Biogas project gas production test system

A test system and gas production technology, applied in the energy field, can solve the problems of poor applicability, lack of lateral comparability of gas production measurement values, and insufficient accuracy, so as to overcome insufficient accuracy, stable and reliable measurement results, The effect of simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

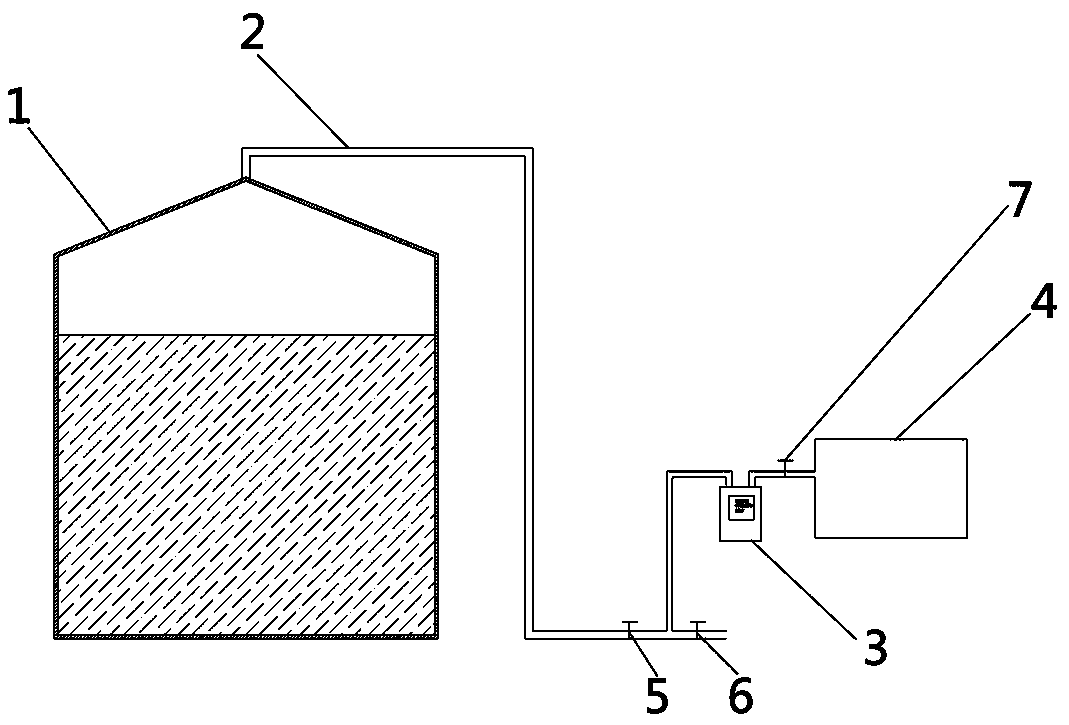

[0021] The gas production test system of the biogas project in this example is composed of a precision flowmeter 3 and a soft bag 4. One end of the precision flowmeter 3 is connected to the original measuring interface on the gas pipeline 2, and the other end is connected to the soft bag 4 through a valve 7.

[0022] The precision flowmeter 3 is a precision flowmeter capable of measuring gas flow, gas pressure and gas temperature.

[0023] The method of using the gas production test system of this biogas project is as follows:

[0024] First close the valve 5 and valve 6 at both ends of the original measuring interface on the gas pipeline 2, close the valve 7, connect one end of the precision flow meter 3 to the original measuring interface on the gas pipeline 2, and connect the other end to the soft bag 4 through the valve 7 connect;

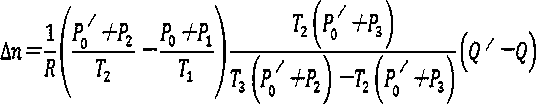

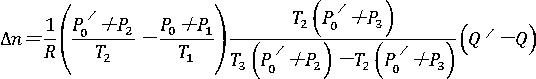

[0025] Open the valve 5 and read the atmospheric pressure P after the precision flow meter 3 stabilizes 0 , biogas pressure P 1 , temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com