A method and device for preparing solid derived fuel by degassing-catalytic carbonization of high-concentration industrial organic waste liquid

A technology of organic waste liquid and derived fuel, which is applied in the fields of biofuel, waste fuel, chemical instruments and methods, etc., can solve the problems such as the inability to realize engineering application, the difficulty of normal growth and metabolism of anaerobic bacteria, and the limited effect of anaerobic methane production technology. , to achieve the effect of harmless and resource utilization, environment and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

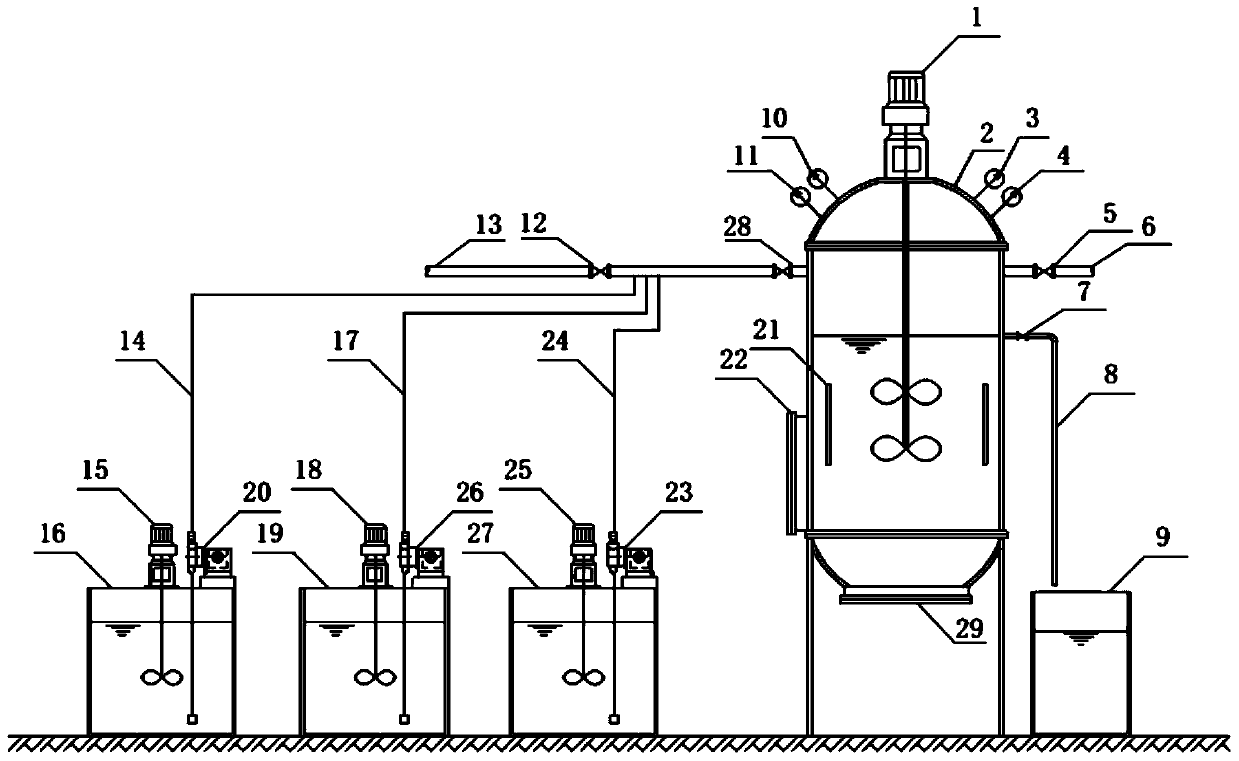

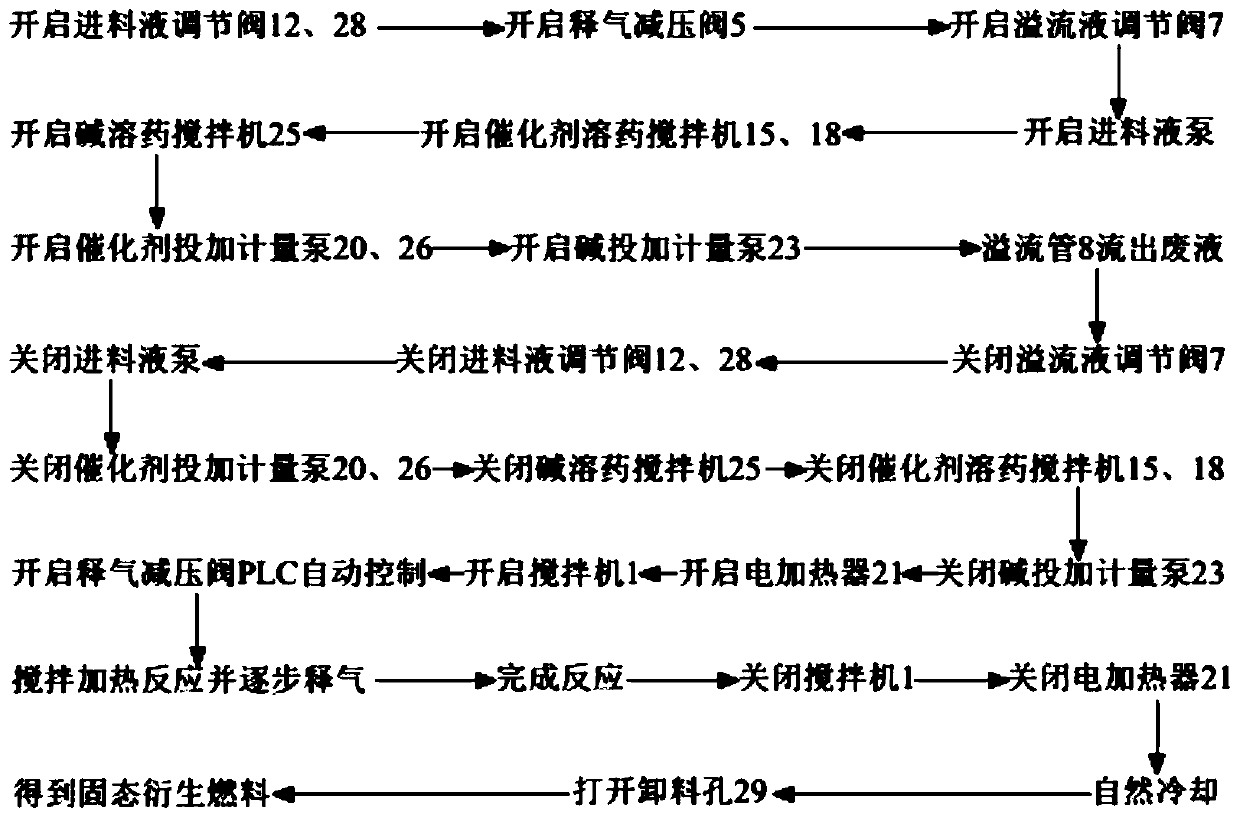

Embodiment 1

[0039] The high-concentration organic waste liquid in this example is taken from a company’s high-boiling point distillation raffinate. It is viscous in appearance and poor in water solubility. The COD is as high as hundreds of thousands mg / L. Advanced oxidation methods such as ozone and Fenton have been used in the early stage. Neither can obtain significant COD removal effect. The decompression degassing-catalytic carbonization technology proposed in this embodiment is used to treat this kind of high-concentration residual liquid. The specific methods and steps are: (1) injecting high-concentration organic waste liquid into the decompression