Herbicidal composition and applications thereof

A herbicidal composition and the technology of the composition, applied in the direction of application, herbicide, algicide, biocide, etc., can solve the problems of limited use, low control activity of broad-leaved weeds, etc., and achieve economical use cost and less use of drugs Quantity, high safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

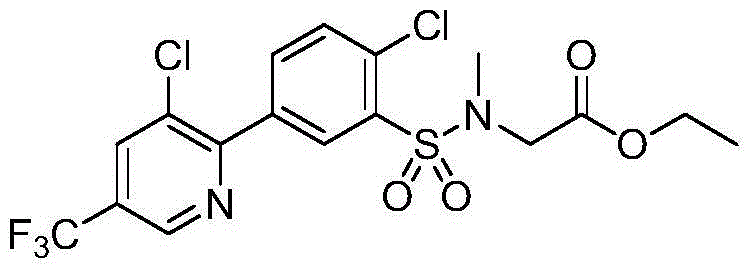

Image

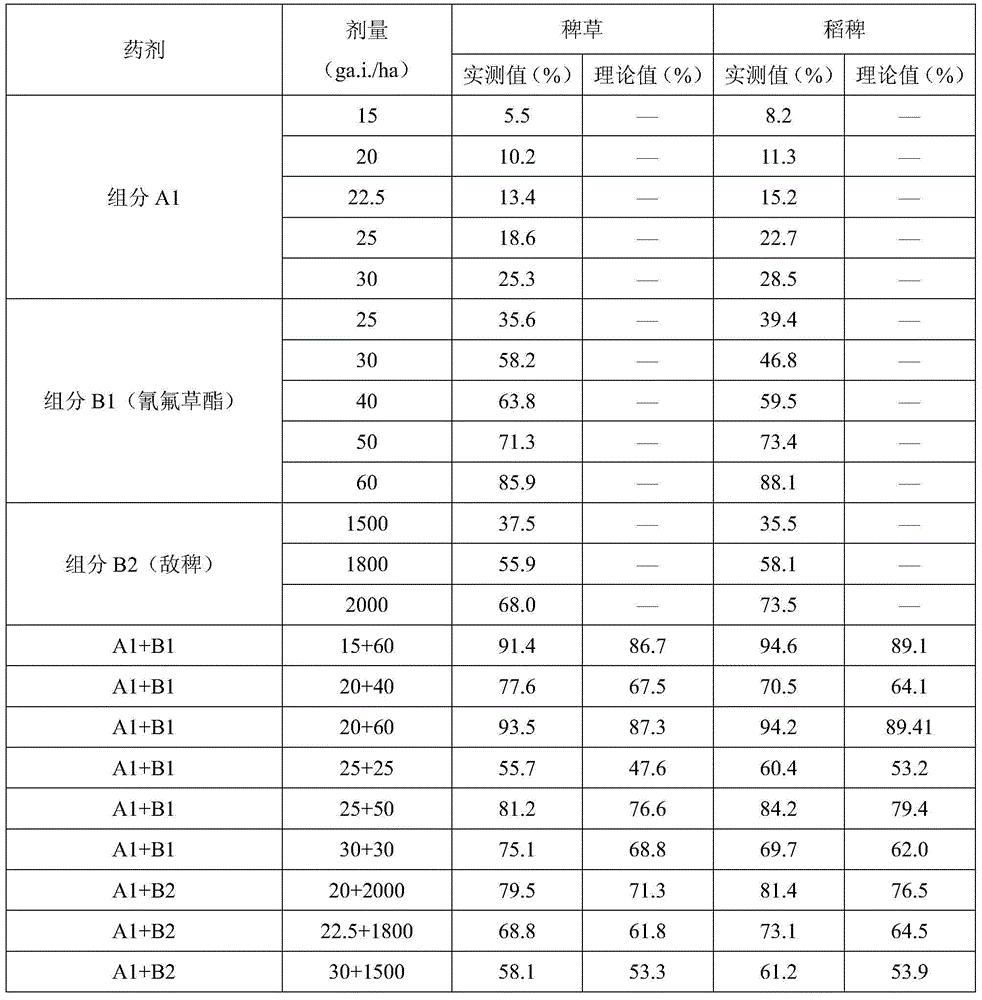

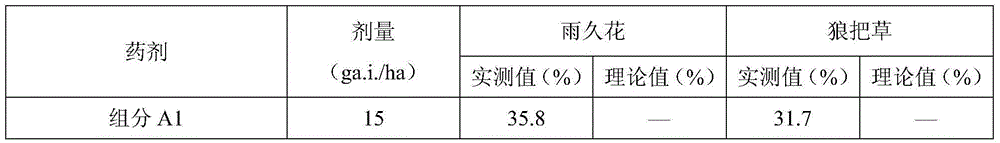

Examples

Embodiment 140

[0054] Example 140%% Compound A1 Cyhalofop-methyl (8:32) suspension concentrate

[0055] According to the formula requirements, 8 parts of compound A1, 32 parts of cyhalofop-ester, 4 parts of Nongru 0201B, 4 parts of sodium salt of alkylnaphthalene sulfonic acid condensation polymer, 2 parts of dispersant SP-2728, 2 parts of Nongru 1601# , 0.2 parts of xanthan gum, 0.5 parts of white carbon black, 5 parts of ethylene glycol, make up to 100% with water, add them to the mixing tank in turn and mix them, first go through high shear for coarse crushing and homogenization, and then pump them into the sand Carry out fine grinding in the mill, and use a particle size distribution instrument to detect the particle size of the sand-milled material. When the particle size reaches the standard requirement, filter to obtain 40%% compound A1·cyhalofop-ethyl suspension concentrate.

Embodiment 240

[0056] Example 240% Compound A1 Cyhalofop-methyl (10:30) suspension concentrate

[0057] According to the formula requirements, 10 parts of compound A1, 30 parts of cyhalofop-ester, 4 parts of sodium methylnaphthalenesulfonate formaldehyde condensate, 4 parts of Nongru 0201B, 4 parts of sodium salt of alkylnaphthalenesulfonic acid condensation polymer, 2 parts Nongru 1601#, 0.2 parts of xanthan gum, 0.5 parts of white carbon black, 5 parts of ethylene glycol, make up to 100% with water, add to the mixing tank in turn and mix, first go through high shear for coarse crushing and homogenization, and then Pump it into a sand mill for fine grinding, and use a particle size distribution meter to detect the particle size of the sand-milled material. When the particle size reaches the standard requirement, filter it to obtain 40% compound A1·cyhalofop-ethyl suspension concentrate.

Embodiment 330

[0058] Example 330% Compound A1 Cyhalofop-methyl (10:20) Suspension Concentrate

[0059] According to the formula requirements, mix 10 parts of compound A1, 20 parts of cyhalofop-ethyl, 5 parts of dispersant SP-28F, 3 parts of wetting agent SP-SC3266, 4 parts of Nongru 0201B, 2 parts of Nongru 1601#, 0.1 part of yellow Raw rubber, 0.5 parts of white carbon black, 5 parts of ethylene glycol, and water to make up to 100%, are added to the mixing tank in turn for mixing, first undergo high shear for coarse crushing and homogenization, and then pumped into the sand mill for Finely grind, and use a particle size distribution instrument to detect the particle size of the sand-milled material. When the particle size reaches the standard requirement, filter to obtain a 30% compound A1·cyhalofop-ethyl (10:20) suspension concentrate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com