Polarization-insensitive photic driving tunable TeraHertz wave metamaterial absorber

A polarization-insensitive, light-driven technology used in terahertz applications, which can solve problems such as high absorption fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

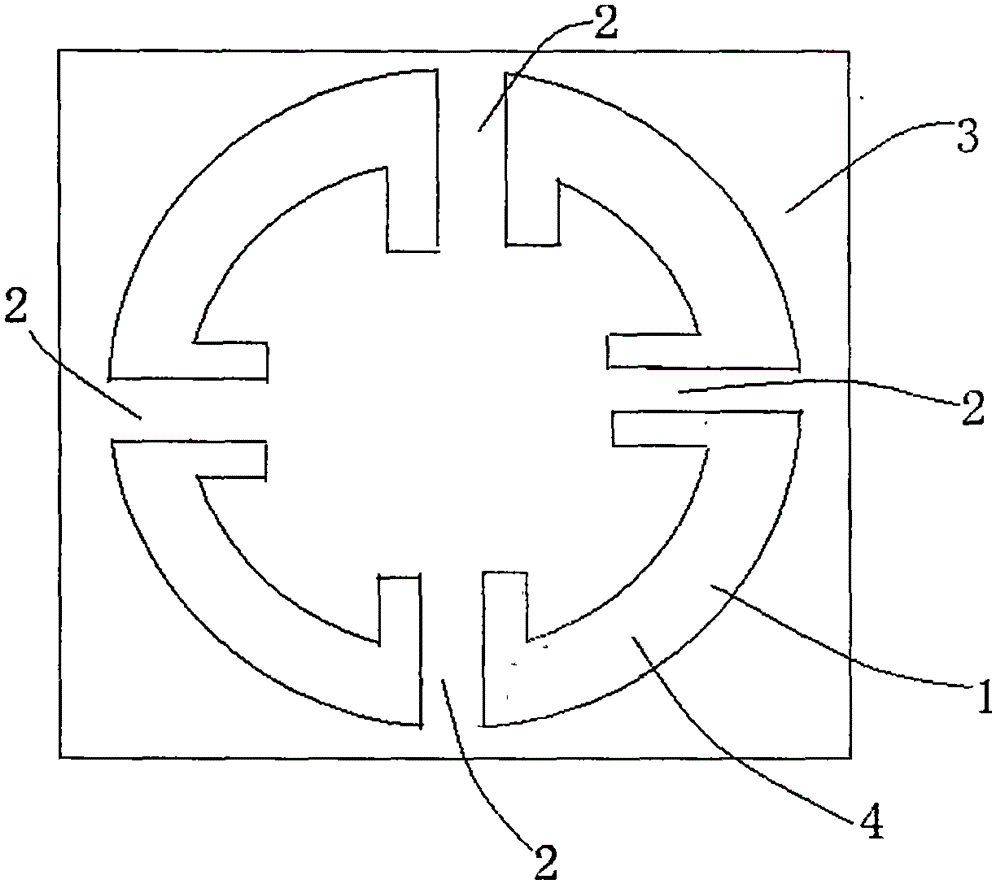

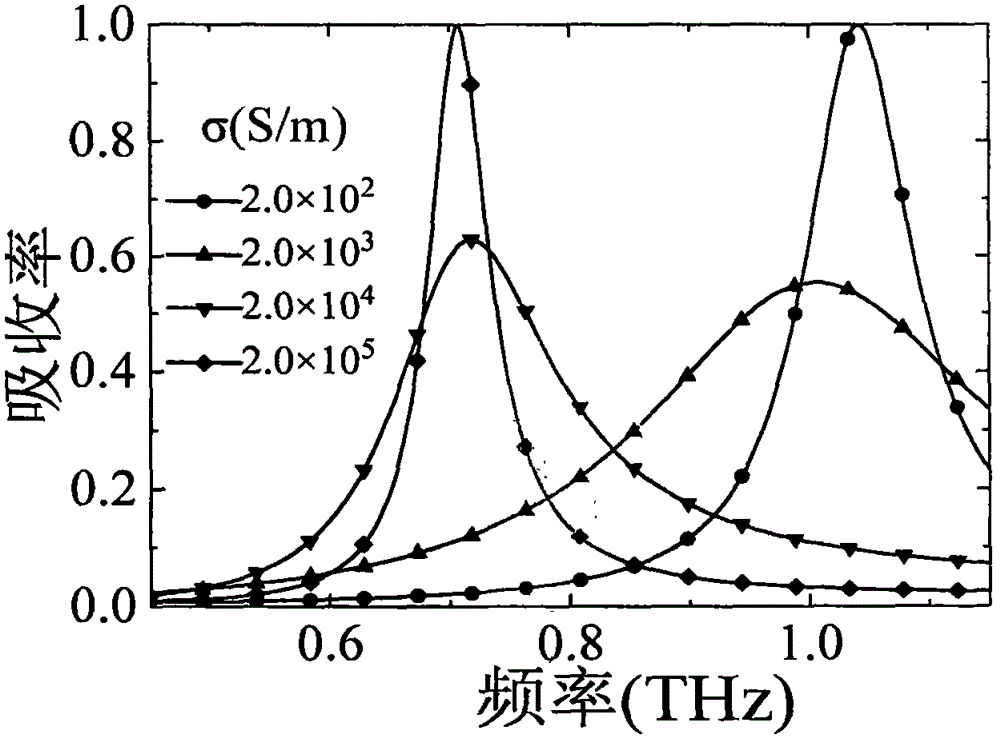

[0035] Example 1, such as figure 1 and figure 2 As shown, the absorber consists of a dielectric substrate 3, a metal pattern layer 4 etched on the dielectric substrate 3 (circular metal slotted ring resonator structure), semiconductor silicon Si embedded in the slotted ring structure, and semiconductor silicon Si conductance The rate σ varies with the light power, and the metal backplane is composed of the figure 1 In the unit structure, the length and width of the first cycle are both p, the outer ring radius of the circular slotted ring is r, the line width is w, the slot width is g, and the metal film thickness of the slotted ring structure is t m , the length of the semiconductor silicon filled at the opening of the slit ring is a. The thickness of the dielectric substrate is t s , the thickness of the metal base plate is t g , by changing the geometric parameters of the unit structure, it can work in different frequency ranges. The variation range of the structural ...

Embodiment 2

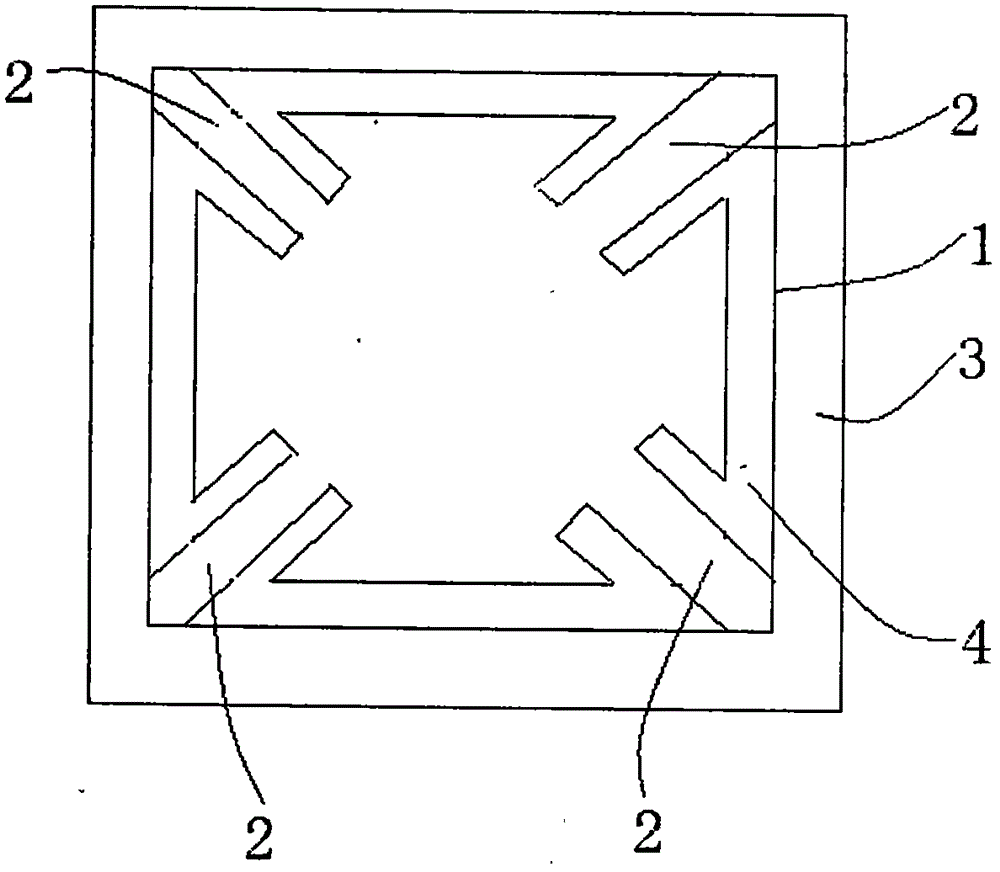

[0049] Example 2, such as image 3 and Figure 4 As shown, the absorber consists of a dielectric substrate 3, a metal pattern layer 4 etched on the dielectric substrate 3 (square metal slotted ring resonator structure), semiconductor silicon Si embedded on the metal pattern layer 4, and the conductivity of the semiconductor