Intensified permanent support assembly type basement structure system and construction method

A permanent support and basement technology, applied to underwater structures, infrastructure engineering, excavation, etc., can solve problems such as ineffective use of foundation pit support systems, waste of building materials and social resources, complex basement construction, etc., to achieve The effect of slope deformation control is good, the on-site construction is convenient and fast, and the effect of increasing the overall stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

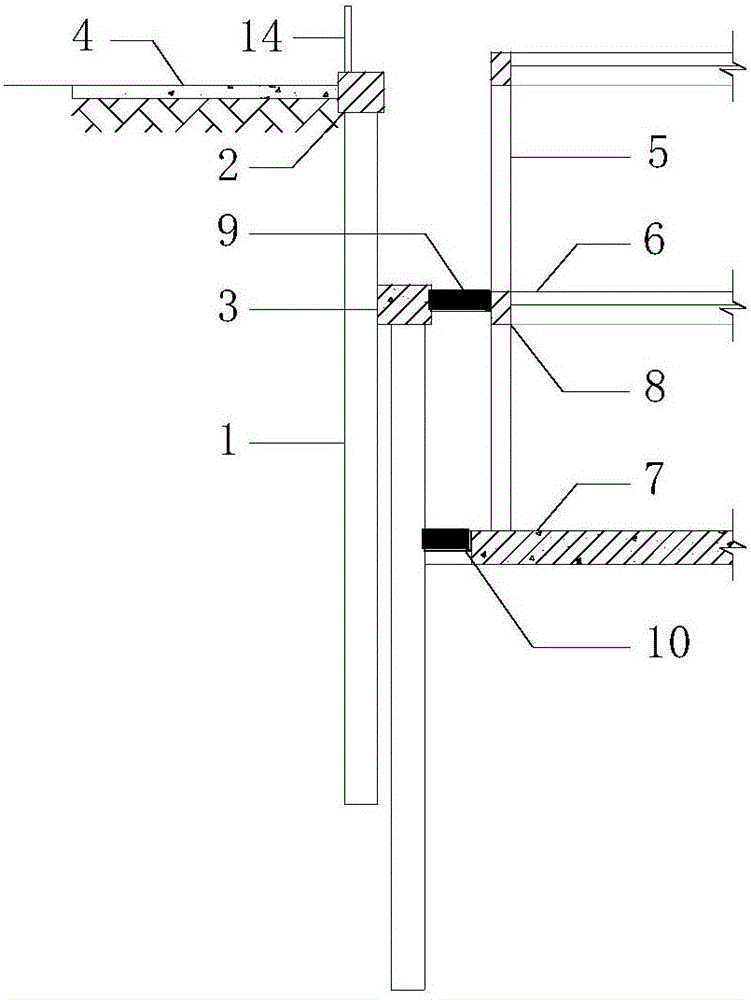

[0044] Such as figure 1 As shown, the underground structure of this project example is a two-story basement, and the underground structure includes prefabricated basement exterior wall 5, basement floor slab 6, basement floor slab 7, basement exterior wall beam 8 and other main components.

