Manufacturing method of low-cost sandstone artificial rock core for experimental teaching

An artificial core, low-cost technology, applied in the field of petroleum engineering, can solve the problems of large difference, limited source of raw materials, poor repeatability of core production, and achieves simple and easy operation, high repeatability and success rate, and simple and easy preparation method. effect of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0029] The sandstone artificial rock core that the present invention relates to comprises the following components, wherein each component is calculated by mass percentage,

[0030] Portland cement 57%;

[0031] Ordinary quartz sand 28%;

[0032] Distilled water: 15%;

[0033] A method for preparing a sandstone artificial core, comprising the steps of:

[0034] Quartz sand screened with a 60-mesh standard sieve is used as the rock skeleton, and it is evenly mixed with cement and distilled water;

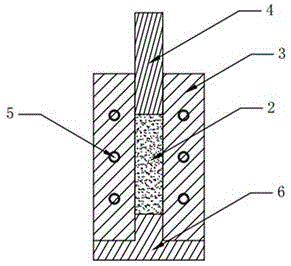

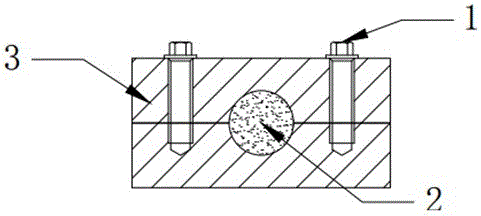

[0035] Put the mixture into the mold, apply a pressure above 23MPa for 24 hours, so that the cement, sand, and water are fully cemented; take out the rock sample and place it in a high-temperature drying oven at 108°C for 4 to 6 hours;

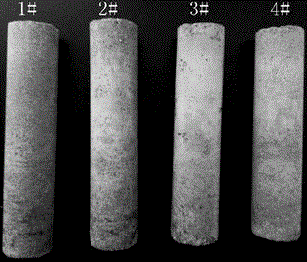

[0036] Take out the dry sample and cut it into a standard test sample (Φ25×100mm);

[0037] The manufactured artificial cores were used for experimental tests of different physical properties.

Embodiment example 2

[0039] The artificial sandstone core of the present invention comprises the following components, wherein each component is calculated by mass percentage,

[0040] Portland cement 57%;

[0041] Ordinary quartz sand 28%;

[0042] Distilled water: 15%;

[0043] A method for preparing a sandstone artificial core, comprising the steps of:

[0044] Quartz sand screened with a 40-mesh standard sieve is used as the rock skeleton, and it is evenly mixed with cement and distilled water;

[0045] Put the mixture into the mold, apply a pressure above 23MPa for 24 hours, so that the cement, sand, and water are fully cemented; take out the rock sample and place it in a high-temperature drying oven at 108°C for 4 to 6 hours;

[0046] Take out the dry sample and cut it into a standard test sample (Φ25×100mm);

[0047] The manufactured artificial cores were used for experimental tests of different physical properties.

Embodiment example 3

[0049] The artificial sandstone core of the present invention comprises the following components, wherein each component is calculated by mass percentage,

[0050] Portland cement 57%;

[0051] Ordinary quartz sand 28%;

[0052] Distilled water: 15%;

[0053] A method for preparing a sandstone artificial core, comprising the steps of:

[0054] Quartz sand screened with a 20-mesh standard sieve is used as the rock skeleton, and it is evenly mixed with cement and distilled water;

[0055] Put the mixture into the mold, apply a pressure above 23MPa for 24 hours, so that the cement, sand, and water are fully cemented; take out the rock sample and place it in a high-temperature drying oven at 108°C for 4 to 6 hours;

[0056] Take out the dry sample and cut it into a standard test sample (Φ25×100mm);

[0057] The manufactured artificial cores were used for experimental tests of different physical properties.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com