Pre-cured convenient coarse cereals and preparation method thereof

A technology for pre-ripening and miscellaneous grains, applied in the field of miscellaneous grain processing, can solve the problems of high product cost, high equipment cost, hard taste, etc., and achieve the effects of low processing cost, short processing time and less water consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

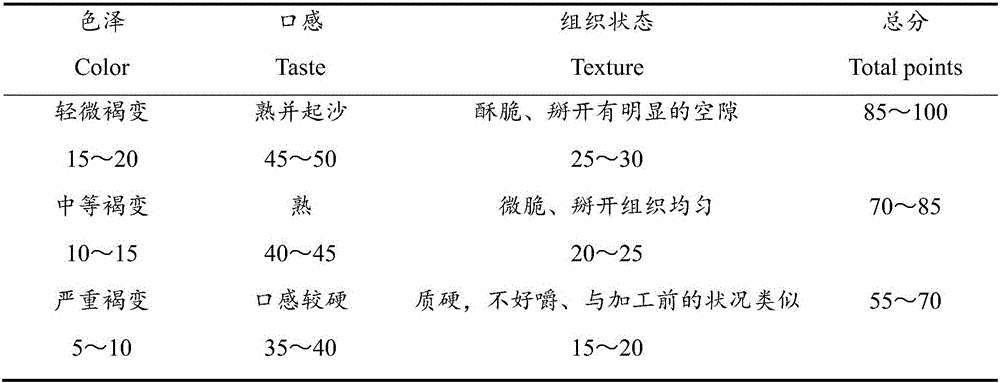

Image

Examples

Embodiment 1

[0030] The present embodiment provides a kind of preparation method of preferred precooked instant miscellaneous cereals, and the steps are as follows:

[0031] 1) Screen raw miscellaneous grains to remove impurities such as soil, straw and moldy particles in the miscellaneous grains;

[0032] 2) Mix and soak the miscellaneous grains and magnetized water obtained in step 1) according to the mass ratio of miscellaneous grains:magnetized water=1:1.5. The soaking time is 12 hours for red beans, 5 hours for black beans, 4 hours for mung beans, 3 hours for soybeans, 13 hours for kidney beans, and 6 hours for green beans. 8 hours for peas, 3 hours for brown rice, 3 hours for oats, 4 hours for sorghum, 9 hours for barley, 3 hours for barley kernels, 3 hours for barley kernels, 1 hour for black rice, and 1 hour for red rice. Dry at 60°C for later use;

[0033] 3) Put iron balls with a diameter of 2-5cm of the same volume as the miscellaneous grains into the frying equipment and prehe...

Embodiment 2

[0038] The present embodiment provides a kind of preparation method of preferred precooked instant miscellaneous cereals, and the steps are as follows:

[0039] 1) Carry out according to 1) in embodiment 1;

[0040] 2) Mix and soak the miscellaneous grains and magnetized water obtained in step 1) according to the mass ratio of miscellaneous grains:magnetized water=1:1.7. The soaking time is 12 hours for red beans, 5 hours for black beans, 4 hours for mung beans, 3 hours for soybeans, 13 hours for kidney beans, and 6 hours for green beans. 8 hours for peas, 3 hours for brown rice, 3 hours for oats, 4 hours for sorghum, 9 hours for barley, 3 hours for barley kernels, 3 hours for barley kernels, 1 hour for black rice, and 1 hour for red rice. Dry at 55°C for later use;

[0041] 3) Put iron balls with a diameter of 2-5cm of the same volume as the miscellaneous grains into the frying equipment and preheat to 170°C. Use iron balls with small diameters for miscellaneous grains with ...

Embodiment 3

[0045] The present embodiment provides a kind of preparation method of preferred precooked instant miscellaneous cereals, and the steps are as follows:

[0046] 1) Carry out according to 1) in embodiment 1;

[0047]2) Mix and soak the miscellaneous grains and magnetized water obtained in step 1) according to the mass ratio of miscellaneous grains:magnetized water=1:1.7. The soaking time is 12 hours for red beans, 5 hours for black beans, 4 hours for mung beans, 3 hours for soybeans, 13 hours for kidney beans, and 6 hours for green beans. 8 hours for peas, 3 hours for brown rice, 3 hours for oats, 4 hours for sorghum, 9 hours for barley, 3 hours for barley kernels, 3 hours for barley kernels, 1 hour for black rice, and 1 hour for red rice. Dry at 65°C for later use;

[0048] 3) Put iron balls with a diameter of 2-5cm of the same volume as the miscellaneous grains into the frying equipment and preheat to 220°C. Use iron balls with small diameters for miscellaneous grains with s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com