Hot wind edge covering structure and method for interior top lining skylight

A car sunroof and wrapping technology, which is applied in the automotive field, can solve the problems of polluting products, large space occupation, and high heat loss, and achieve the effect of small heat loss, large temperature loss, and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Embodiment of the present invention is described below in conjunction with accompanying drawing, embodiment does not constitute limitation of the present invention:

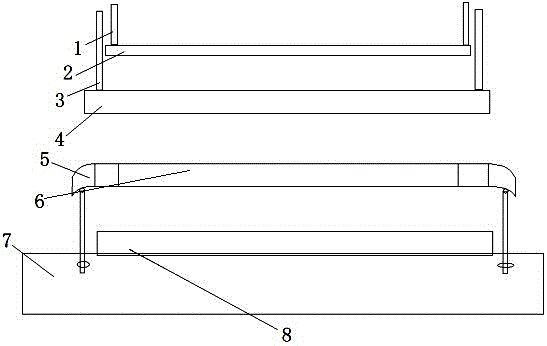

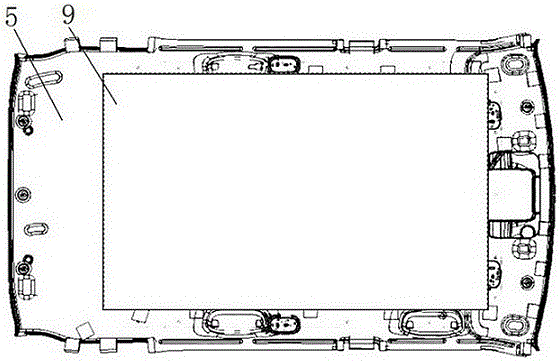

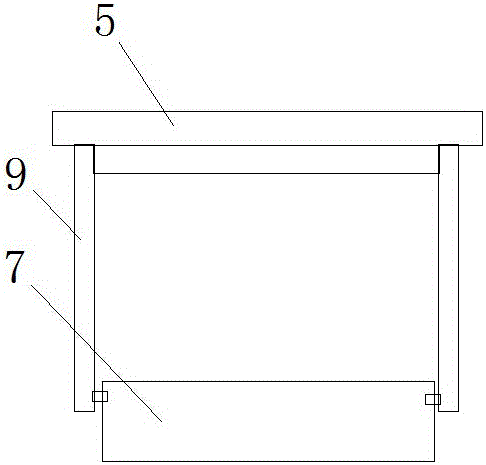

[0027] The hot air hemming structure of the roof lining skylight in the car is characterized in that it includes a main frame, the main frame includes a bottom clamp, and the bottom clamp includes a hemming module, and the hemming module can move downward to compress the material, The top of the hemming module includes a pressing part and a heating part, the pressing part is a lower pressing shaft, and the lower pressing shaft includes a pressing structure, which can be pressed against the hemming module, and the heating part includes a hot air connecting pipe, The hot air connecting pipe is connected to the hot air copper pipe below. The hot air copper pipe can be put down and placed above the edge wrapping module. The middle part of the edge wrapping module contains the corresponding opening of the skylig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com