Control system and control method of intelligent vacuum degassing machine

A vacuum degassing and control method technology, applied in the field of degassing, can solve problems such as high energy consumption, inaccurate control, and wear of water pump cavitation bearings, so as to shorten the debugging time, eliminate pipe network noise, and improve heat exchange efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

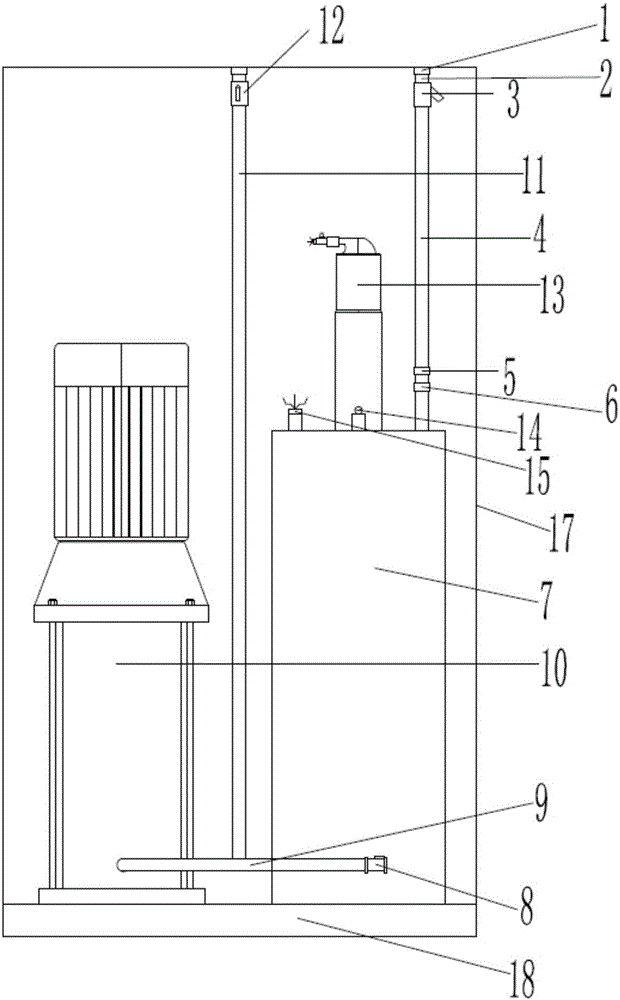

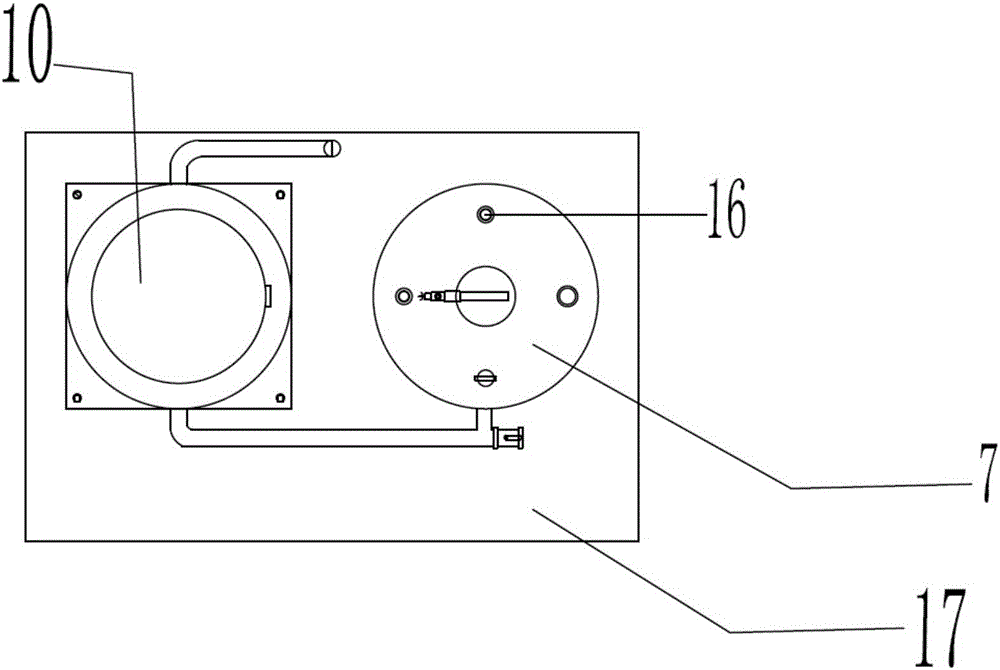

[0053] like Figures 1 to 5As shown, an intelligent vacuum degasser includes: a casing 17 and an increasing pump 10 and a degassing tank 7 inside the casing 17 . Both the booster pump 10 and the degassing tank 7 are located on the base 18 .

[0054] The shell 17 forms protection for internal equipment, such as a degassing tank, a booster pump, etc., which is beneficial to prolonging the service life of the equipment.

[0055] One side of the casing 17 is provided with a door that can be opened or closed for putting in equipment such as the pump 10 and the degassing tank 7. The inside of the casing 17 is provided with a controller, and the door of the casing 17 is provided with a touch screen , the touch screen is connected to the controller through a signal line. It is convenient to set various parameters through the touch screen.

[0056] The top of the degassing tank 7 is provided with a pressure sensor 15 , a pressure gauge 14 , a real-time online gas monitoring device 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com