A kind of preparation method of wheat ear shape te-pt alloy nanowire

A technology of alloy nano and wheat ear shape, which is applied in the field of preparation of Te-Pt alloy nanowires, can solve the problems of expensive use of precious metal platinum, high cost of fuel cell production, and influence on catalytic performance, and achieve good stability and smooth preparation process. Simple, easy-to-scale effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] A preparation method of ear-shaped Te-Pt alloy nanowires, comprising the following steps:

[0017] 1) Using a tellurium source to prepare tellurium nanowires, weigh 1 part of tellurium nanowires in parts by mass and add them to a beaker containing 25 parts of absolute ethanol, and magnetically stir for 30 minutes to make the dispersion uniform;

[0018] 2) Take the dispersed solution obtained in step 1), add the required platinum source in the ratio of tellurium to platinum atom molar ratio of 10:1, disperse into ultrapure water, put it into a polytetrafluoroethylene liner, and move it into the reaction kettle After hydrothermal reaction in medium for 4 hours, the finished product of wheat ear-shaped Te-Pt alloy nanowires is obtained.

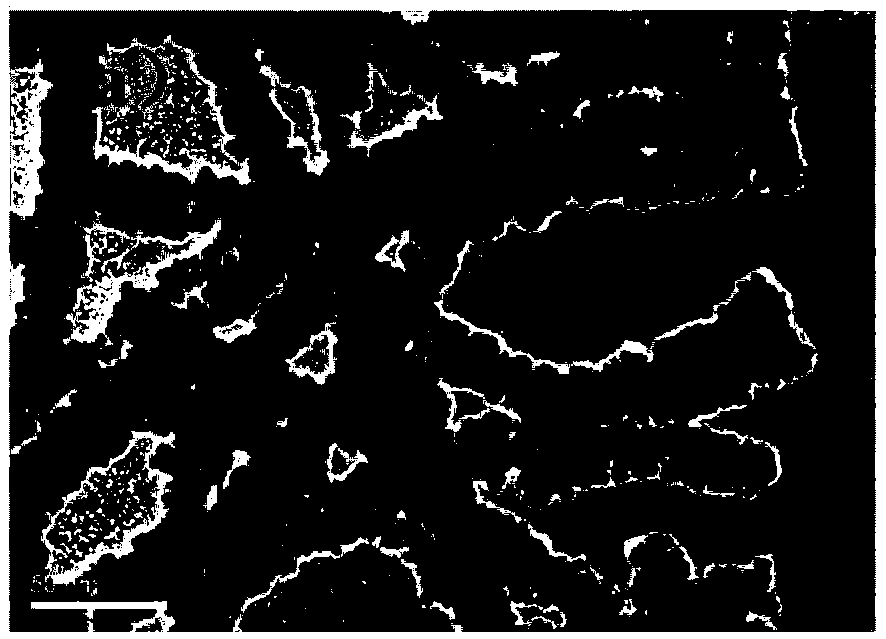

[0019] In this way, wheat ear-shaped tellurium-platinum alloy nanowires with a diameter of 25 nanometers can be prepared. In the microscopic state, tellurium-platinum alloy nanowires with a large aspect ratio are intertwined with each ot...

Embodiment 2

[0021] A preparation method of ear-shaped Te-Pt alloy nanowires, comprising the following steps:

[0022] 1) Using a tellurium source to prepare tellurium nanowires, weigh 3 parts of tellurium nanowires in parts by mass and add them to a beaker containing 35 parts of absolute ethanol, and magnetically stir for 40 minutes to make the dispersion uniform;

[0023] 2) Take the dispersion solution obtained in step 1), add the required platinum source in the ratio of tellurium to platinum atom molar ratio of 10:10, disperse into ultrapure water, put it into a polytetrafluoroethylene lining, and move it into the reaction kettle After 5 hours of hydrothermal reaction, the finished product of wheat ear-shaped Te-Pt alloy nanowires is obtained.

Embodiment 3

[0025] A preparation method of ear-shaped Te-Pt alloy nanowires, comprising the following steps:

[0026] 1) Using a tellurium source to prepare tellurium nanowires, weigh 5 parts of tellurium nanowires in parts by mass and add them to a beaker containing 50 parts of absolute ethanol, and magnetically stir for 50 minutes to make the dispersion uniform;

[0027] 2) Take the dispersion solution obtained in step 1), add the required platinum source in the ratio of tellurium to platinum atom molar ratio of 10:80, disperse into ultrapure water, put it into a polytetrafluoroethylene liner, and move it into the reaction kettle After 6 hours of hydrothermal reaction, the finished product of wheat ear-shaped Te-Pt alloy nanowires is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com