High Frequency Transformer Winding Frame

A high-frequency transformer and winding frame technology, which is applied in the direction of inductance/transformer/magnet manufacturing, coil manufacturing, electrical components, etc., can solve the problems of copper coil winding and unusability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

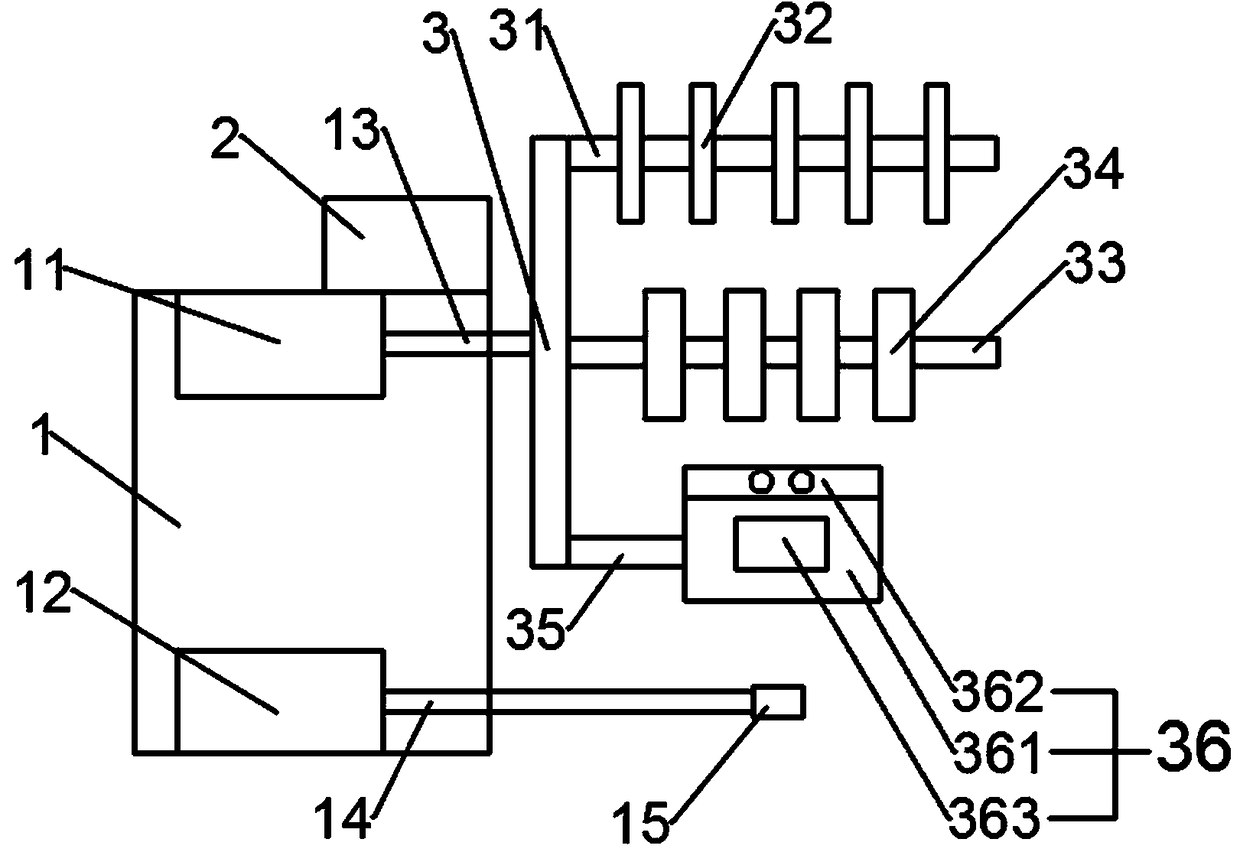

[0023] figure 1 The high-frequency transformer bobbin shown includes a box body 1, a control system 2, a bracket 3, a first motor 11 and a second motor 12, and the control system 2 connects the first motor 11 and the second motor 12 through wires. The motor 11 and the second motor 12 are installed in the box 1 body. The first motor 11 is a straight step motor, and the second motor 12 is a step motor. The straight stepping motor can push the bracket to move laterally, and can process the magnetic core with the rotation of the stepping motor. The straight stepping motor is fixed on the top in the casing 1 by bolts, and the stepping motor is fixed on the bottom in the casing 1 by bolts. The bolts fix the linear motor and the stepper motor, which can prevent the vibration during work from affecting the processing of the high-frequency transformer.

