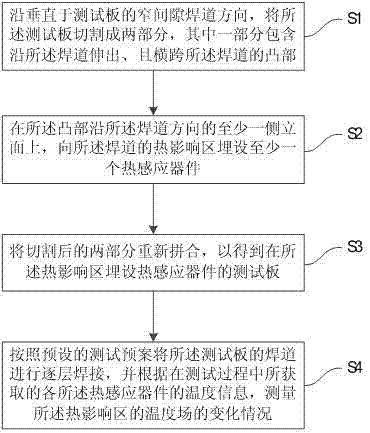

Measurement method and system for narrow gap welding temperature field

A welding temperature and measurement method technology, applied in the field of measurement, can solve problems such as inaccurate measurement of the welding temperature field, and achieve the effects of improving accuracy, welding efficiency, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

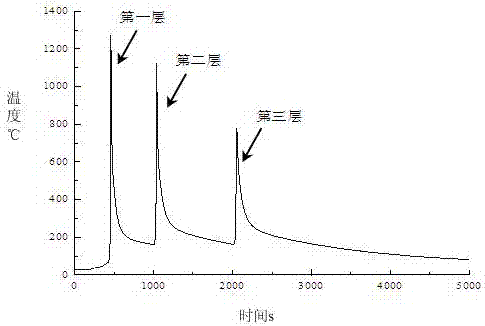

Examples

Embodiment 2

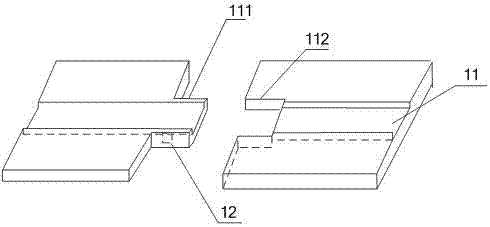

[0060] like figure 2 and 6 As shown, the present invention provides a measurement system for a narrow gap welding temperature field. The measurement system includes: a test board and test equipment 14 .

[0061] The test board includes: narrow-gap weld beads 11 , dividing traces 13 , and thermal induction devices 12 .

[0062] The narrow gap weld bead 11 usually has a width between 18-22 mm.

[0063] The dividing marks 13 are formed by cutting the test plate into two parts along the direction perpendicular to the narrow gap weld bead 11 and then splicing them together, one part of which includes extending along the weld bead 11 and crossing the weld bead. The other part of the convex part 111 of 11 includes a concave part 112 matched with the convex part 111 .

[0064] Take the offshore platform rack steel DILLIMAX690E (see Table 1 and Table 2 for chemical composition and mechanical properties) produced by German Dillingen Metallurgical Company as an example.

[0065] Ta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| microhardness | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com