Method for quickly measuring heat conductivity coefficient of semiconductor film

A thermal conductivity, semiconductor technology, applied in the field of microelectronics, can solve the problem of no fast and accurate measurement method and difficult measurement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

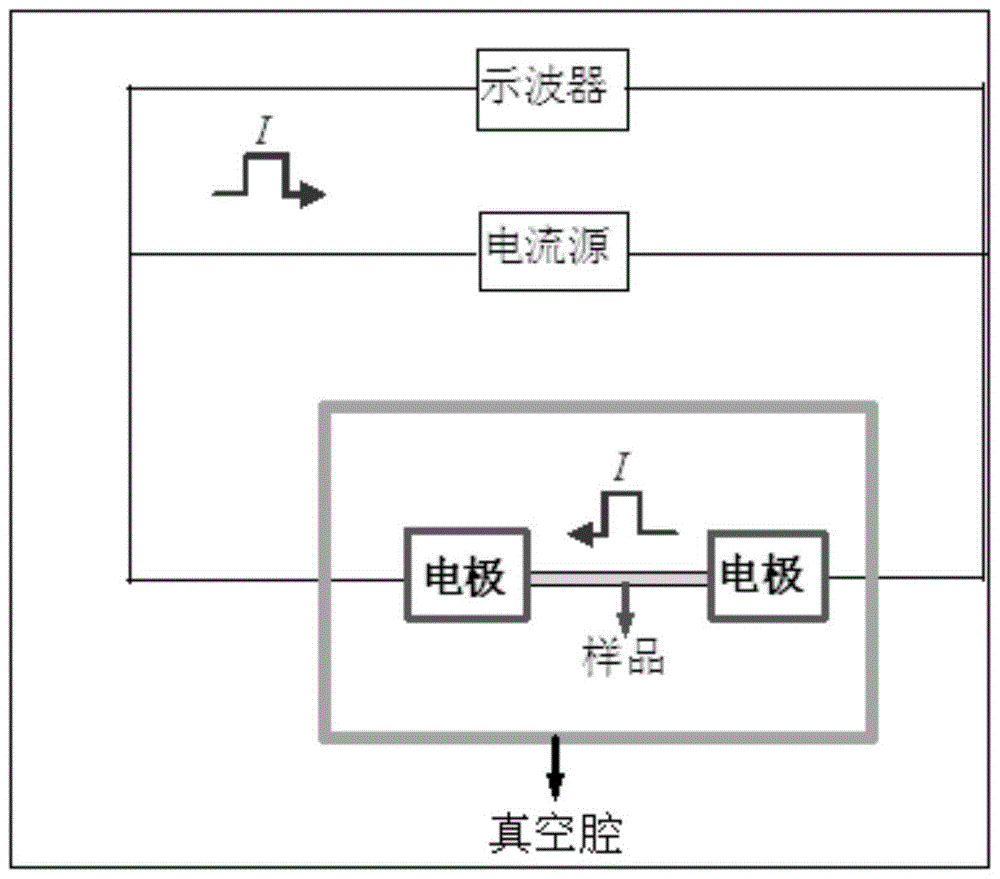

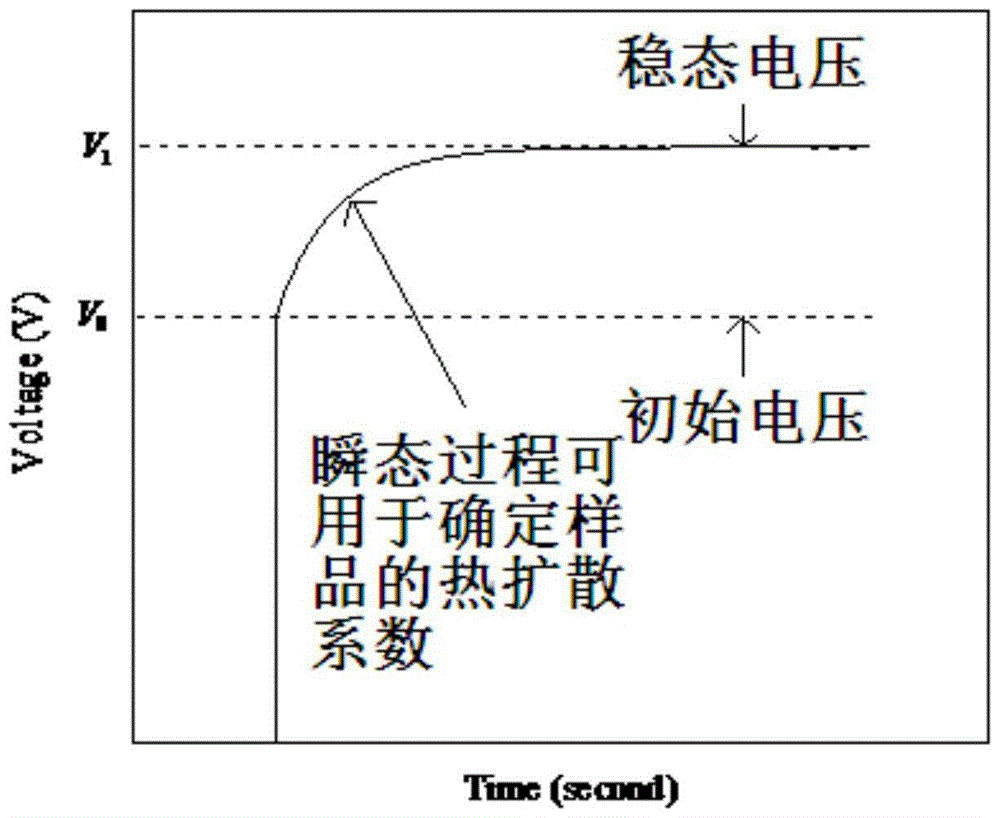

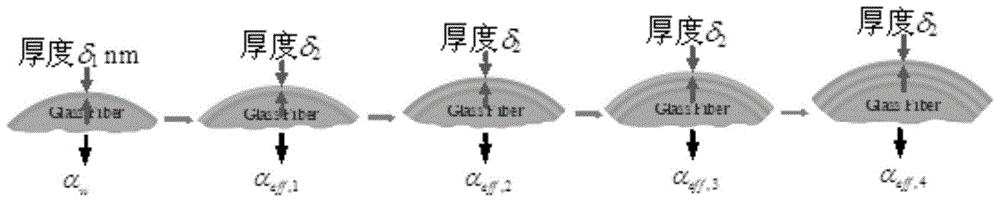

[0048] refer to figure 1 , 2 , 3, a method for quickly measuring the thermal conductivity of a semiconductor thin film in this embodiment,

[0049] Firstly, a glass fiber with a length of 559 μm and a diameter of 9 μm is selected as the base material and coated with a gold film with a thickness of 10 nm as the base material, and the thermal diffusivity α of the base material is calculated by transient electrothermal technology w 6.95×10 -7 m 2 ·s -1 . Then sputter 4 times of zinc oxide films with a thickness of 60nm on the base material to form 4 samples, and calculate the thermal diffusivity α of the 4 samples by transient electrothermal technology under the same environmental conditions eff,1 is 7.06×10 -7 m 2 ·s -1 、α eff,2 7.15×10 -7 m 2 ·s -1 、α eff,3 is 7.29×10 -7 m 2 ·s -1 、α eff,4 7.36×10 -7 m 2 ·s -1 , for 4 sets of α eff Perform linear fitting to obtain a slope of 1.04×10 -8 m 2 ·s -1 ,

[0050] The slope=4δ 2 [k c -α w (ρc p ) c ] / πD(ρc...

Embodiment 2

[0053] A method for quickly measuring the surface thermal conductivity of a semiconductor thin film in this embodiment,

