Windproof cover assembly of fiber welding machine

A technology of optical fiber fusion splicer and cover assembly, which is applied in the direction of optical components, optical waveguide coupling, lighting device components, etc., which can solve the problem of damage to the firmness and stability of the windproof cover and optical fiber fusion splicer, and limit the overall size of the optical fiber fusion splicer , affect the overall appearance of the fiber optic fusion splicer, etc., to achieve the effect of ensuring stability and effectiveness, simple and convenient structure, and simplified structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Next, the present invention will be further described through specific examples.

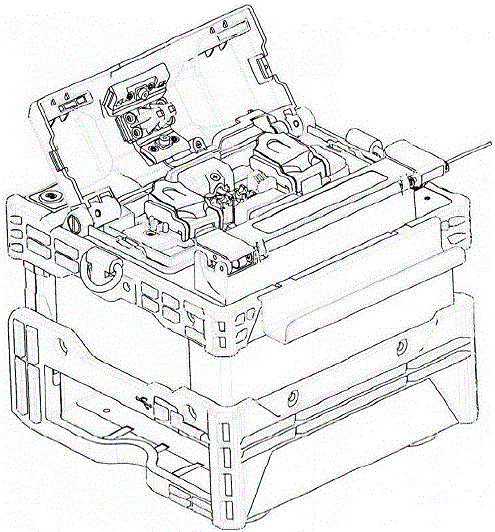

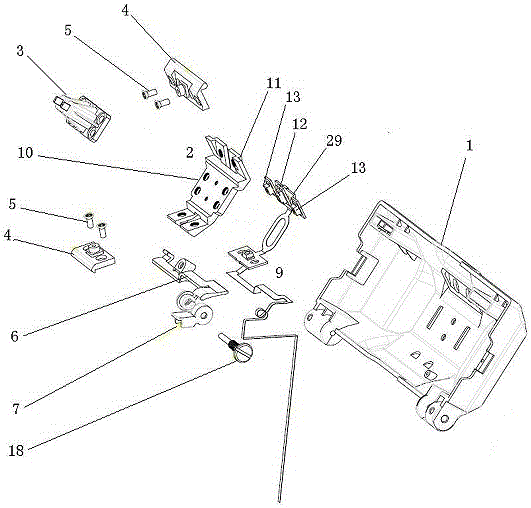

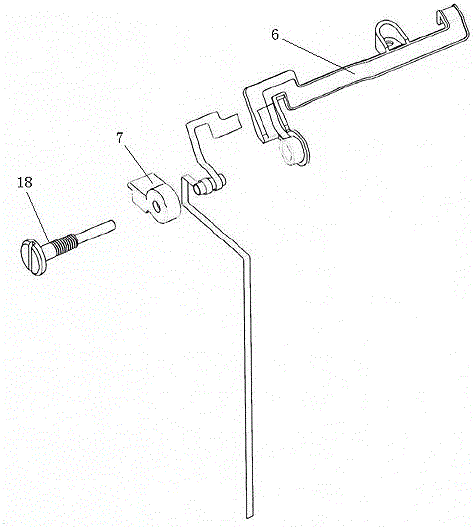

[0036] refer to Figure 1-9 , which shows a schematic view of the windshield assembly of the optical fiber fusion splicer of the present invention and its various components;

[0037] First, refer to Figure 1-2, the present invention provides a windproof cover assembly for an optical fiber fusion splicer, including a windproof cover 1, a mount assembly, an FPC component, and a windproof cover shaft 18, characterized in that: the windproof cover 1 includes a cover surface and an internal accommodation space. The inner accommodation space is provided with a white light lamp assembly for working lighting of the fusion splicer. The white light lamp assembly includes a white light lamp and an FPC line for powering it. The FPC line here can be borrowed from a red light FPC line (combined with the red light FPC line), or a separate white light power supply FPC can be set. line, the present i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com