Multi-stage atomization type two-phase flow water mist generation device for controlling coal field fire

A generating device and two-phase flow technology, applied in fire prevention, safety devices, dust prevention, etc., can solve the problems of affecting the effect of fine water mist fire extinguishing and cooling, difficult to carry and carry, and large droplet size, etc., to achieve improved Operability and portability, increase the degree of atomization, the effect of high degree of atomization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

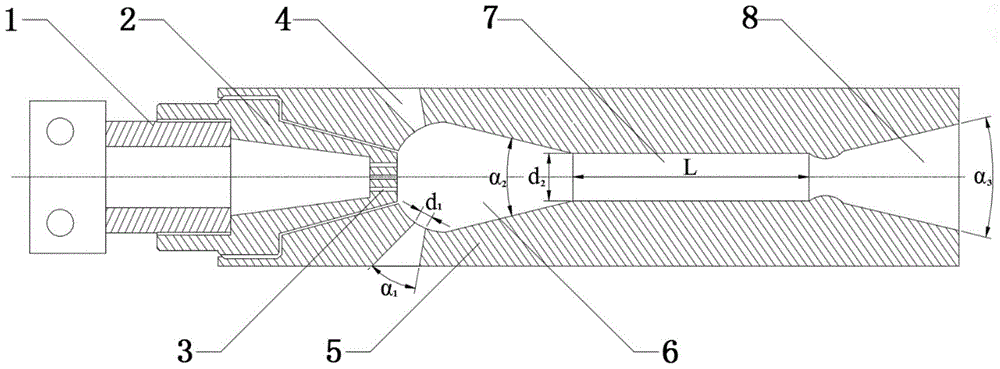

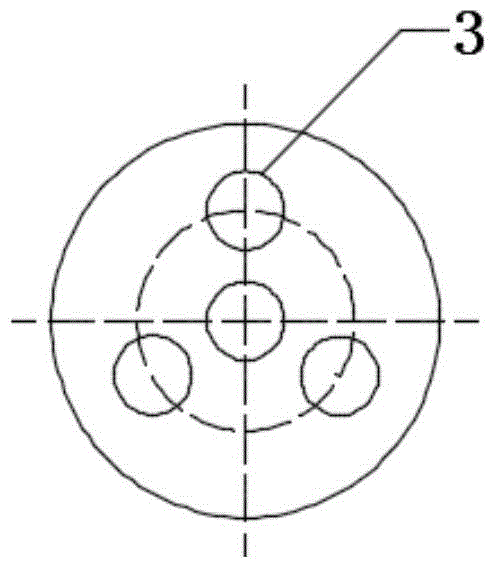

[0019] Such as figure 1 As shown, the multi-stage atomization type two-phase flow fine water mist generating device for preventing and controlling coalfield fires of the present invention is mainly composed of a pressure water supply pipe 1, a multi-hole nozzle 2 and a jet atomization cylinder 5. The jet atomization Inside the barrel 5, there are successively an impingement atomization chamber 6, a mixing acceleration chamber 7, and a diffusion spray chamber 8; the pressure water supply pipe 1 is threaded on the multi-hole nozzle 2, and the multi-hole nozzle 2 is threaded on the jet atomizer On the cylinder body 5, the injection end of the multi-hole nozzle 2 communicates with the impingement atomization chamber 6 inside the jet atomization cylinder body 5 through the nozzle hole 3. 5. The end of the impact atomization chamber 6 close to the porous nozzle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Minimum inner diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com