Decoupling Compensation Control Method for Coordinated Control of Unit Generators and Main Control System

A unit unit, coordinated control technology, applied in general control systems, control/regulation systems, adaptive control, etc., can solve problems such as affecting the intake air volume of the steam turbine, affecting the main steam pressure of the boiler, and affecting the unit load.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0093] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

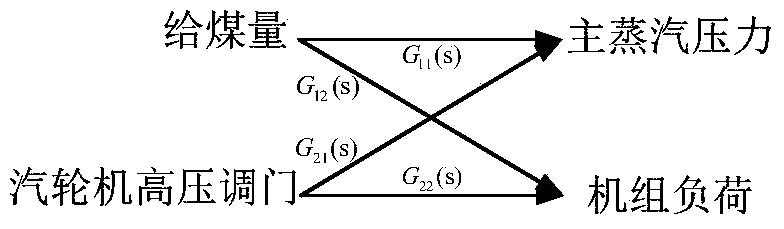

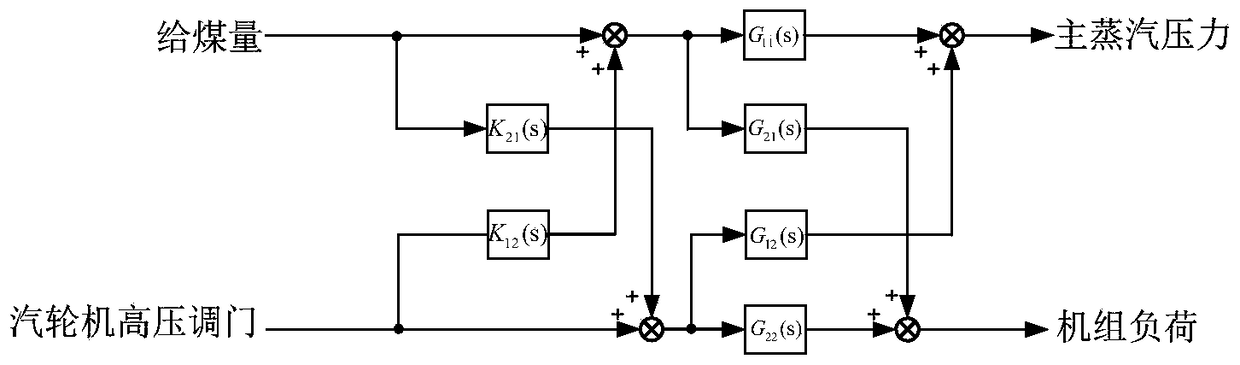

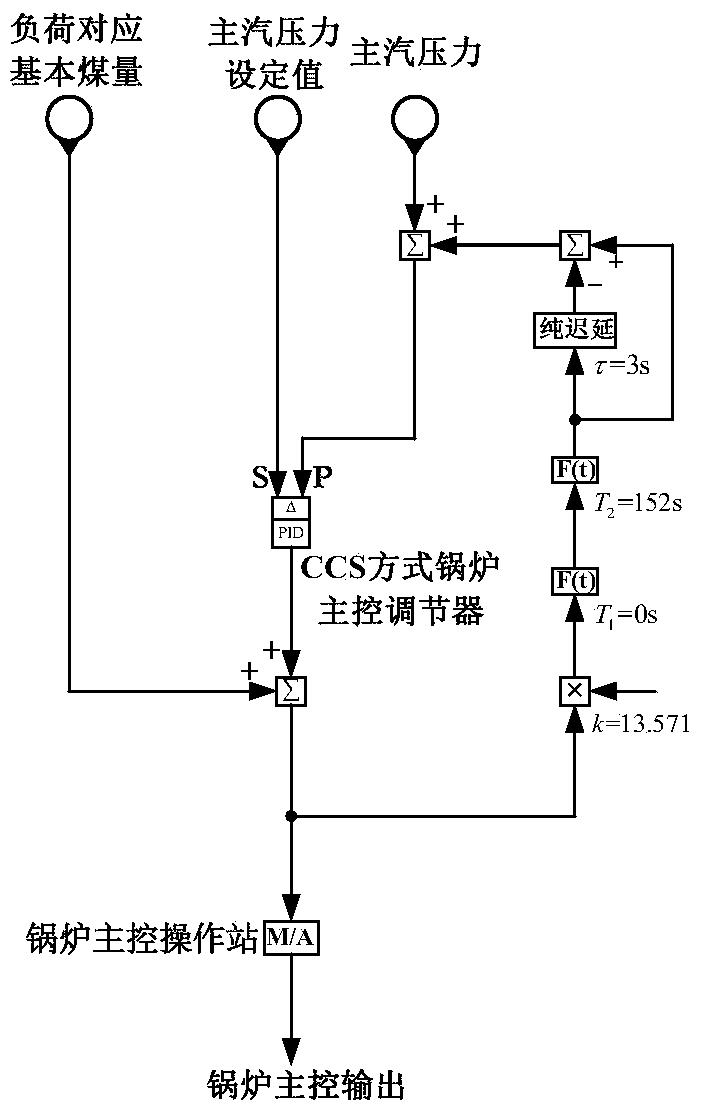

[0094] Such as Figure 1 to Figure 4 As shown, taking a 300MW subcritical drum boiler in China as an example, the decoupling compensation control method of the main control system of the coordinated control of the unit unit is explained as follows in conjunction with the simplified diagram. It is obtained through the disturbance test and the genetic identification algorithm,

[0095] 1) Transfer function G of coal feed relative to main steam pressure 11 (s) are as follows:

[0096]

[0097] Among them, k 11 Gain of main steam pressure relative to coal feed, T 11 Inertia time of main steam pressure relative to coal feed rate, τ 11 The delay time of the main steam pressure relative to the coal supply link, s is the Laplacian operator;

[0098] Get the transfer function G of the coal feed relative to the load of the unit 21 (s) are as follows:

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com