Method for extracting pine-seed oil

A technology of pine nut oil and pine nuts, which is applied in the field of edible vegetable oil extraction, can solve the problems of little research on the extraction of pine nut oil, and achieve the effects of low cost, simple equipment and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

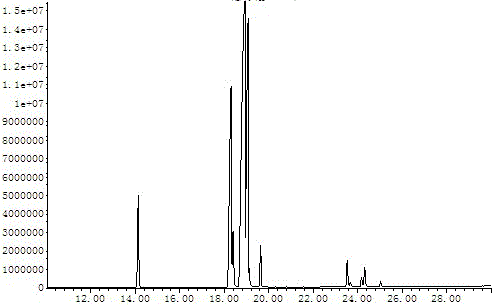

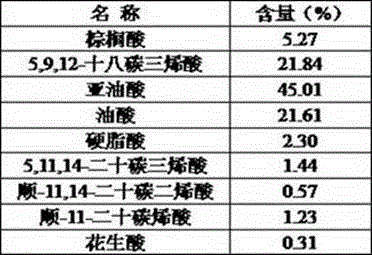

Image

Examples

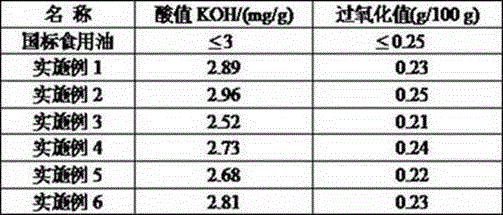

Embodiment 1

[0021] Clean the pine nuts, remove the shells and dry the pine nut kernels at a constant temperature until the quality is constant, crush them through a 60-mesh sieve, weigh 50g of pine nut kernel powder and place it in a reaction vessel. Pretreatment was carried out under the conditions of ℃ and 20 minutes; after the pretreatment, 2.5% cellulase was added, and the enzymatic hydrolysis and extraction was carried out for 3.0 hours under the conditions of temperature 45 ℃ and pH 4.0. After enzymatic hydrolysis, inactivate the enzyme in a boiling water bath for 10 minutes, then separate by centrifugation (centrifugal speed 3000r / min, 20min), take the free oil in the upper layer, and calculate the oil extraction rate, the extraction rate is 55.22%. (Note: The fat content of pine nuts is 58.12%, the same below).

Embodiment 2

[0023] Clean the pine nuts, remove the shells and dry the pine nut kernels at a constant temperature until the quality is constant, crush them through an 80-mesh sieve, weigh 50g of pine nut kernel powder and place it in a reaction vessel. Pretreatment was carried out under the conditions of 15min at ℃ and 15min; after the pretreatment, 2.0% cellulase was added, and enzymolysis and extraction were carried out at 45℃ and pH4.5 for 2.5h. After enzymatic hydrolysis, inactivate the enzyme in a boiling water bath for 10 minutes, and separate by centrifugation (centrifugal speed 3000r / min, 20min), take the free oil in the upper layer, and calculate the oil extraction rate, the extraction rate is 54.09%.

Embodiment 3

[0025] Clean the pine nuts, remove the shells and dry the pine nut kernels at a constant temperature until the quality is constant, crush them through an 80-mesh sieve, weigh 50g of pine nut kernel powder and place it in a reaction vessel. Pretreatment was carried out under the conditions of ℃ and 10 min; after the pretreatment, 2.0% cellulase was added, and the enzymatic hydrolysis and extraction was performed for 2.5 h at a temperature of 40 °C and a pH of 4.5. After enzymatic hydrolysis, inactivate the enzyme in a boiling water bath for 10 minutes, and separate by centrifugation (centrifugal speed 3500r / min, 20 minutes), take the free oil in the upper layer, and calculate the oil extraction rate, the extraction rate is 52.34%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com