A kind of seam welding machine for oil drum and its processing method

A seam welding machine, oil drum technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of low work efficiency, non-working welding wheel, etc., to improve work output, ensure continuous operation, and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be described in further detail below in conjunction with the accompanying drawings.

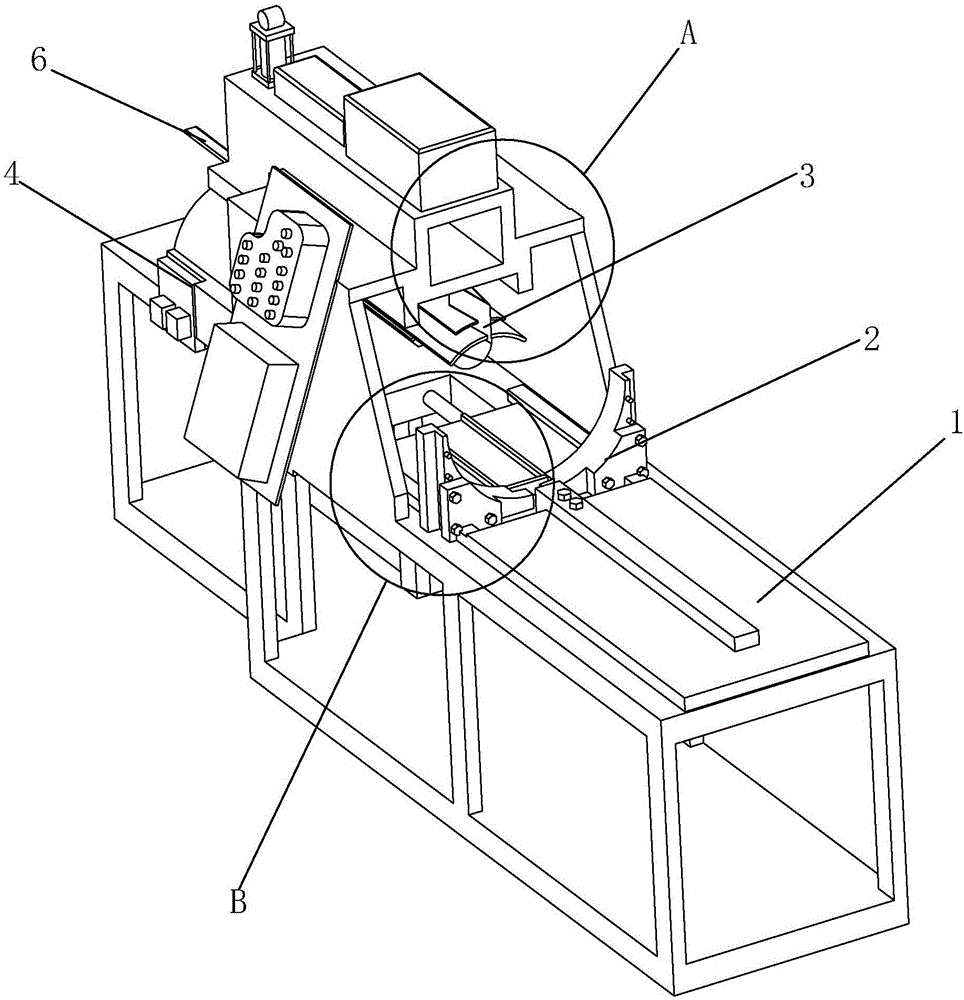

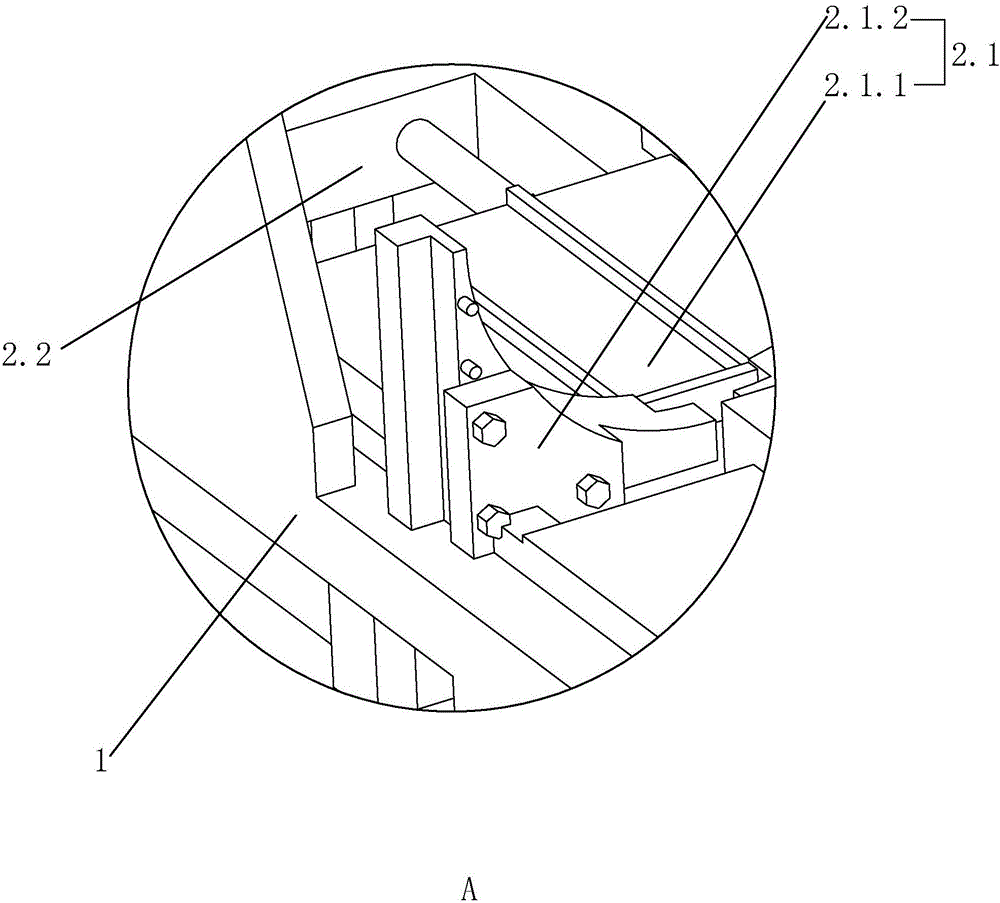

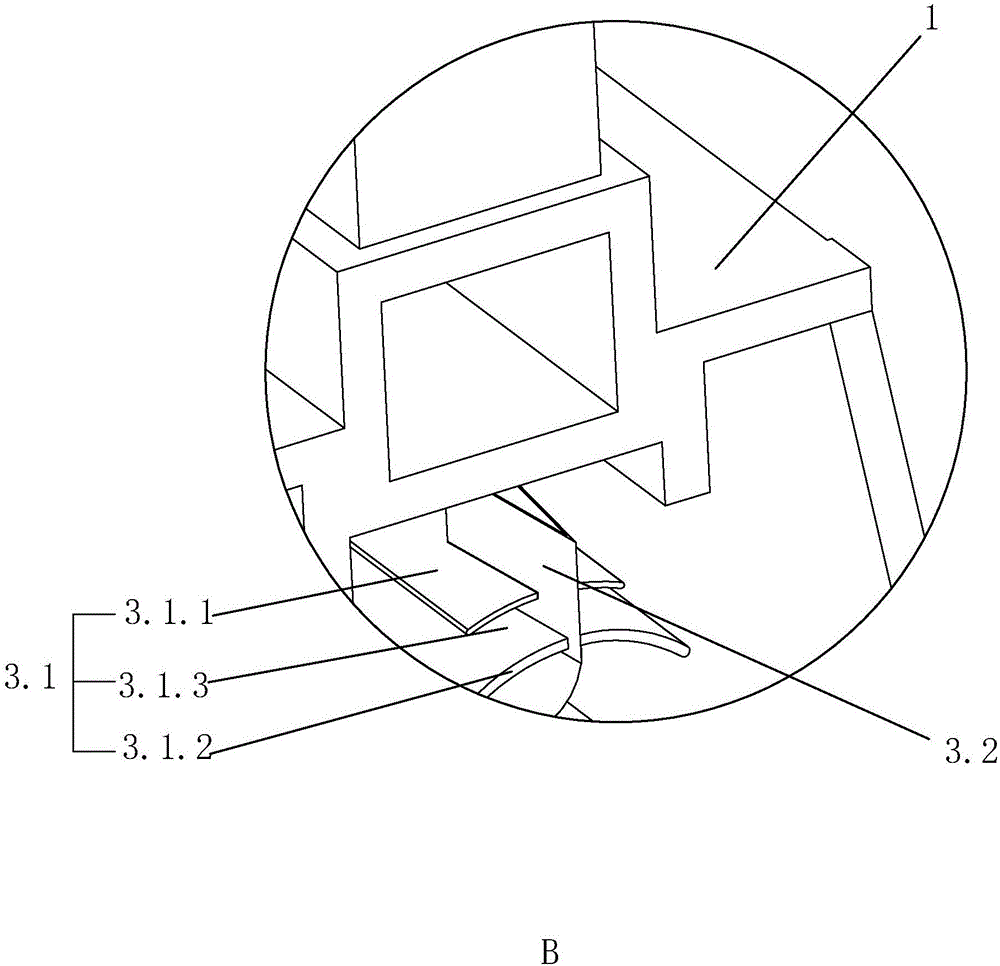

[0049] refer to figure 1 , image 3 , a kind of seam welding machine for oil drums, a placement plate is arranged on the right side of the fuselage 1 for placing the oil drums to be processed, and a diversion station 3 is arranged on the upper end of the fuselage 1, wherein the positioning of the diversion station 3 The clamping plate 3.1 is arranged on the upper end of the fuselage 1, and below the positioning clamping plate 3.1 is the claw seat 2.1 in the push station 2, so that when the oil drum is placed, the side walls of the upper end of the oil drum are placed on the positioning clamping plate 3.1, and the lower end is left standing On the base 2.1.1, a diverter plate 3.2 is also arranged at the middle end of the positioning clamp 3.1 at the same time, in order to prevent the two side walls of the metal ring of the oil barrel from overlapping together...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com