wire shielding, power cable technology, applied in power cables with shielding/conducting layers, insulated cables, bendable cables, etc., can solve the problems of short use time and easy failure of drag chain cables, and achieve excellent The effect of high mechanical properties, high temperature resistance and excellent performance indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

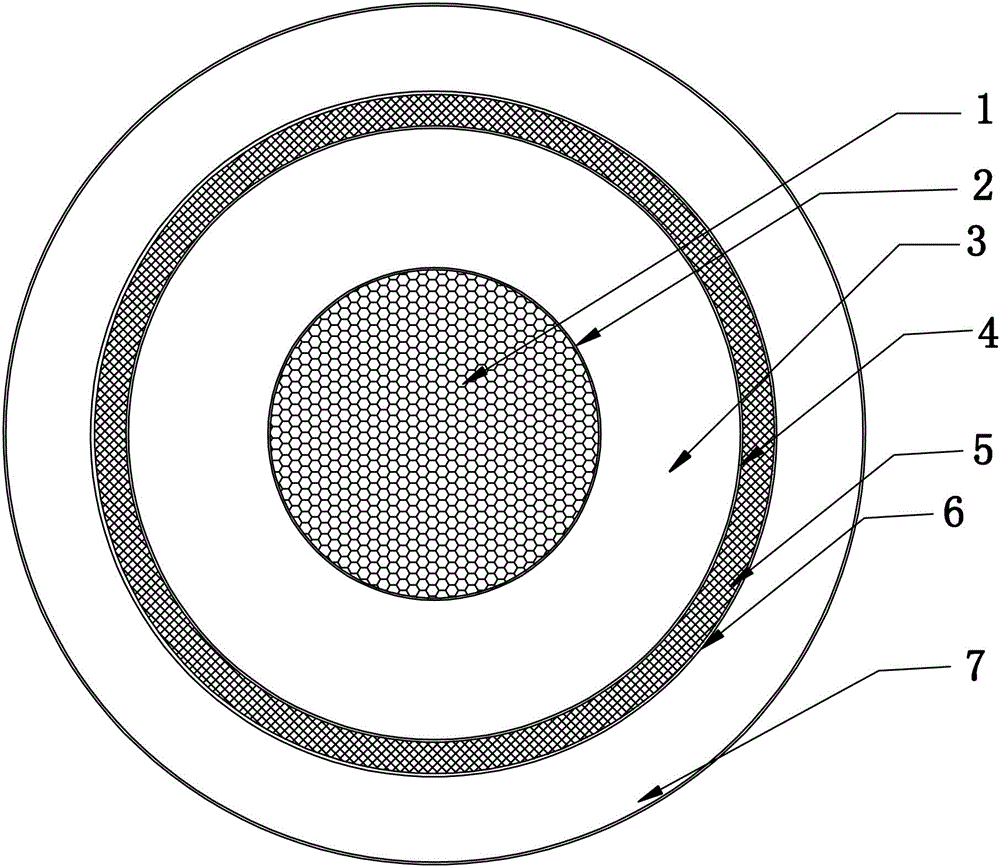

[0031] Such as figure 1 As shown, a kind of flexible thin soft copper wire shielded drag chain power cable, the cable is successively composed of conductor layer 1, first isolation layer 2, insulation layer 3, second isolation layer 4, shielding layer 5, third isolation layer from inside to outside Layer 6 and outer sheath layer 7, characterized in that:

[0032] Conductor layer 1 is a conductor layer made of stranded conductors of category 6 extra-soft structure in IEC60228, and the bundle pitch diameter ratio is 22 to 20;

[0033] The first isolation layer 2 is a layer of polyester tape overlapping and wrapping outside the conductor layer 1;

[0034] The insulating layer 3 is an ethylene-propylene rubber insulating layer;

[0035] The second isolation layer 4 is two layers of polyester tapes overlapped and wrapped outside the insulating layer 3;

[0036] The shielding layer 5 is a braided copper wire shielding layer;

[0037] The third isolation layer 6 is two layers of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| Overlap degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com