Application of polyacrylamide and hydroxypropyl methyl cellulose composition to pesticide preparation

A technology of hydroxypropyl methylcellulose and polyacrylamide, which is applied in the field of pesticides to achieve the effects of improving effective utilization, accelerating sedimentation, and increasing density difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

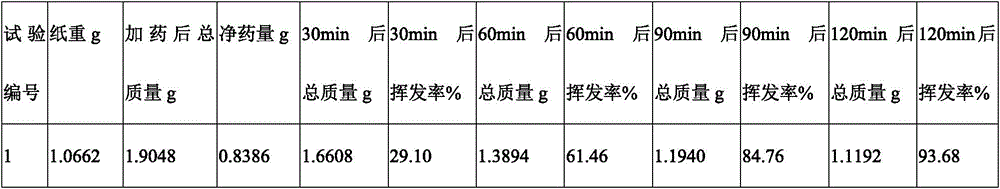

Examples

Embodiment 1

[0022] Embodiment one: Taking 5% abamectin water emulsion (EW) as an example, abamectin is a semi-synthetic sixteen-membered macrocyclic lactone compound, due to the anionic hydroxyl-OH and carboxyl-COOH present in the functional group structure and carbonyl C=O, choose cationic polyacrylamide-based aqueous solution and abamectin aqueous emulsion aqueous solution for mixing. Add the materials in the ratio of cationic polyacrylamide:anionic polyacrylamide:hydroxypropyl methylcellulose=5:2:3 to 100mL deionized water at 25°C in sequence, and fully stir to dissolve. Among them, cationic polyacrylamide has a molecular weight of 8 million to 20 million and has a linear structure; the methoxyl content of hydroxypropyl methylcellulose is between 25% and 32%, and the hydroxypropyl content is between 10% and 15%. Between %, add cationic polyacrylamide, anionic polyacrylamide, and hydroxypropyl methylcellulose in sequence. After adding cationic polyacrylamide, keep warm at 25°C and fully...

Embodiment 2

[0023] Example 2: Preparation of a disintegrant containing polyacrylamide and hydroxypropylmethylcellulose. During the processing process, the polyacrylamide and hydroxypropyl methylcellulose in the formula ratio must be fully melted according to the method in Example 1 to form a gel-state aqueous solution and then evenly spray on fillers: white carbon black, diatomaceous earth, Fully adsorbed in calcined kaolin, light calcium carbonate, etc. The formed disintegrant can be applied to dosage forms such as wettable powder and emulsifiable concentrate.

[0024] The above examples of implementation and the solvents and methods used are limited to this test, but the agricultural preparations prepared according to the combination required in this patent are not limited to these solvents, and there may also be differences, all of which are described in this patent. within the scope of authority. For example, in the UAV atomized spray of 48% chlorpyrifos ultra-low volume (ULV), it i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com