Design method for coal reservoir transformation

A technology of coal reservoirs and coal seams, which is applied in the design field of reformed coal reservoirs, can solve problems such as high Poisson's ratio, blocked seepage channels, and low Young's modulus, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

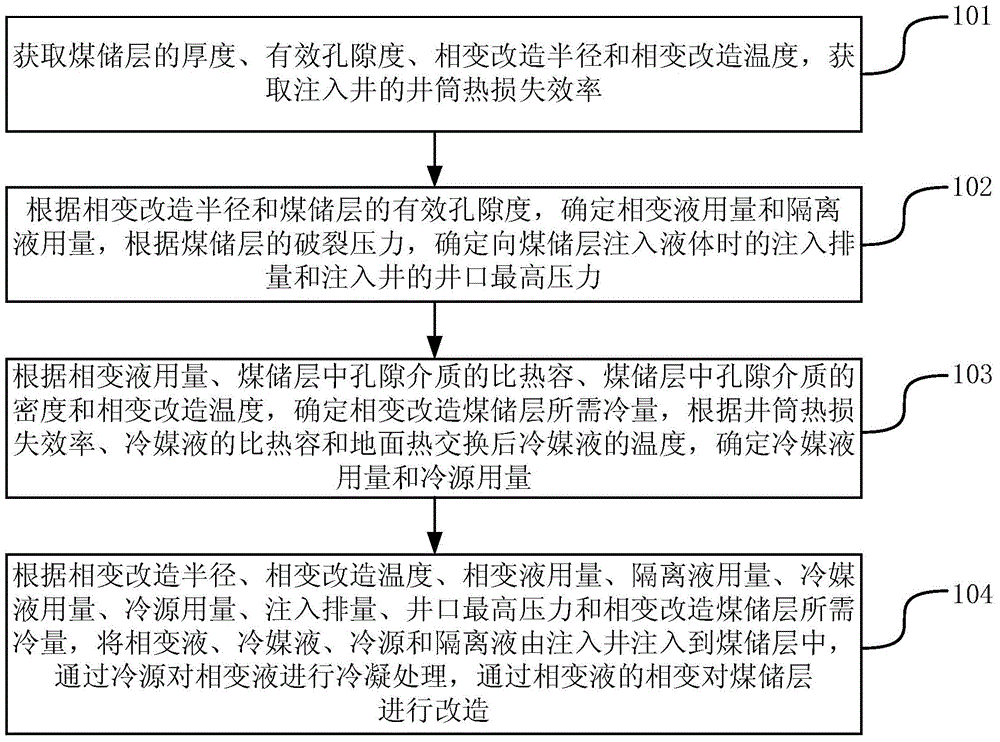

[0036] Embodiments of the present invention provide a design method for transforming coal reservoirs, such as figure 1 As shown, the processing flow of the method may include the following steps:

[0037] In step 101, the thickness, effective porosity, radius of phase change modification and phase change modification temperature of the coal reservoir are obtained, and the wellbore heat loss efficiency of the injection well is obtained.

[0038] Step 102, according to the transformation radius of the phase change and the effective porosity of the coal reservoir, determine the amount of the phase change fluid and the spacer fluid, and according to the fracture pressure of the coal reservoir, determine the injection displacement and injection well volume when injecting liquid into the coal reservoir The maximum wellhead pressure.

[0039] Step 103, according to the amount of phase change fluid, the specific heat capacity of the pore medium in the coal reservoir, the density of t...

Embodiment 2

[0043] Embodiments of the present invention provide a design method for transforming coal reservoirs. figure 1 The processing flow shown is described in detail, and the content can be as follows:

[0044] In step 101, the thickness, effective porosity, radius of phase change modification and phase change modification temperature of the coal reservoir are obtained, and the wellbore heat loss efficiency of the injection well is obtained.

[0045] Wherein, the coal reservoir may be any coal reservoir for storing coal, and a plurality of injection wells for injecting liquids such as phase change fluid may be arranged above the coal reservoir.

[0046] In practice, the special structure of the coal reservoir often causes a large amount of coalbed methane (such as gas) to be adsorbed in the coal reservoir, and the permeability of the coal reservoir is usually low, which makes the production capacity of the coalbed methane low. In order to improve To increase the production capacity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com