Evaporation treatment controlling method for wastewater from wet flue gas desulfurization

A technology for wet flue gas desulfurization and treatment control, applied in water treatment parameter control, gaseous effluent wastewater treatment, water/sewage treatment, etc., can solve the problem that the system stability cannot be guaranteed, real-time control and rule search cannot be performed Problems such as the expansion of the range, to achieve the effects of timely response to abnormal changes in smoke temperature, reducing hysteresis, and improving fault tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Below in conjunction with embodiment the present invention is described in further detail:

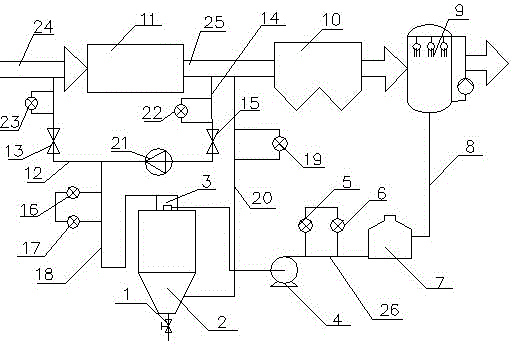

[0038] Such as figure 1 Shown is a schematic diagram of the desulfurization wastewater treatment plant

[0039] The desulfurization waste water drawn from the desulfurization tower 9 is stored in the liquid storage tank 7, and then the desulfurization waste water pump 4 is sprayed into the evaporation tower 2 through the pipe five 26 through the swirl nozzle 3 at the top of the evaporation tower 2, and from the front of the air preheater 11 The extracted flue gas enters the pipeline 1 12, and the flue gas flow rate is controlled by the valve 1 13. The flue gas extracted by the fan 21 from the air preheater 11 enters the pipeline 2 14 through the flue 1 24, and the flue gas flow rate is controlled by the valve 2 15 Control; after the two-way flue gas is mixed, it enters the pipeline three 18 and then is introduced into the evaporation tower 2. After evaporating the desulfurizati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com