Defoaming method of polyamide acid resin salivation liquid film and device thereof

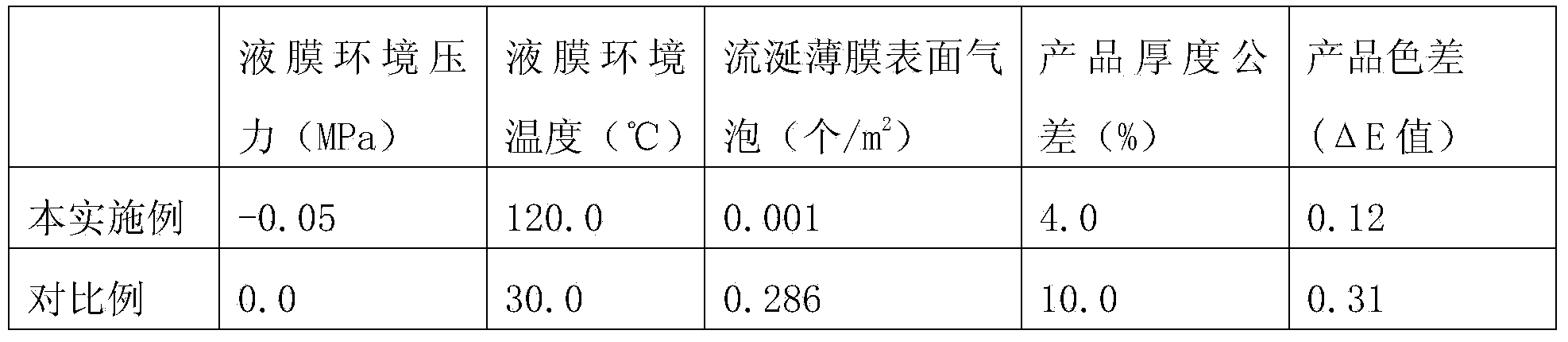

A technology of polyamic acid resin and defoaming device, which is applied in application, coating, household appliances, etc., can solve the problem that there is no effective defoaming method and device for polyamic acid resin salivating liquid film, and achieve defoaming process operation Convenience, improved thickness uniformity, and reduced chromatic aberration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

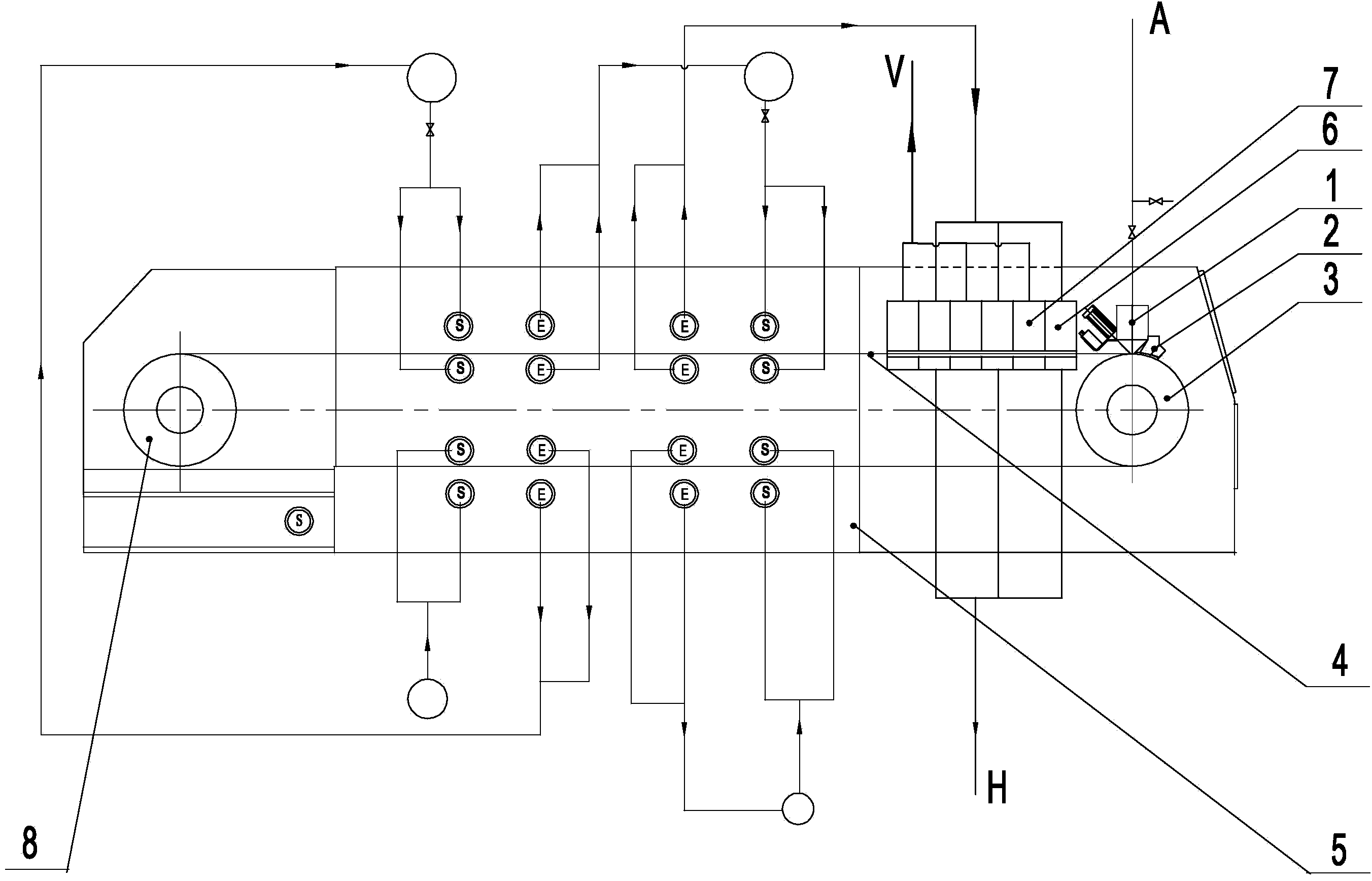

[0029] The embodiment of the defoaming device of this polyamic acid resin salivation film is for example figure 1 As shown, it comprises a polyamic acid resin solution extrusion die 1, a steel belt 4 and a drool oven 5, and the endless steel belt 4 circulates around the front drum 3 and the rear drum 8, and the lip of the extrusion die 1 is located opposite to The steel belt 4 at the highest point of the front drum 3 has three sets of high-temperature solvent gas boxes 6 and vacuum boxes 7 behind the extrusion die 1, and a front high-temperature solvent gas box 6 and a vacuum box 7 next to each other form a group , the steel strip 4 carrying the polyamic acid resin liquid film obtained by salivation passes through each group of high-temperature solvent gas boxes 6 and vacuum boxes 7 in sequence, and then enters the salivation oven 5 .

[0030] The high-temperature solvent gas box 6 is a closed box, with a steel strip inlet on the front end and a steel strip outlet on the rear ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com