An energy-saving feed processing pellet machine

A technology of feed processing and pellet machine, which is applied in the direction of feed, food science, application, etc., can solve the problems that the power system cannot realize multi-stage speed change, affect the service life of the equipment, adjust the power output, etc., achieve uniform force, improve torque, The effect of saving power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

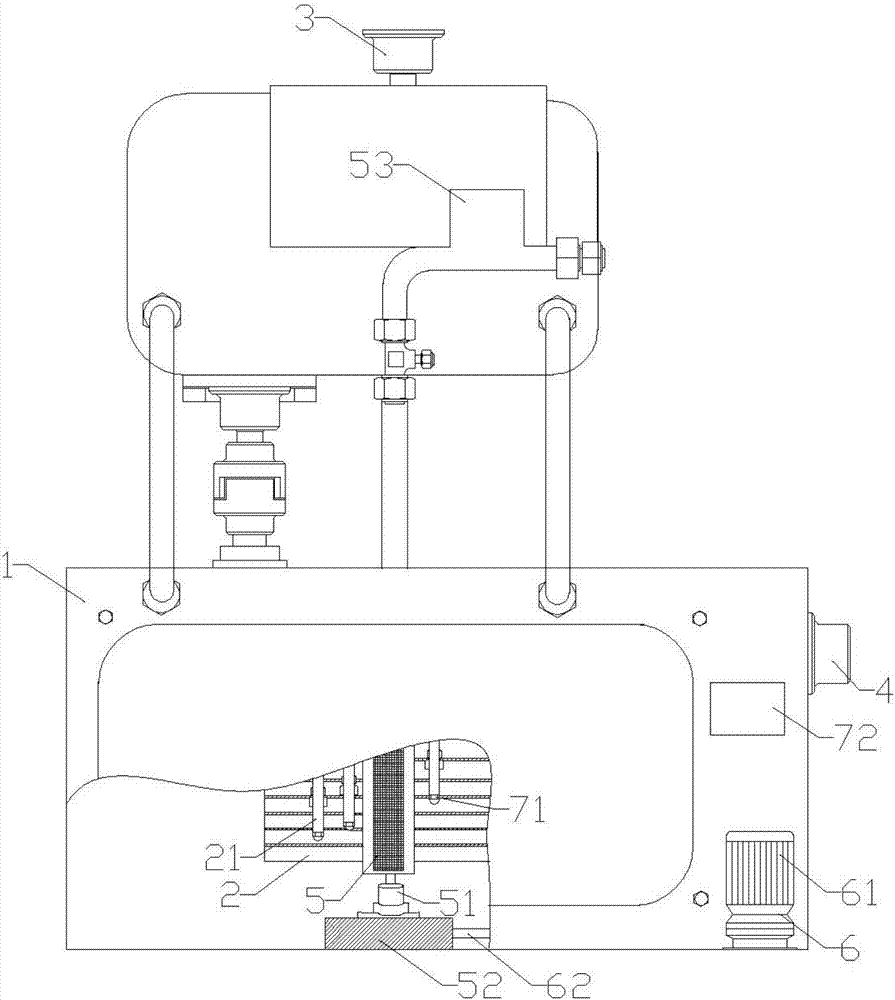

[0026] An energy-saving feed processing pellet machine, comprising: a housing 1, a ring die 2, a feed port 3, a feed port 4, a rotating shaft 5, a driving device 6, a pressure self-adjusting device 7 (not shown in the figure, which is controlled by pressure Sensor 71, pressure regulating controller 72 and wireless communication unit).

[0027] The casing 1 is separated by the ring die 2 into two areas, namely the material extrusion area in the ring die 2 and the pelletizing area outside the ring die 2; the material extrusion area is connected with the inlet and the outlet The pellet area is connected with the discharge port.

[0028] The ring die 2 has two working faces, and the two working faces can have two different compression ratios, and can work normally when the compression ratio required by the raw material is too large. The two working faces of the ring die 2 The installation dimensions are the same and can be turned over and used; when the first working surface is worn, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com