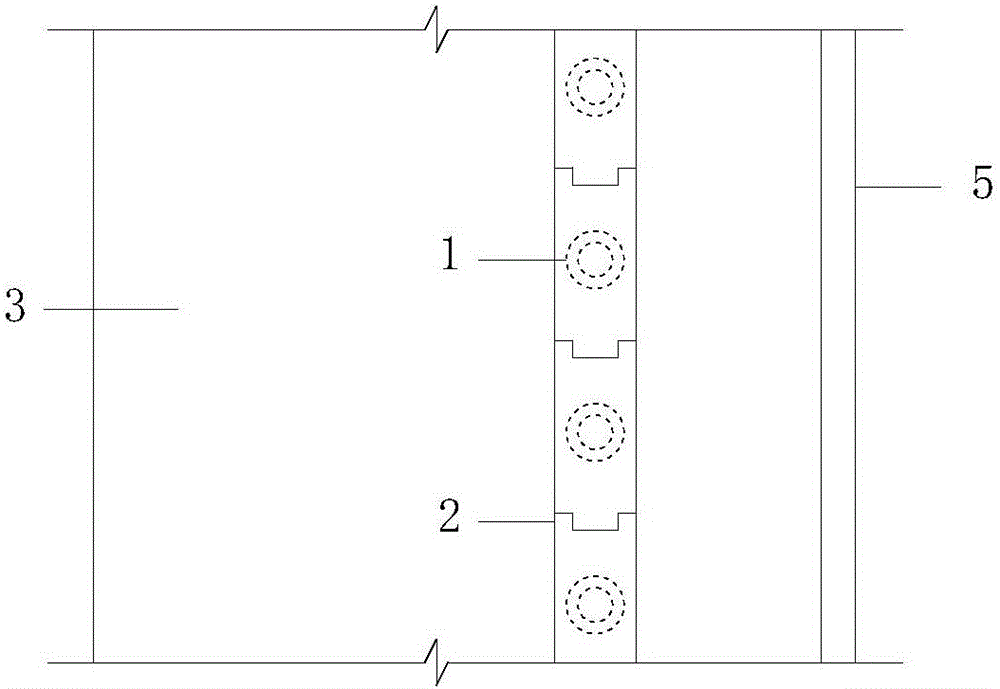

[0045] figure 1 As shown, the foundation pit support structure of this project example is a double-row prestressed pipe pile stepped support structure, which mainly includes support piles 1, prefabricated crown beams 2, and cast-in-place crown beams 3 and other main components.

[0046] figure 1 As shown, the first row of supporting piles in this project example is prestressed pipe piles, and the pile top crown beam 2 is connected with the concrete construction road 4 outside the foundation pit. The concrete construction road 4 outside the foundation pit is a concrete cast-in-place structure. The steel bars are connected to the crown and beam of the outer support piles; the top of the fi...

Embodiment 2

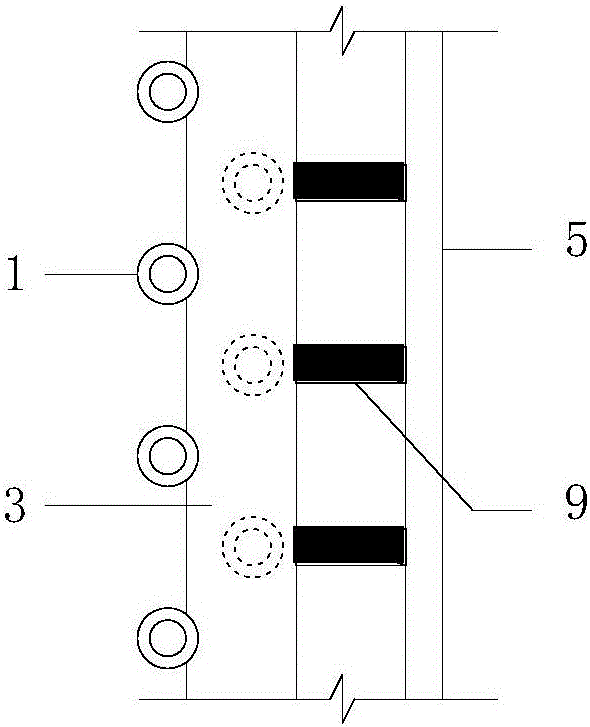

[0066] The difference between this embodiment and embodiment 1 is:

[0067] The first outrigger support is a reinforced concrete prefabricated support. One end of the outrigger support is connected to the pile body or waist beam of the support pile 1 through the embedded parts, and the other end is connected to the basement outdoor wall floor 6 through the embedded parts. The support connects the support piles with the basement structure. The support piles function as permanent components for a long time, which can effectively reduce the earth pressure on the basement exterior walls and reduce the thickness of the basement exterior walls.

Embodiment 3

[0069] Such as Figure 7 As shown, the underground structure of this engineering example is a three-story basement, and its specific structure and construction process are similar to those in Example 1. and the basement floor slab 6 are all prefabricated slabs, and the basement beam and column components are all concrete cast-in-place components.

[0070] Compared with Example 1, the difference of Example 3 is that the underground structure is a three-story basement, and there are three supports between the supporting structure and the outer wall of the basement. The outrigger 10 is still plain concrete support, and the outrigger 9 of the main structure of the last two floors is a reinforced concrete prefabricated support.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com