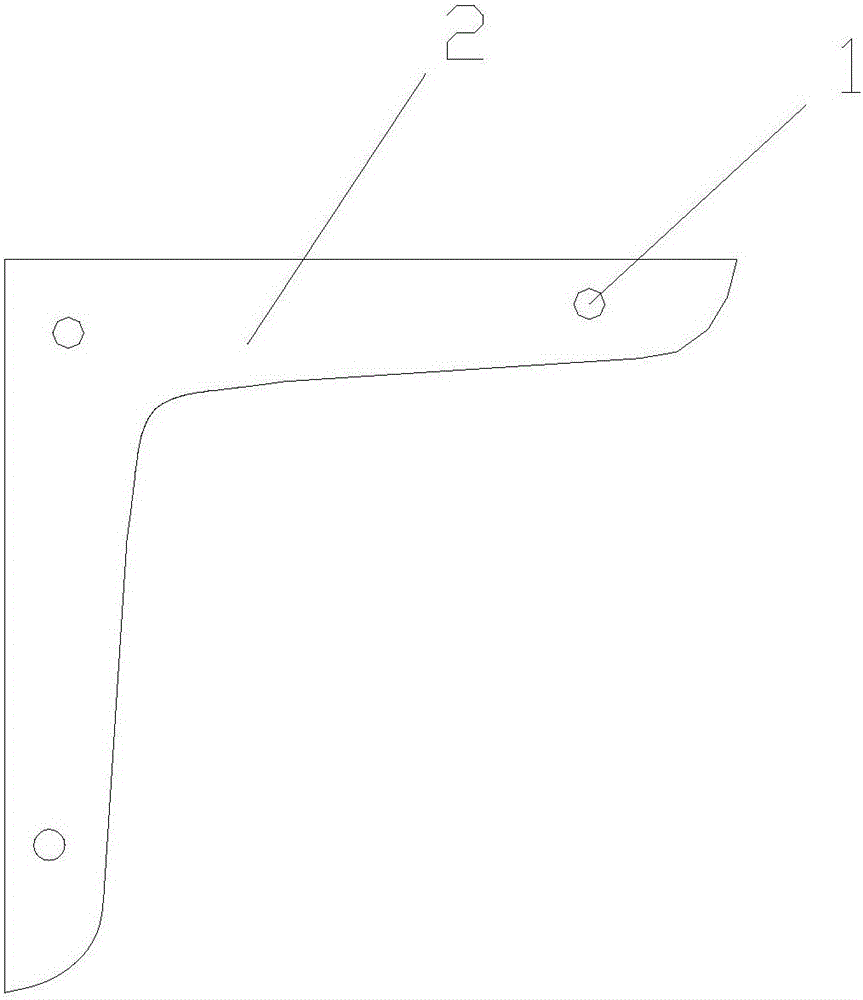

Production technology of carbon fiber composite angle steel

A production process and compound angle technology, which is applied in the production process field of carbon fiber composite angle steel, can solve the problems of complex forming process, and achieve the effects of uniform distribution, high product quality and low price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical means realized by the present invention, the novel features created, the purpose achieved and the effects achieved clearly understood, the present invention will be further elaborated below in conjunction with specific examples.

[0024] A production process of carbon fiber composite angle steel, comprising the following steps,

[0025] 1), prepare materials, 3 bundles of carbon fiber filament materials, unsaturated resin, catalyst, pigment and stabilizer;

[0026] 2) To melt, heat the unsaturated resin to 60°C to soften for 30 minutes, then add the pigment and mix thoroughly, then raise the temperature to 80°C and keep it warm for 20 minutes;

[0027] 3) Immersion, raise the temperature of the unsaturated resin to 105°C, first add the stabilizer and then the catalyst and mix them well separately, arrange the ends and sides of the carbon fiber filament material in a straight shape, and then immerse in the unsaturated resin and pass slowly;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com