A method and device for preparing solid adsorbent by thermocatalysis of high-concentration nonylphenol polyoxyethylene ether wastewater

A technology of nonylphenol polyoxyethylene ether and thermal catalysis, which is applied in chemical instruments and methods, adsorption water/sewage treatment, water pollutants, etc., can solve the problems of difficult normal growth and metabolism of anaerobic bacteria, limited efficiency of microbial electricity generation, Anaerobic methanogenesis technology has limited effects and other problems, and achieves the effects of large environmental and economic benefits, easy engineering, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

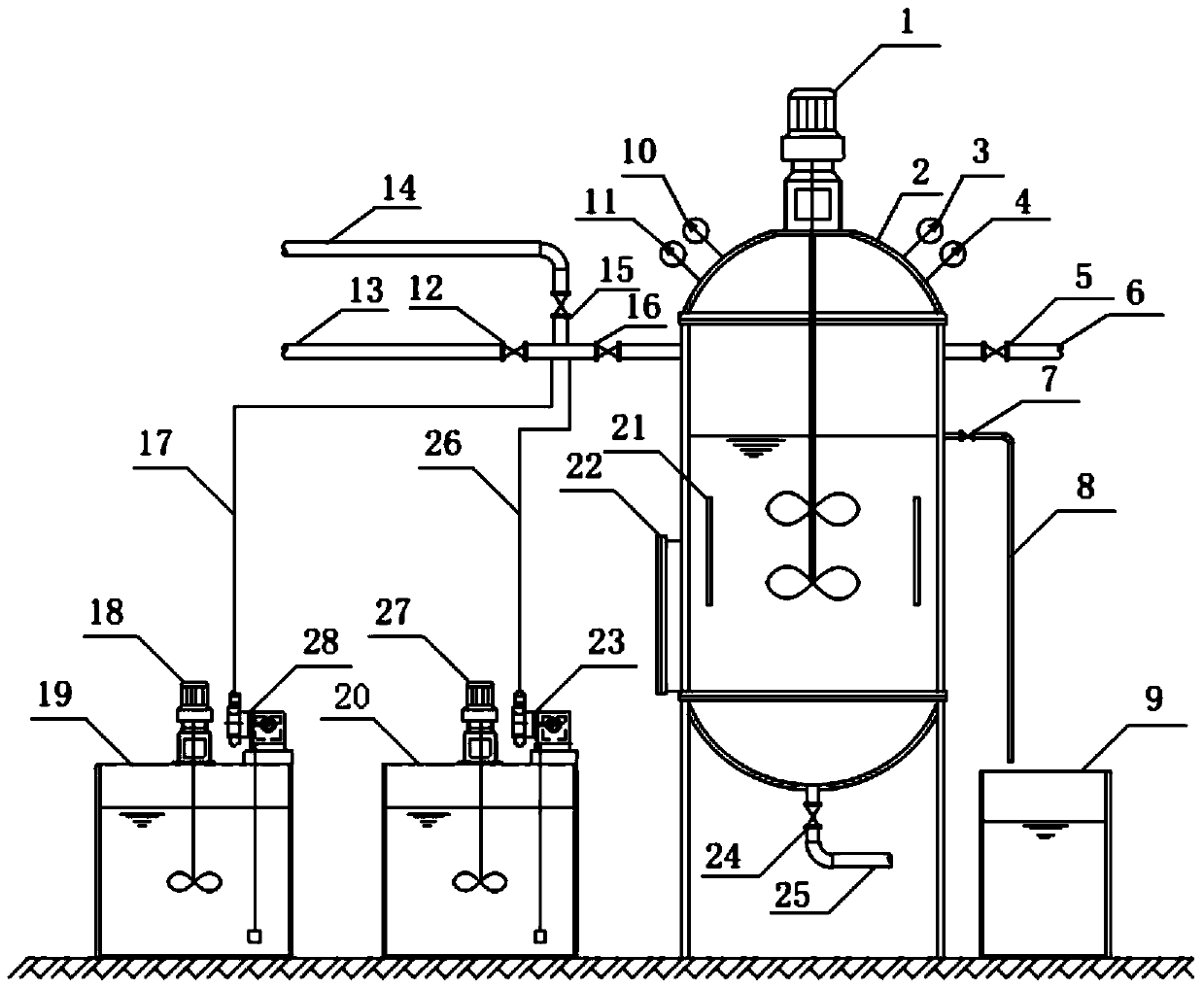

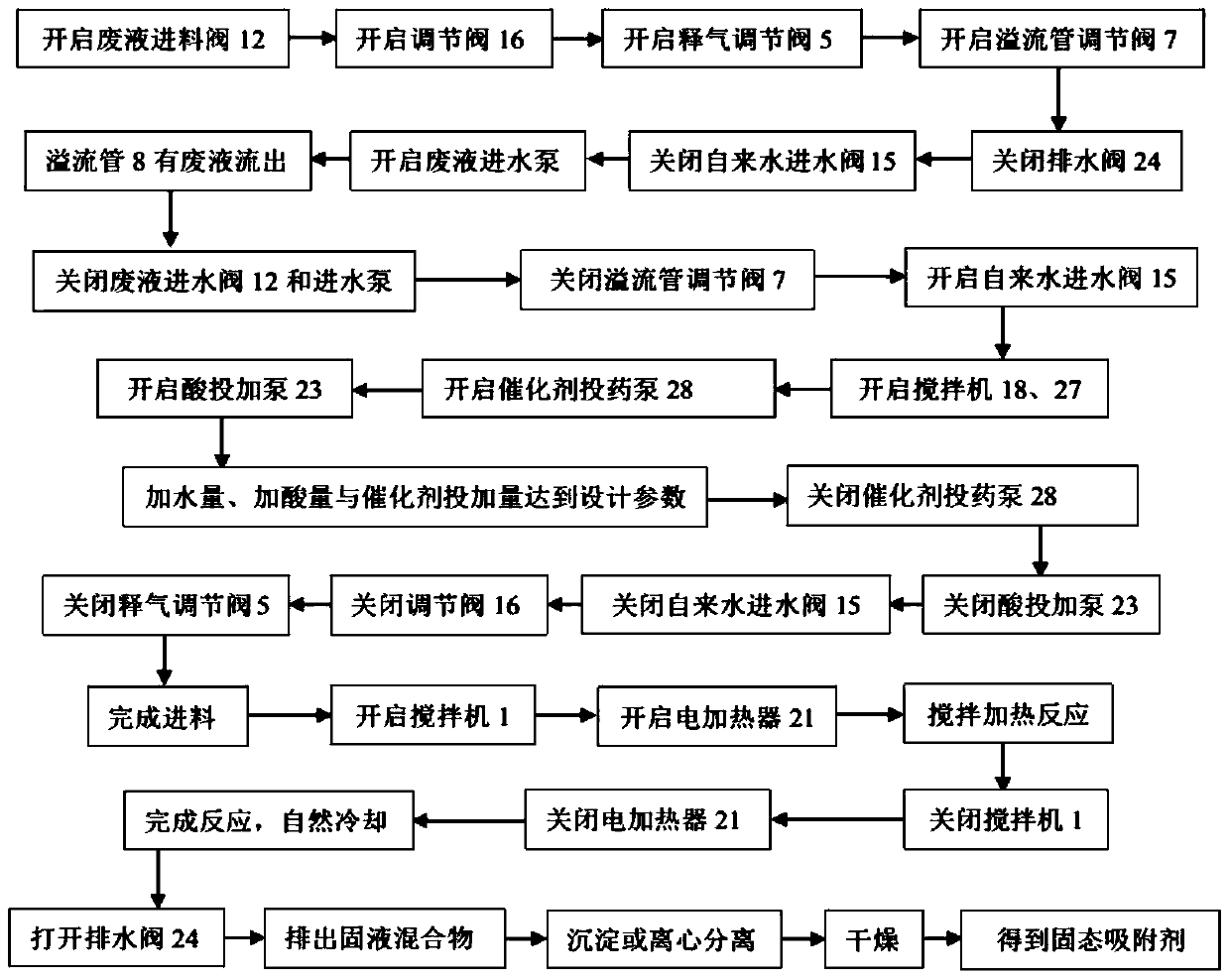

Method used

Image

Examples

Embodiment 1

[0035]The high-concentration nonylphenol polyoxyethylene ether wastewater in this example is taken from the production process of a certain fluoropolymer company. Unable to obtain significant treatment effect. The thermocatalytic technology proposed in this embodiment is used to treat this kind of high-concentration raffinate. The specific methods and steps are: (1) injecting high-concentration nonylphenol polyoxyethylene ether wastewater into the thermocatalytic reactor; (2) injecting Catalyst hematite powder and 98% concentrated sulfuric acid are injected in the reactor according to the dosage of 1.5g / (L waste liquid), 0.1g / (L waste liquid) respectively, and airtight reactor; (3) reactor is heated to 190°C, stirring and reacting for 3.0h; (4) After cooling, discharge the residue in the reactor and carry out solid-liquid separation, and the obtained black powdery solid substance will be a solid adsorbent after drying, which can be used for other low-cost Concentrated wastewa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com