Mouse presser foot height detection device and detection method thereof

A technology of height detection device and pressing angle, which is applied in measurement devices, optical devices, instruments, etc., can solve the problems of defective products flowing into customers, major customer complaints from end customers, affecting the feel of buttons, etc., so as to improve the defective detection rate. , avoid inflow to the client, improve the effect of delivery quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

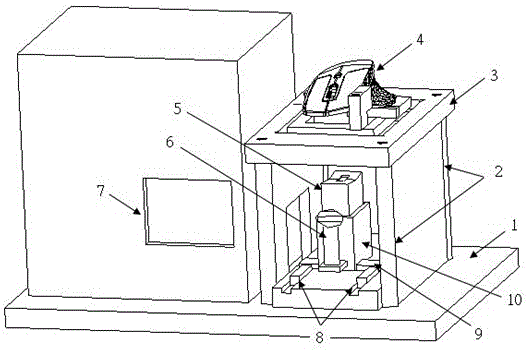

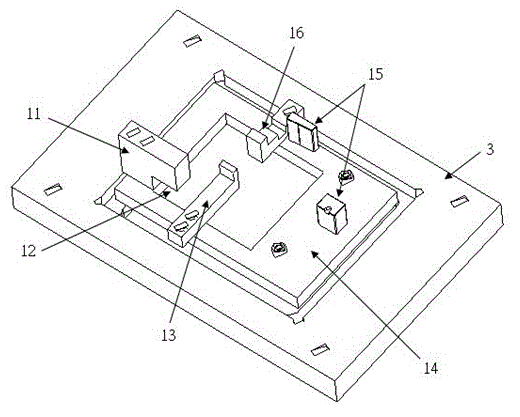

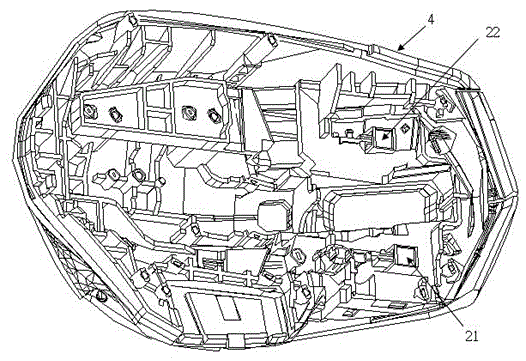

[0013] figure 1 It is a schematic diagram of the general assembly of the present invention, figure 2 It is a schematic diagram of the product positioning fixture, image 3 It is a schematic diagram of the measurement position of the product to be tested. The mouse button presser foot height detection device of the present invention includes: a horizontal adjustment table 1, an upper jig fixing rod 2, a product positioning jig 3, a non-contact depth gauge 5, a handle 6, a data display screen 7, and a left and right limit chute 8 , Lower jig positioning chute 9, non-contact depth gauge fixing jig 10, measurement reference block 11, measurement reference surface 12, left limit block 13, right limit block 16, product positioning level block 14, product Positioning column 15.

[0014] Fix the non-contact depth gauge 5 on the non-contact depth gauge fixing jig 10, fix the fixing jig 10 on the positioning chute 9 of the lower jig, and set the limit on the left and right sides of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com