Miso preparation method capable of increasing aroma by utilizing saccharomyces rouxii

A technology of Saccharomyces ruckeri and Saccharomyces ruckeri, which is applied in the direction of food science, etc. It can solve problems such as high temperature, poor flavor, and increase starch content in koji, and achieve the effects of improving sensory indicators, efficient fermentation process, and soft aroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

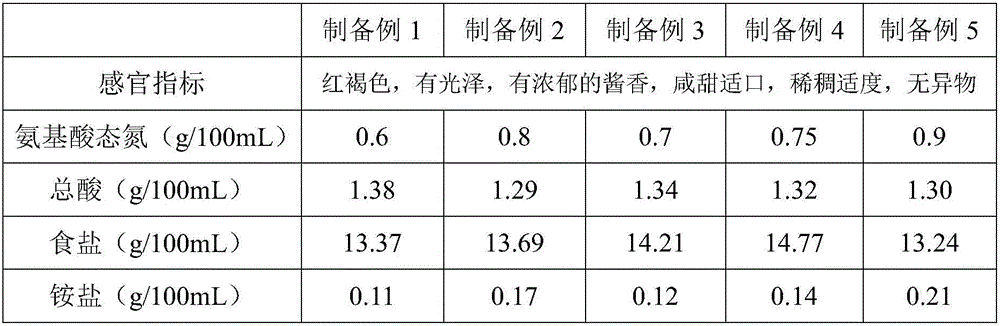

[0033] Preparation Example

[0034] Follow the steps below to prepare miso:

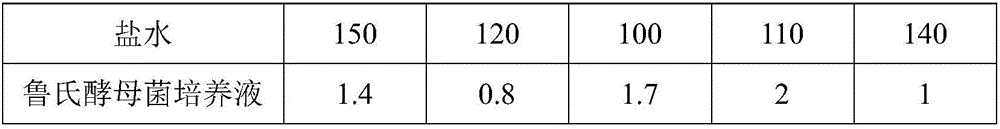

[0035] (1) Prepare materials: prepare materials according to the components shown in Table 1;

[0036] (2) Steaming and crushing: After the soybean meal is fully moistened, steam it under high pressure. The pressure of the steaming material is 0.03-0.18Mpa. After maintaining the pressure for 3-5 minutes, the moisture content of the clinker is 47-49%. The clinker requires moderate protein denaturation. , the color is light yellow, the texture is loose, the hand feels elastic, not sticky and has no hard core, and then the clinker is crushed, and the particle size of the crushed clinker is 2-6mm;

[0037] (3) Inoculation: the pulverized clinker obtained in step (2) is cooled to 38-40° C., mixed with flour and koji essence to make koji-making materials;

[0038] (4) koji making: the koji making material obtained in step (3) is sent to the koji bed to be flattened, and cultivated statically at 32-35°C. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com