degassing-catalytic carbonization device; (2) Pyrite powder and MnO 2 Dosing into the decompression degassing-catalytic carbonization device; the dosage of pyrite powder is 1.0g / (L organic waste liquid), MnO 2 The powder dosage is 0.1g / (L organic waste liquid); (3) Add sodium hydroxide to the device to adjust the pH of the waste liquid ...

Embodiment 2

[0043] The furfuryl alcohol production wastewater of a chemical company contains a large amount of furfuryl alcohol, phenolic aldehyde, furfural, and methanol, and the COD is as high as 200,000 to 300,000 mg / L. It is difficult to meet the discharge standard of the factory area (COD ≤ 500 mg / L) with the traditional combination of physicochemical and biochemical processes. Therefore, it is considered to convert most of the COD in wastewater into solid solid derived fuels by using the decompression degassing-catalytic carbonization method proposed in this example. The specific implementation method is: (1) inject high-concentration organic waste liquid into the decompression degassing-catalytic carbonization device; (2) catalyst pyrite powder and MnO 2 The dosage is 0.8g / (L organic waste liquid) and 0.1g / (L organic waste liquid); (3) Add sodium hydroxide to the device to adjust the pH of the waste liquid to 8.5; (3) Adjust the pH of the waste liquid to 8.5; Heat to 190°C, stir an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com