[0024] One side of the box body 1 is the winding side, and two through holes are arranged on the winding side, corresponding to th...

Embodiment 2

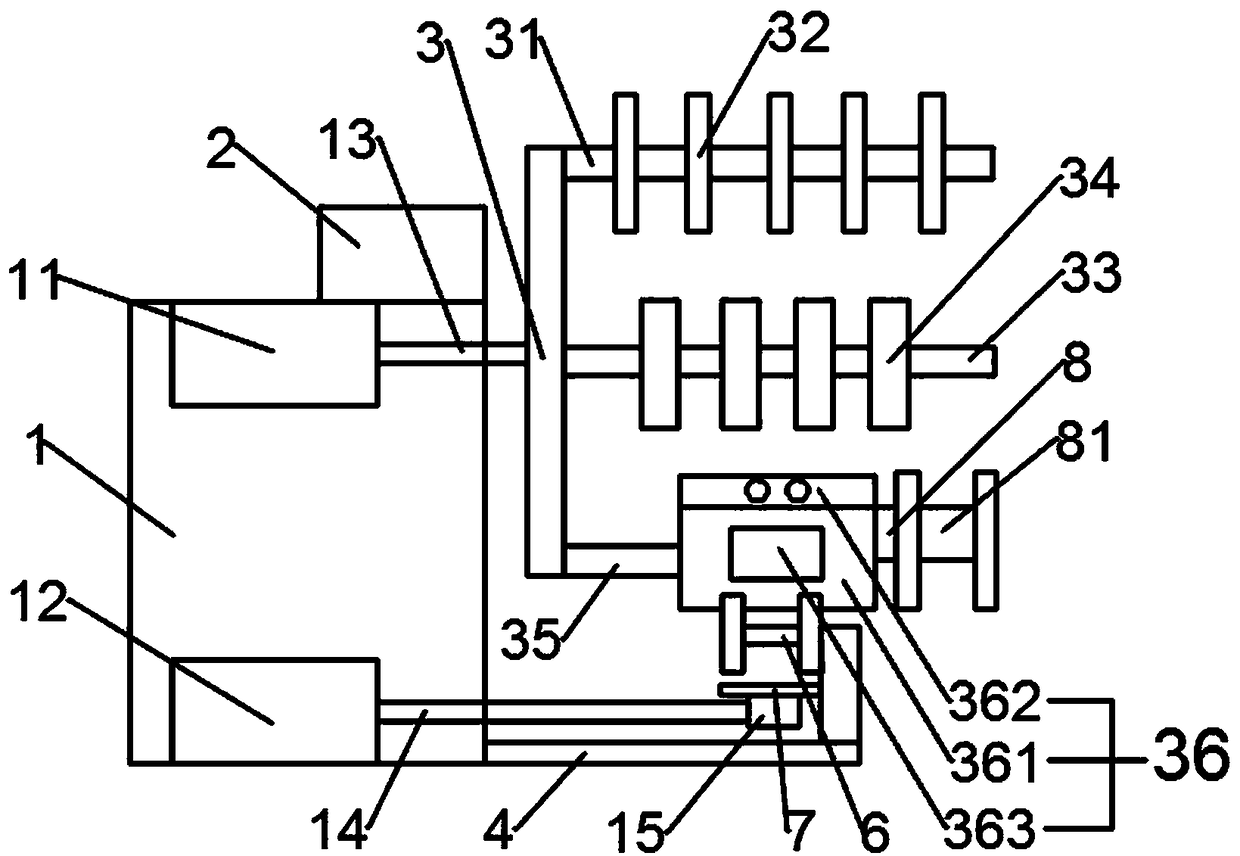

[0028] figure 2 The bottom of the winding side as shown is fixed with a base 4, a vertical plate 5 is fixed on the base 4, a cross bar 6 is arranged on the top of the vertical plate 5, two spacers 32 are arranged on the cross bar 6, and the vertical plate 5 There are two pipe columns 7 fixed in the middle, which is to prevent the insulation tape from falling off and sticking to dust and foreign matter when it is not in use, which will affect the processing of the high-frequency transformer. The insulating tape can be placed on the cross bar 6, and the insulating tape passes through the pipe column 7, which is convenient for the operator to use the insulating tape to process the high-frequency transformer.

[0029] The hub 36 is fixedly connected with the wire management holder 8 , and the wire management holder 8 includes a round tube 81 and spacers 32 arranged at both ends of the round tube 81 . The wire management reel is directly installed between the spacers 32 of the wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com