[0054] Firstly, a glass fiber with a length of 594 μm and a diameter of 9.17 μm is selected as the base material and coated with a layer of gold film with a thickness of 10 nm as the base material, and the thermal diffusivity α of the base material is calculated by transient electrothermal technology w is 7.06×10 -7 m 2 ·s -1 . Then sputtering 4 times of zinc oxide films with a thickness of 40nm on the base material to form 4 samples, and under the same environmental conditions, the thermal diffusivity α of the 4 samples was calculated by transient electrothermal technology. eff,1 7.11×10 - 7 m 2 ·s -1 、α eff,2 7.17×10 -7 m 2 ·s -1 、α eff,3 7.20×10 -7 m 2 ·s -1 、α eff,4 7.25×10 -7 m 2 ·s -1 , for 4 sets of α eff Perform linear fitting to obtain a slope of 4.52×10 -9 m 2 ·s -1 ,

[0055] The slope=4δ 2 [k c -α w (ρc p ) c ] / πD(ρc...

Embodiment 3

[0058] A method for quickly measuring the surface thermal conductivity of a semiconductor thin film in this embodiment,

[0059] First, select a piece of glass fiber with a length of 482 μm and a diameter of 9.73 μm as the base material and plate a layer of gold film with a thickness of 10 nm as the base material, and calculate the thermal diffusivity α of the base material through transient electrothermal technology w 6.64×10 -7 m 2 ·s -1 . Then sputter 4 zinc oxide films with a thickness of 20nm on the base material to form 4 samples, and calculate the thermal diffusivity α of the 4 samples by transient electrothermal technology under the same environmental conditions eff,1 6.66×10 - 7 m 2 ·s -1 、α eff,2 is 6.67×10 -7 m 2 ·s -1 、α eff,3 is 6.69×10 -7 m 2 ·s -1 、α eff,4 6.71×10 -7 m 2 ·s -1 , for 4 sets of α eff Perform linear fitting to obtain a slope of 1.75×10 -9 m 2 ·s -1 ,

[0060] The slope=4δ 2 [k c -α w (ρc p ) c ] / πD(ρc p ) w

[0061] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com