Optimum Design Method of AC Motor Branch Asymmetric Winding Arrangement and Branch Asymmetric Winding Arrangement Scheme

An AC motor, optimized design technology, applied to electric components, manufacturing motor generators, shape/style/structure of winding conductors, etc., can solve the problems of reduced motor efficiency and stability, irregularity, and increased winding loss, etc., to achieve Improve design accuracy and efficiency, improve efficiency and stability, and reduce the effect of circulation between branches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The specific embodiments of the present invention are described below so that those skilled in the art can understand the present invention, but it should be clear that the present invention is not limited to the scope of the specific embodiments. For those of ordinary skill in the art, as long as various changes Within the spirit and scope of the present invention defined and determined by the appended claims, these changes are obvious, and all inventions and creations using the concept of the present invention are included in the protection list.

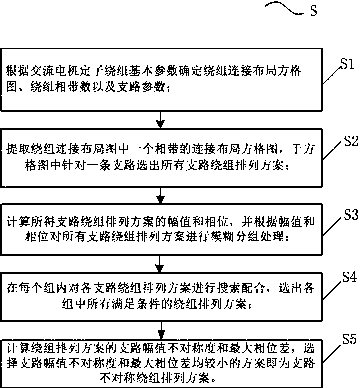

[0053] According to an embodiment of the present application, see figure 1 , figure 1 It is a flow chart of the method for optimizing the arrangement of asymmetrical windings of AC motor branches in the present invention; the method includes steps S1 to S5, specifically:

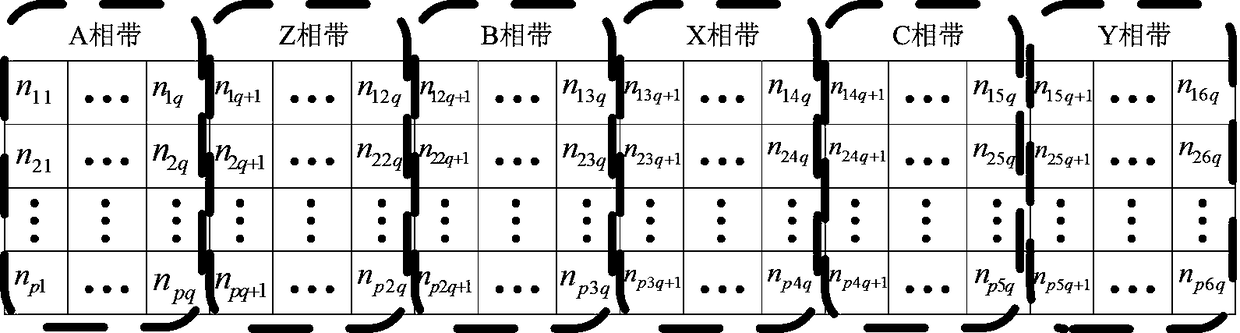

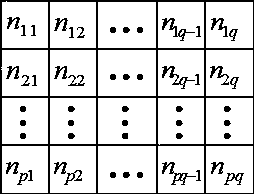

[0054] In step S1, according to the basic parameters of the stator winding of the AC motor, the winding layout grid diagram, the number of winding phase...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com