Oil refining alkaline residue acidification reactor and acidification method thereof

A reaction device and a technology for refining soda slag, which is applied to the acidification reaction device of oil refining soda slag and its acidification field, can solve problems such as device and pipeline blockage, achieve high-efficiency air bubbles, enhance gas-liquid mass transfer and return mixed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

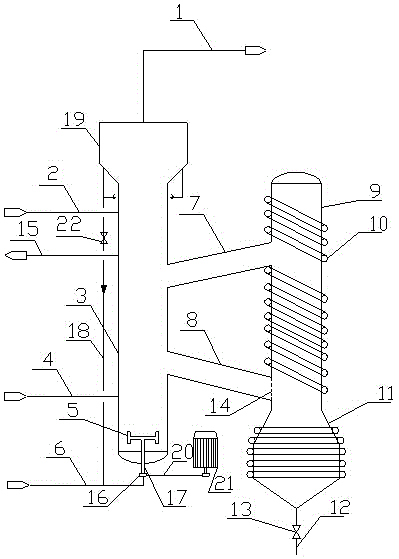

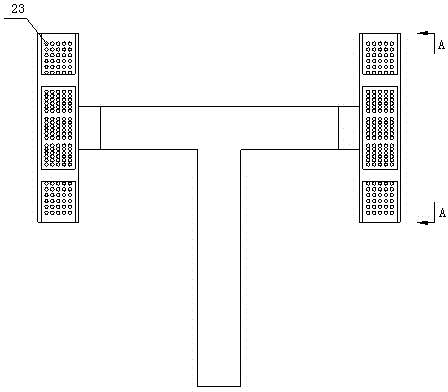

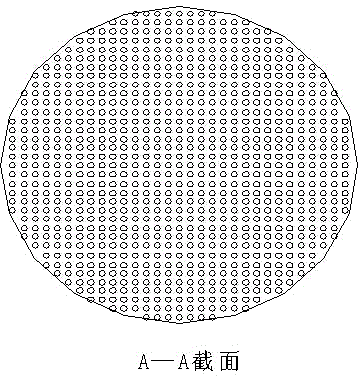

[0035] Catalytic gasoline alkali residue in a refinery, of which COD is 3.21×10 5 mg / L, sulfide is 1.76×10 4 mg / L. with attached figure 1 The acidification reaction device is acidified, and the height-diameter ratio of the reaction tower and the condensation tower is 15 and 10 respectively; The angle of 30° is connected to the two towers, and the communication port of the condensation tower is lower than the communication port of the reaction tower; the lower connecting pipe is connected to the two towers at a horizontal angle of 45°, and the communication port of the condensation tower is higher than the communication port of the reaction tower. The acidification reaction tower adopts a cylindrical reaction tower, the upper end is set into a conical shape, one end of the bubble suction pipe is connected to the conical surface of the conical tower wall at the upper end of the reaction tower, and there are 6 bubble suction pipes, which are evenly distributed and symmetrically...

Embodiment 2

[0037] Liquid hydrocarbon alkali residue of a refinery, of which COD is 7.97×10 4 mg / L, sulfide is 4×10 3 mg / L. with attached figure 1 The acidification reaction device is acidified, and the height-diameter ratios of the reaction tower and the condensing tower are 18 and 12 respectively; the diameter of the upper connecting pipe and the lower connecting pipe is 0.8 times the diameter of the reaction tower, and the upper connecting pipe and the horizontal angle are 50 °Connected with the two towers, the condensing tower communication port is lower than the reaction tower communication port; the lower connecting pipe is connected with the two towers at a 50° horizontal angle, and the condensation tower communication port is higher than the reaction tower communication port. The acidification reaction tower adopts a cylindrical reaction tower, the upper end is set into a conical shape, one end of the bubble suction pipe is connected to the conical surface of the conical tower w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com