Polymerization inhibitor for acrylic acid monomer refining

A technology of acrylic monomer and polymerization inhibitor, which is applied in the field of polymerization inhibitor for improving the continuous production cycle of acrylic monomer refining tower, can solve the problems of inability to effectively prevent polymers and block pipelines, and achieves improved continuous operation time and stable operation. , Improve the effect of continuous production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

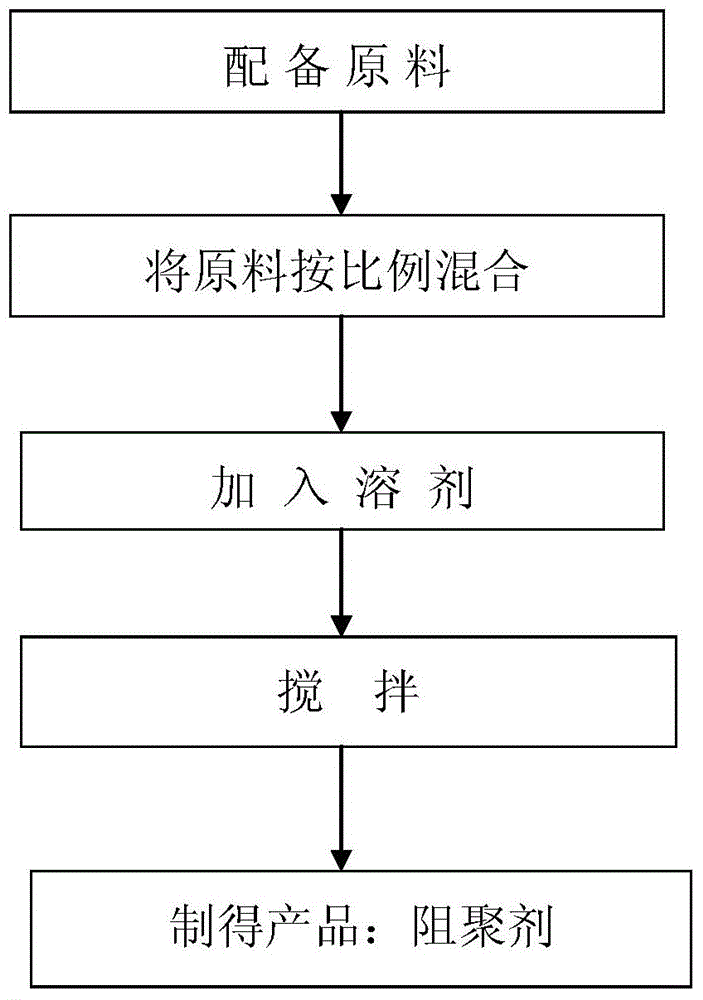

[0067] Preparation of inhibitors:

[0068] The mass proportioning of each component of polymerization inhibitor is as follows:

[0069] Hydroquinone: 94%;

[0070] Chlorpromazine: 4.5%;

[0071] Promethazine: 1.5%.

[0072] Mix hydroquinone, chlorpromazine and promethazine in the above ratio at normal temperature;

[0073] After mixing evenly, add it to the polymerization inhibitor tank configuration kettle, add the solvent toluene, stir and dissolve with a mixer;

[0074] Then the mixer is stopped, and the polymerization inhibitor configured is left in the polymerization inhibitor tank for use.

