A kind of flaky graphene oxide GO without high temperature oxidation process and preparation method thereof

A high-temperature oxidation, graphene technology, applied in graphene, chemical instruments and methods, inorganic chemistry and other directions, to achieve the effect of high degree of oxidation, good application prospects, and narrow thickness distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] In step 1, 115 mL of concentrated H 2 SO 4 Put it in a conical flask, place the conical flask in a low-temperature thermostat, cool down to 0°C and keep the temperature for 35min; Add 5g of graphite, 5g of sodium nitrate and 15g of potassium permanganate in sequence, and stir at a constant temperature of 0°C to obtain a mixed solution;

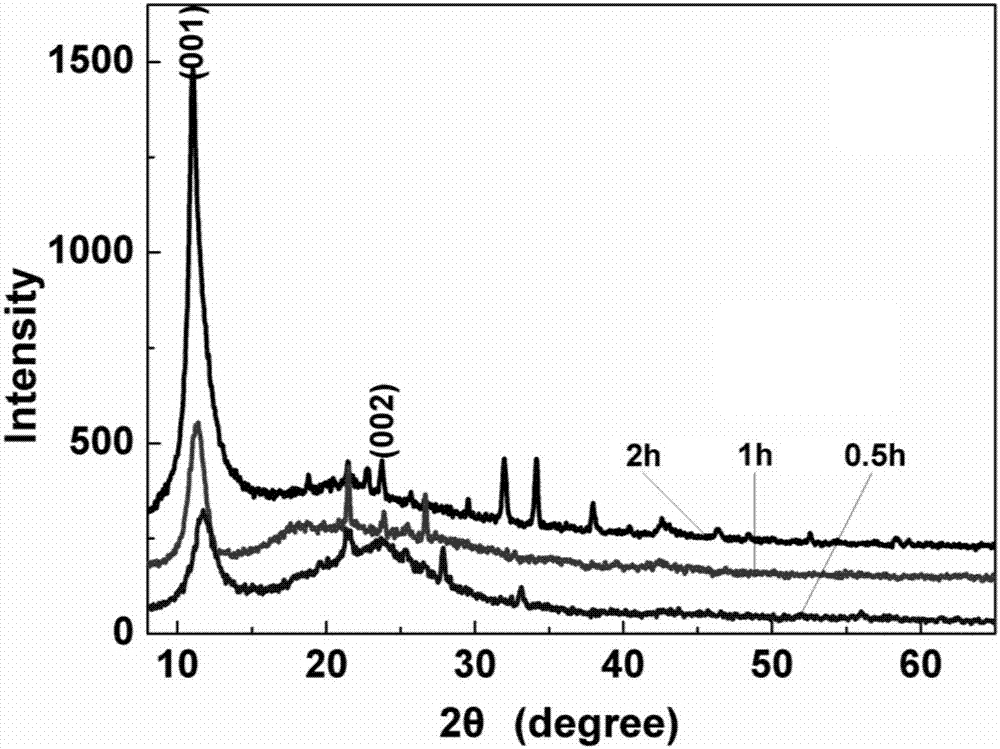

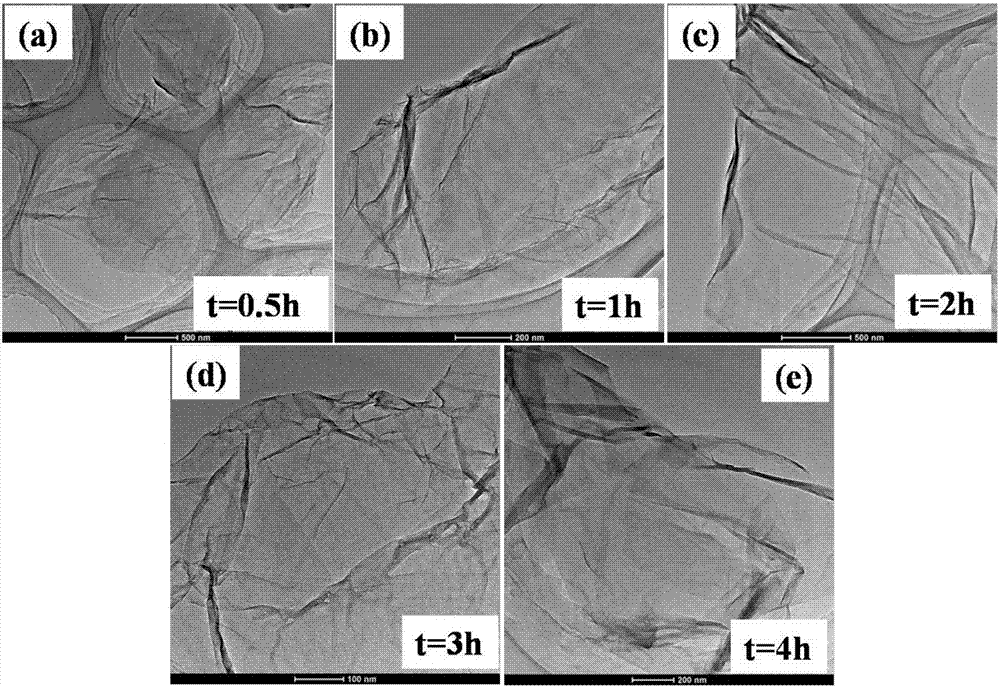

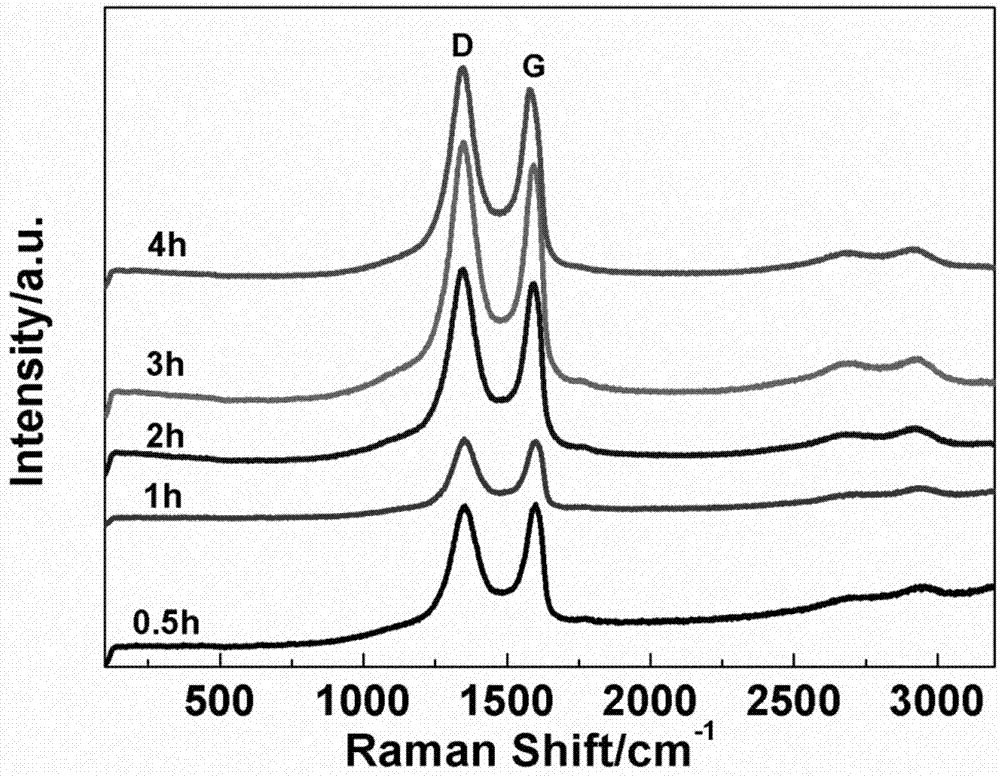

[0031] Step 2: Under stirring conditions, the temperature of the mixture is raised to 25°C at a heating rate of 3°C / min, and the stirring is continued for 3 hours;

[0032] Step 3, under stirring conditions, continue to heat the mixture to 35°C at a heating rate of 3°C / min, continue to stir and keep it warm for oxidation for 2 hours;

[0033] Step 4: Under stirring conditions, cool the mixed solution to 0 °C at a cooling rate of 3 °C / min, then keep stirring and keep the temperature constant for 2 hours, then add 400 mL of deionized water to the mixed solution at a rate of 20 mL / min, interval After 30 min, continue to add 60 mL of H t...

Embodiment 2

[0037] In step 1, 115 mL of concentrated H 2 SO 4 Put it in a conical flask, place the conical flask in a low-temperature thermostat, cool down to 0°C and keep the temperature for 35min; Add 5g of graphite, 5g of sodium nitrate and 15g of potassium permanganate in sequence, and stir at a constant temperature of 0°C to obtain a mixed solution;

