Forced guiding multistage rotation pressing flame ash separating structure for cooking furnace

A technology of forced orientation and separation structure, which is applied in the direction of household stoves/stoves, lighting and heating equipment, solid heating fuels, etc. It can solve the problems of heat loss, reduction of thermal efficiency of finishing, and treatment of light ash and slag, and achieve an increase in heat exchange rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0011] Specific implementation manners: the present application is not limited by the following examples, and specific implementation manners can be determined according to the technical solutions of the present invention and actual conditions.

Embodiment

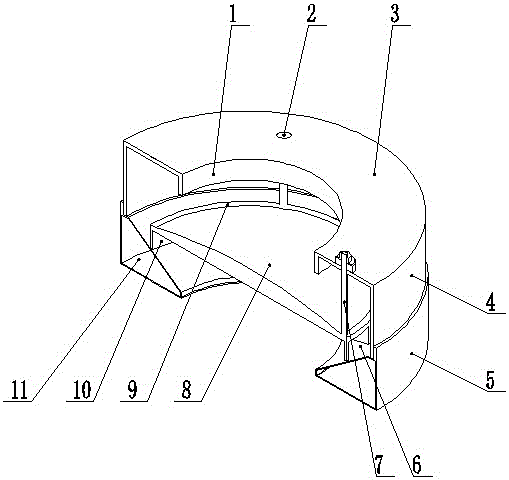

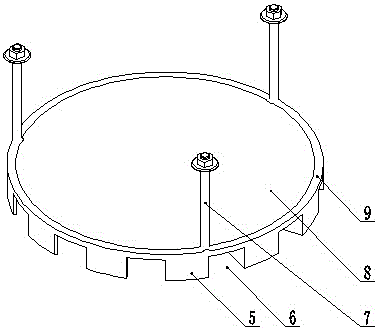

[0012] Example: such as figure 1 As shown, the forced-guided multi-stage rotary pressing fire ash separation structure of the cooking stove includes a flame collection box 11, which is a cavity ring, and a cavity secondary guide ring for guiding the direction of the flame is communicated above it. A primary deflector for dispersing flames is arranged between the secondary deflector ring and the flame collection box 11 . The secondary diversion ring includes diversion inner and outer rings 1 and 4, and the upper ends of the diversion inner and outer rings 1 and 4 are covered with a secondary diversion cover plate 3, and the primary diversion plate includes an annular ring frame 9. A first-stage diversion cover plate 8 is arranged inside the ring frame 9 , and a circle of diversion rings 10 is arranged on the outer circumference of the lower end surface of the first-stage diversion cover plate 8 , and diversion ports 6 are provided at equidistant intervals on the diversion ring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com