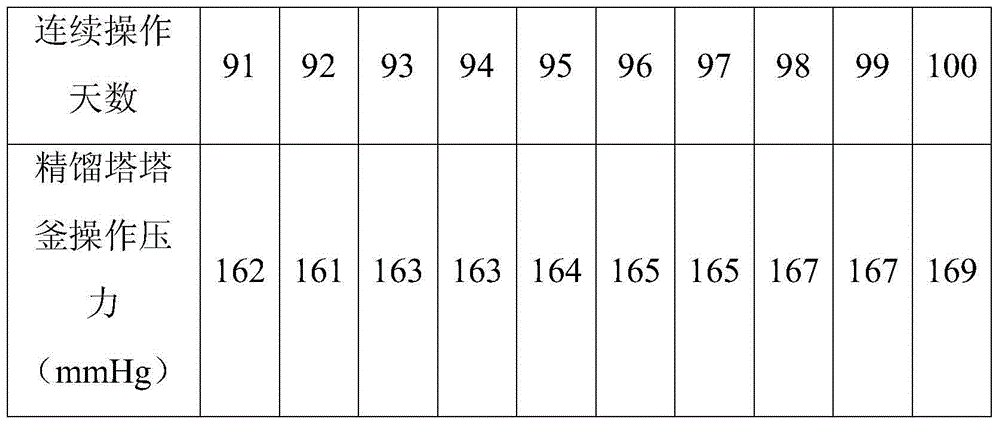

[0075] The reaction temperature of the rectification column and tower kettle is 87°C, the absolute pressure is 0.018MPa, under the condition that the mass ratio of crude acrylic acid and polymerization inhibitor is 1000:1, on the basis of re-starting the device after maintenance, the above-mentioned polymerization inhibitor is used For 100 days of continuous operation of the acr...

Embodiment 2

[0082] Preparation of inhibitors:

[0083] The mass proportioning of each component of polymerization inhibitor is as follows:

[0084] Hydroquinone: 94%;

[0085] Chlorpromazine: 4.5%;

[0086] Promethazine: 1.5%.

[0087] Mix hydroquinone, chlorpromazine and promethazine in the above ratio at normal temperature;

[0088] After mixing evenly, add it to the polymerization inhibitor tank configuration kettle, add the solvent toluene, stir and dissolve with a mixer;

[0089] Then the mixer is stopped, and the polymerization inhibitor configured is left in the polymerization inhibitor tank for use.

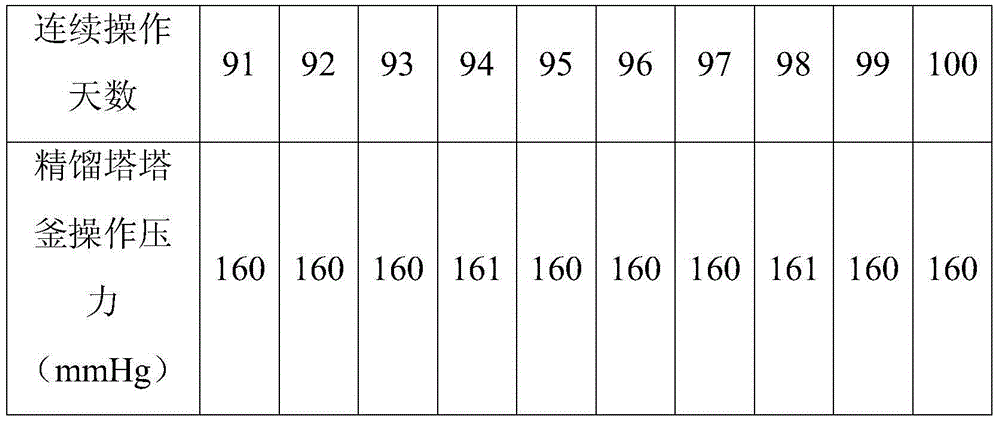

[0090] The reaction temperature of the rectification column and tower kettle is 87°C, the absolute pressure is 0.018MPa, under the condition that the mass ratio of crude acrylic acid and polymerization inhibitor is 1000:1, on the basis of re-starting the device after maintenance, the above-mentioned polymerization inhibitor is used For 100 days of continuous operation of the acr...

Embodiment 3

[0098] Preparation of inhibitors:

[0099] The mass proportioning of each component of polymerization inhibitor is as follows:

[0100] Hydroquinone: 95%;

[0101] Chlorpromazine: 4.0%;

[0102] Promethazine: 1.0%.

[0103] Mix hydroquinone, chlorpromazine and promethazine in the above ratio at normal temperature;

[0104] After mixing evenly, add it to the polymerization inhibitor tank configuration kettle, add the solvent toluene, stir and dissolve with a mixer;

[0105] Then the mixer is stopped, and the polymerization inhibitor configured is left in the polymerization inhibitor tank for use.

[0106] The reaction temperature of the rectification column and tower kettle is 85°C, and the absolute pressure is 0.015MPa. Under the condition that the mass ratio of crude acrylic acid and polymerization inhibitor is 1200:1, the above-mentioned polymerization inhibitor is used on the basis of re-starting the device after maintenance. For 100 days of continuous operation of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com