[0038] Step 2: Under stirring conditions, the temperature of the mixture is raised to 25°C at a heating rate of 3°C / min, and the stirring is continued for 3 hours;

[0039] Step 3, under stirring conditions, continue to heat the mixture to 35°C at a heating rate of 3°C / min, continue to stir and keep warm for oxidation for 0.5h;

[0040] Step 4: Under stirring conditions, cool the mixed solution to 0 °C at a cooling rate of 3 °C / min, then keep stirring and keep the temperature constant for 2 hours, then add 400 mL of deionized water to the mixed solution at a rate of 20 mL / min, interval After 30 min, continue to add 60 mL of H to the ...

Embodiment 3

[0044] In step 1, 115 mL of concentrated H 2 SO 4 Put it in a conical flask, place the conical flask in a low-temperature thermostat, cool down to 0°C and keep the temperature for 35min; Add 5g of graphite, 5g of sodium nitrate and 15g of potassium permanganate in sequence, and stir at a constant temperature of 0°C to obtain a mixed solution;

[0045] Step 2: Under stirring conditions, the temperature of the mixture is raised to 25°C at a heating rate of 3°C / min, and the stirring is continued for 3 hours;

[0046] Step 3, under the condition of stirring, continue to heat the mixed solution to 35°C at a heating rate of 3°C / min, continue to stir and keep it warm for oxidation for 1h;

[0047] Step 4: Under stirring conditions, cool the mixed solution to 0 °C at a cooling rate of 3 °C / min, then keep stirring and keep the temperature constant for 2 hours, then add 400 mL of deionized water to the mixed solution at a rate of 20 mL / min, interval After 30 min, continue to add 60 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| oxidation state | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com