Potato drink and making method thereof

A production method and beverage technology, which are applied in the directions of food ingredients as taste improvers, food ingredients as taste improvers, food science, etc. Simple, good health function, long-lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

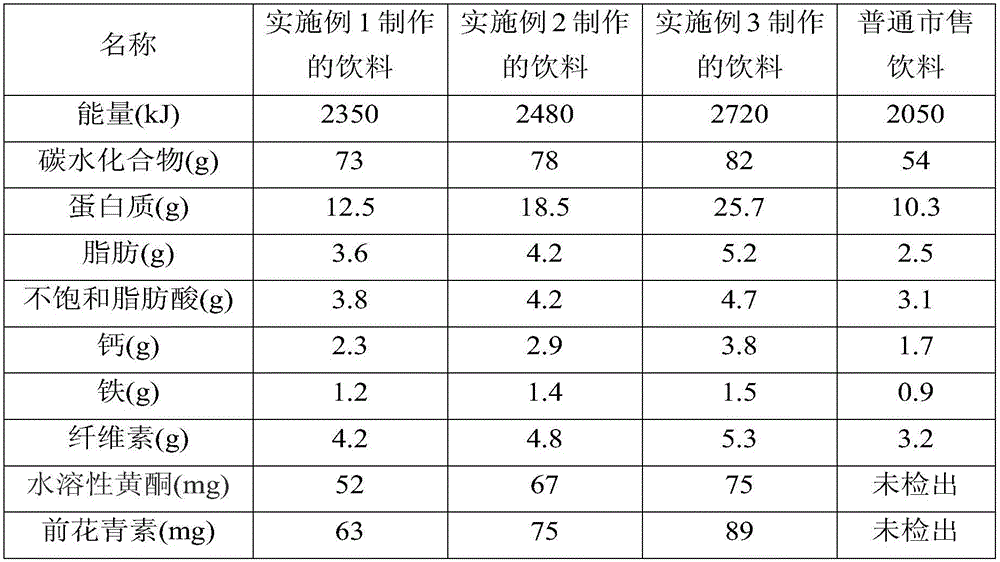

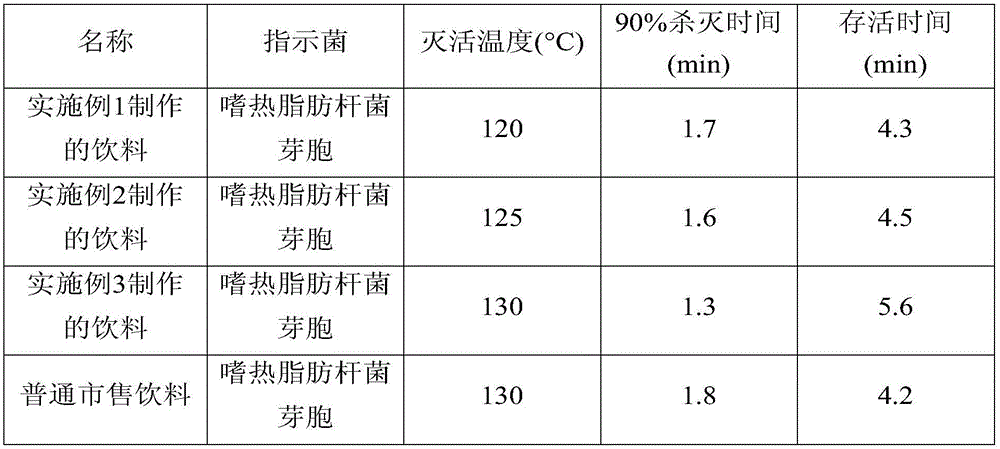

Examples

Embodiment 1

[0033] A kind of preparation method of potato drink

[0034] Include the following steps:

[0035] Step a, beating: mash the potato dregs 4 hours after the potato starch was extracted, add pure water 10 times the weight of the potato dregs, and stir for 30 minutes while boiling to obtain concentrated potato pulp;

[0036] Step b, passing through a colloid mill: put the concentrated potato pulp obtained in step a into a single-cycle colloid mill for grinding for 1 hour until the emulsification fineness of the potato pulp is 2 μm;

[0037] Step c, enzyme treatment: add 0.2% α-liquefied amylase by weight of potato dregs to the potato pulp treated in step b, adjust the pH of the potato pulp to 6.0 at a temperature of 60°C, and perform enzyme treatment for 3 hours;

[0038] Step d, enzyme inactivation: heat and boil the solution after the enzyme treatment in step d for 30 minutes, and perform enzyme inactivation treatment;

[0039] Step e, deployment: add additives to each kilogr...

Embodiment 2

[0045] A kind of preparation method of potato drink

[0046] Include the following steps:

[0047] Step a, beating: mash the potato dregs 2 hours after the potato starch was extracted, add pure water 20 times the weight of the potato dregs, and stir for 40 minutes while boiling to obtain concentrated potato pulp;

[0048] Step b, passing through a colloid mill: put the concentrated potato pulp obtained in step a into a single-cycle colloid mill for grinding for 3 hours until the emulsified fineness of the potato pulp is 50 μm;

[0049] Step c, enzyme treatment: add 1.0% glucoamylase by weight of potato dregs to the potato pulp treated in step b, adjust the pH of the potato pulp to 7.0 at a temperature of 70°C, and perform enzyme treatment for 4 hours;

[0050] Step d, enzyme inactivation: heat and boil the solution after the enzyme treatment in step d for 60 minutes, and perform enzyme inactivation treatment;

[0051]Step e, deployment: add additives to the solution after en...

Embodiment 3

[0057] A kind of preparation method of potato drink

[0058] Include the following steps:

[0059] Step a, beating: mash the potato dregs 2 hours after the potato starch was extracted, add pure water 15 times the weight of the potato dregs, and stir for 35 minutes while boiling to obtain concentrated potato pulp;

[0060] Step b, passing through a colloid mill: put the concentrated potato pulp obtained in step a into a single-cycle colloid mill for grinding for 2 hours until the emulsified fineness of the potato pulp is 26 μm;

[0061] Step c, enzyme treatment: add 0.6% α-liquefied amylase by weight of potato dregs to the potato pulp treated in step b, adjust the pH of the potato pulp to 6.5 at a temperature of 65°C, and perform enzyme treatment for 3.5 hours;

[0062] Step d, enzyme inactivation: heat and boil the solution after the enzyme treatment in step d for 45 minutes, and perform enzyme inactivation treatment;

[0063] Step e, deployment: add additives to each kilogr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com