Waste heat comprehensive utilization system for fluidized bed

A technology of fluidized bed and waste heat, which is applied in the field of waste heat recovery system of fluidized bed, which can solve the problems of no secondary use of flue gas and slag waste heat, no secondary combustion of smoke and dust, etc., so as to improve the efficiency of fluidization reaction and extend the service life lifespan and avoid overheating damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

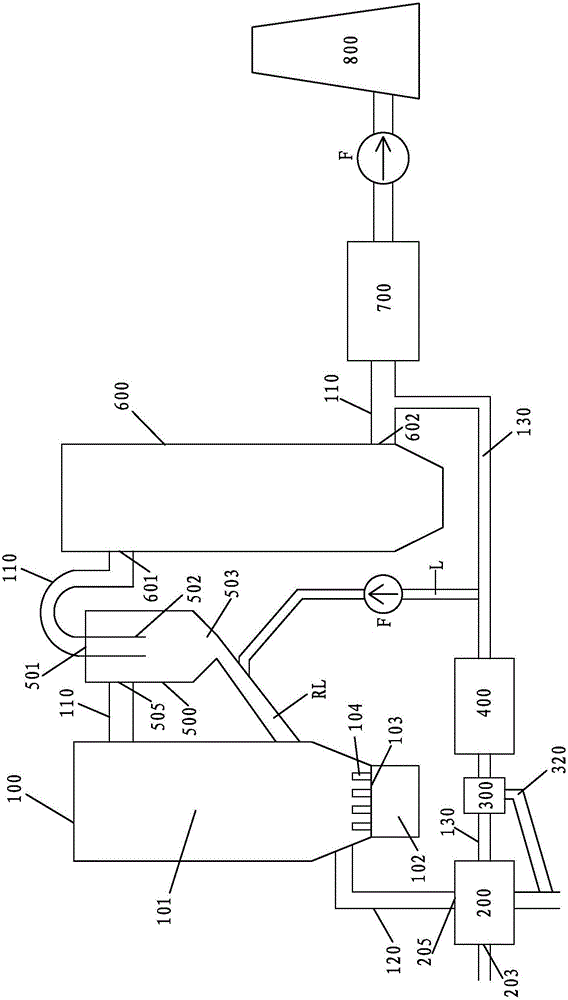

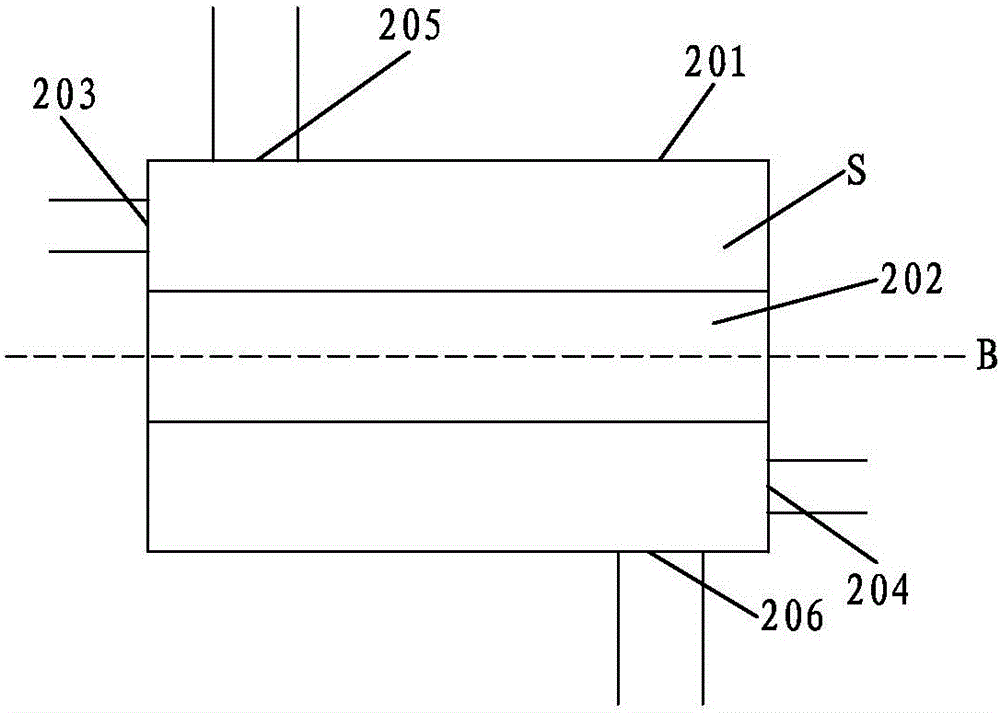

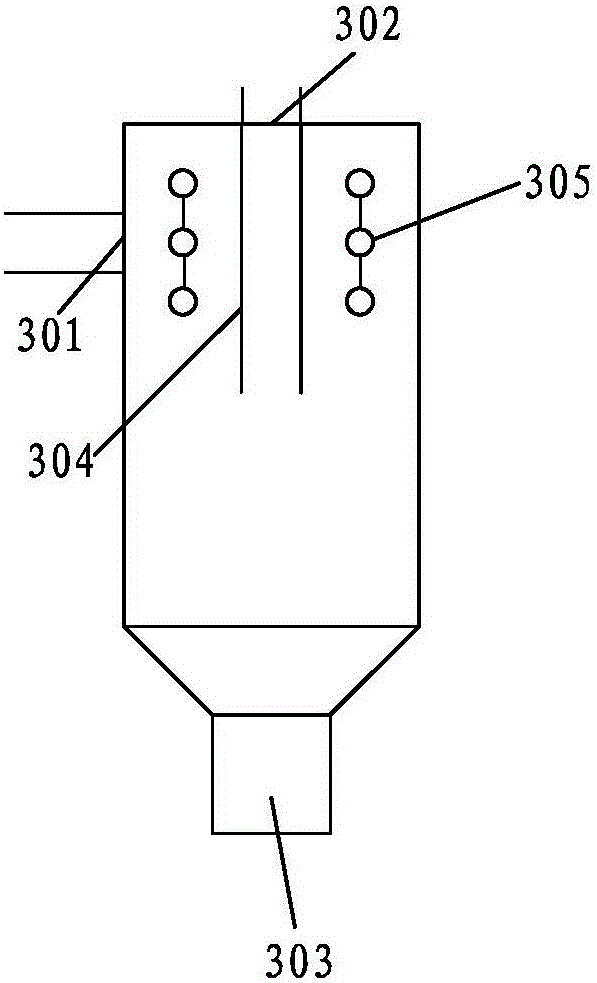

[0041] Please refer to figure 1 According to a non-limiting embodiment of the present invention, the fluidized bed waste heat comprehensive utilization system of the present invention includes: a fluidized bed 100, a flue gas pipeline 110, a slag discharge pipeline 120, a slag cooler 200, a water-cooled dust removal device 300, waste heat boiler 400 , soot separator 500 and heat exchanger 600 .

[0042] Wherein, the fluidized bed 100 includes a fluidized bed body (not labeled), and is arranged inside the fluidized bed body and divides the inside of the fluidized bed body into a fluidization chamber 101 located in the middle and upper part and an air distribution chamber 102 located in the lower part. The plate 103 and several air caps 104 arranged on the air distribution plate 103 are used to inject the fluidizing air into the fluidizing chamber 101 .

[0043] The flue gas pipe 110 is connected to the upper part of the side wall of the fluidized bed 100 to discharge the high ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com