silicon Si σ varies with the light power, and is composed of a metal backplane, in which, the length and width of one period of the unit structure are p, the side length of the square is l, the line width is w, the slit width is g, and the metal film thickness of the slotted ring structure is tm, and the length of the semiconductor silicon filled at the opening of the slot ring is a. The thickness of the dielectric base plate is ts, and the thickness of the metal base plate is tg. By changing the geometric parameters of the unit structure, it can work in different frequency ranges. The variation range of the geometric parameters of the basic unit structur...

Embodiment 3

[0061] Embodiment 3, the absorber consists of a dielectric substrate, a metal pattern layer etched on the dielectric substrate (slotted cross-shaped resonator structure), semiconductor silicon Si embedded in the slotted cross, and the conductivity σ of the semiconductor silicon Si increases with The light power varies with the difference, and the metal backplane is composed, in which, the length and width of the unit structure period are p, the side length of the slotted cross is l, the side is w, the slot width is g, and the thickness of the slotted cross-shaped metal film is t m , the length of the semiconductor silicon filled at the cross-shaped opening of the groove is a. The thickness of the dielectric substrate is t s , the thickness of the metal base plate is t g , by changing the geometric parameters of the unit structure, it can work in different frequency ranges. The variation range of the structural geometric parameters of the basic unit of the absorber:

[0062]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com