Rock tri-axial test crack extension observation device based on electrical capacitance tomography technique

A technology of electric capacitance tomography and triaxial test, which is applied in the direction of measuring device, using stable tension/pressure to test the strength of materials, analyzing materials, etc., can solve the problem of remaking the triaxial chamber, which is time-consuming and laborious, and the CT scanner is expensive and other problems, to achieve the effect of low price, simple device structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

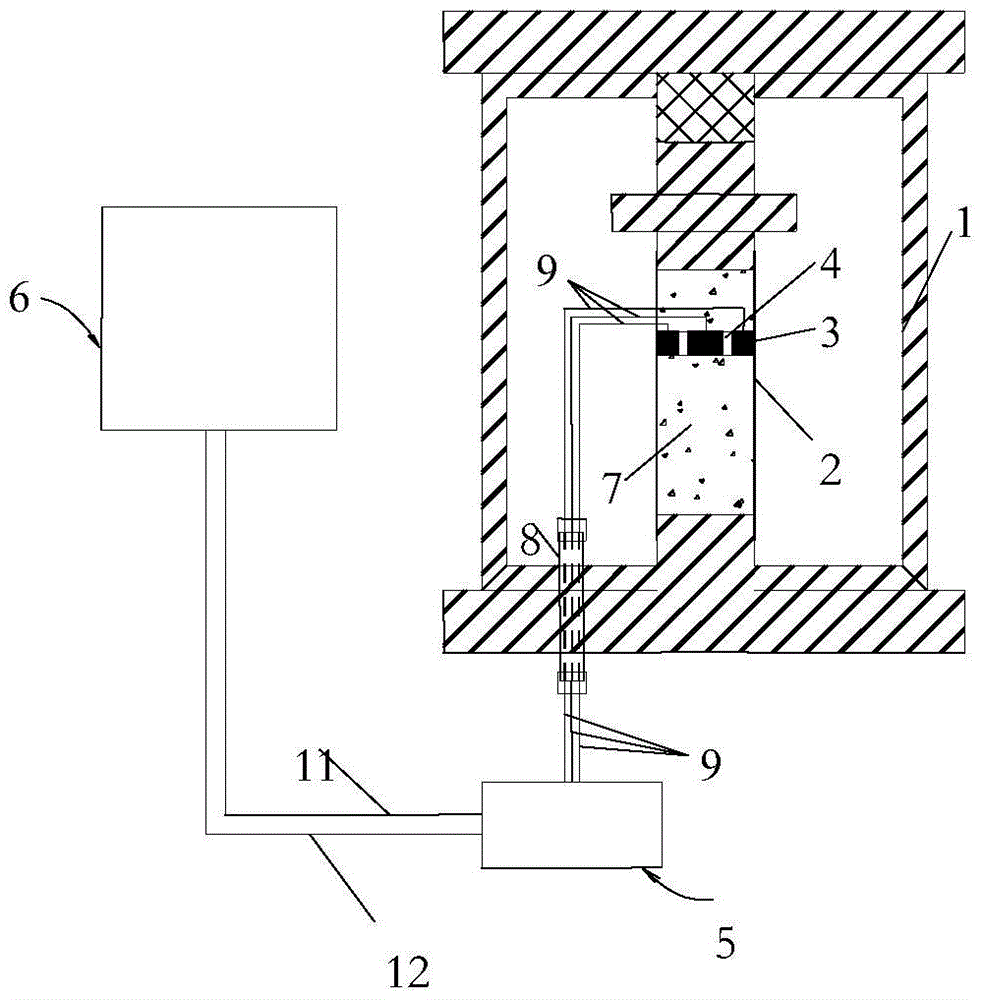

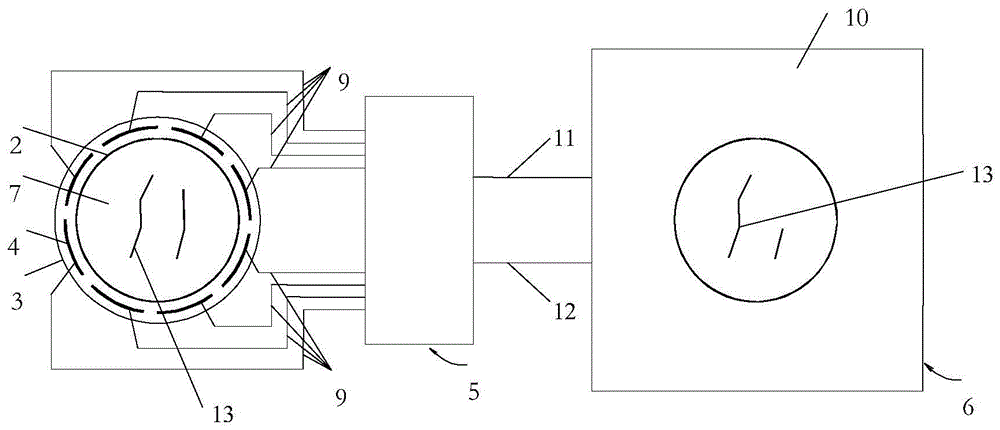

[0035] Taking marble as an example, the device of the present invention is used to observe the expansion of cracks in the rock sample, and the usage method is as follows:

[0036] 1. Take the marble rock specimen, the specimen is a cylindrical standard specimen, wrap the rubber sleeve 2 on the outside of the specimen, and then hoop the double-layer rubber ring 3 on the outside of the rubber sleeve 2, and the two layers of the double-layer rubber ring 3 There are 8 annular electrodes 4 distributed at equal intervals between them;

[0037] 2. Place the marble sample on the rigid indenter of the triaxial chamber 1, then place the rigid upper indenter on the top, and fasten the rubber sleeve 2 with a hoop, so that the hydraulic oil cannot enter the rubber sleeve 2 when the confining pressure is loaded. Inside;

[0038] 3. Connect the cable 9 and the connector male head between the ring electrode 4 and the data acquisition module 5 to the female head of the multi-hole cable wiring...

Embodiment 2

[0042] Taking high-porosity sandstone rock as an example, the device of the present invention is used to observe the expansion of cracks in the rock sample, and the use method is as follows:

[0043] 1. Take a standard high-porosity sandstone rock sample, as in steps 1 to 3 of Example 1, and verify the device;

[0044] 2. Install the seepage pipeline for rock seepage test, so that the triaxial test device can carry out long-term rheological test under seepage;

[0045] 3. Close the triaxial chamber 1, start the confining pressure oil pump to fill the triaxial chamber 1 with oil, and apply the confining pressure to the predetermined value;

[0046] 4. Start the water pump of the triaxial rheometer to adjust the osmotic pressure acting on the upper and lower ends of the sandstone sample, so that the infiltrated water can slowly saturate the sandstone sample under the pressure of the water pump and penetrate the rock sample;

[0047] 5. Start the axial pressure oil pump, gradual...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com