Integrated temperature measurement type ceramic packaging tube shell

A technology of ceramic packaging tube shell and tube shell, which is applied in the direction of measuring device, fluid velocity measurement, electric solid device, etc. It has problems such as flow and heat conduction, and achieves the effect of reducing the volume, simplifying the packaging steps, and facilitating the volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

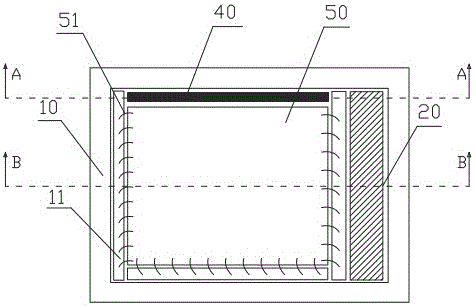

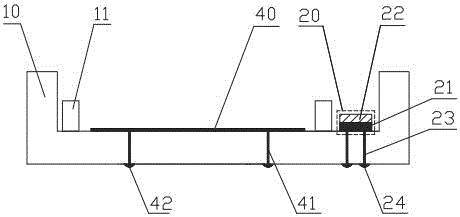

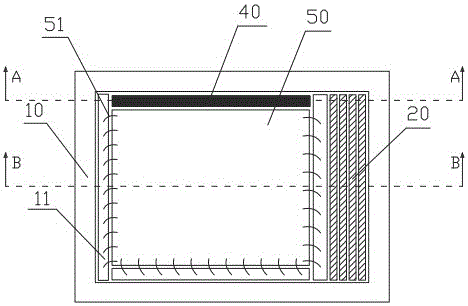

[0019] Embodiment 1: see figure 1 and figure 2 , an integrated temperature-measuring ceramic packaging case, including a ceramic packaging case 10, and a temperature-measuring module 40, the temperature-measuring module and the ceramic packaging case 10 are designed in an integrated manner. Specifically, the temperature measurement module is a thermocouple or thermal resistance temperature sensing area 40, and the thermocouple or thermal resistance temperature sensing area 40 is directly printed on the ceramic packaging tube through the metal paste printing process. On the inner surface of the shell, NTC thermistor material is preferably used, and a lead frame 41 connected to a thermocouple or a thermal resistance temperature sensing area 40 is reserved in the ceramic package shell 10, and the temperature of the thermocouple or thermal resistance is The sensing area is connected to the signal pin 42 outside the package through the lead frame 41 .

[0020] In the present inv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com