Graphite composite bipolar plate and fuel cell stack

A fuel cell stack and bipolar plate technology, which is applied to fuel cell grouping, fuel cell components, battery electrodes, etc., can solve problems such as infeasibility of battery systems, and achieve convenient implementation, low energy consumption, and improved cooling rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

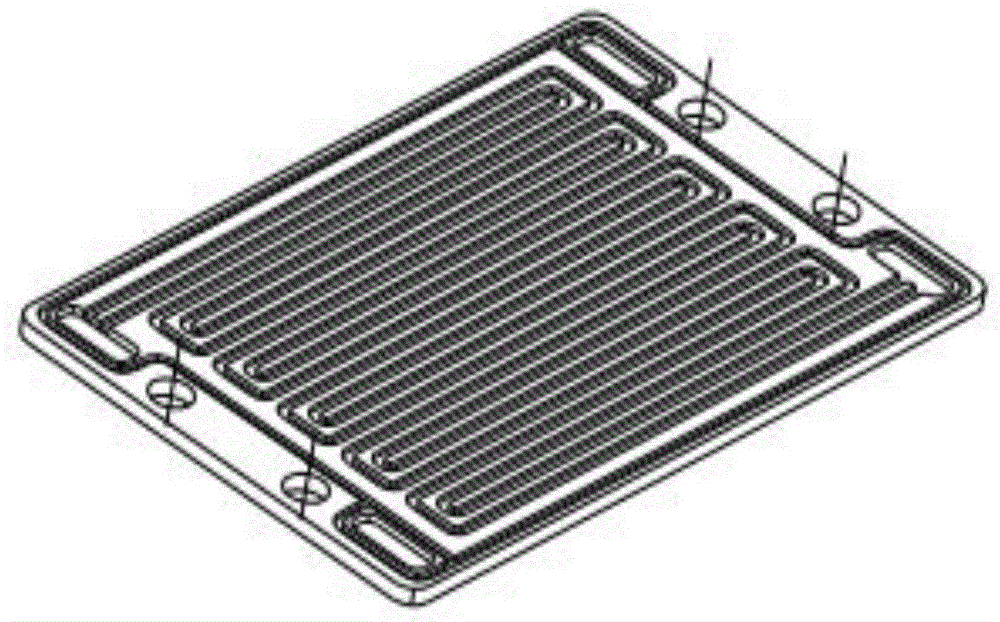

[0013] The graphite composite bipolar plate is pressed by mixing graphite powder, resin and metal aluminum powder, and the mass content of the metal aluminum powder is 5%. Serpentine flow fields are etched on both sides of the bipolar plate, and the size of the bipolar plate is 7.5cm×5cm.

[0014] The above five bipolar plates and five commercial membrane electrodes (JM) were stacked alternately in sequence, and end plates were assembled at both ends to form a fuel cell stack.

[0015] Stop the above-mentioned fuel cell stack under normal working conditions and transfer it to -20°C for cooling down. When the stack reaches the ambient temperature, test the water content in the membrane electrodes of the stack. According to the test results, the average water content in each membrane electrode is 9mg / cm 2 .

Embodiment 2

[0017] The graphite composite bipolar plate is pressed by mixing graphite powder, resin and metal copper powder, and the mass content of the metal copper powder is 5%. Serpentine flow fields are etched on both sides of the bipolar plate, and the size of the bipolar plate is 7.5cm×5cm.

[0018] The above five bipolar plates and five commercial membrane electrodes (JM) were stacked alternately in sequence, and end plates were assembled at both ends to form a fuel cell stack.

[0019] Stop the above-mentioned fuel cell stack under normal working conditions and transfer it to -10°C for cooling down. When the stack reaches ambient temperature, test the water content in the membrane electrodes of the stack. According to the test results, the average water content in each membrane electrode is 10mg / cm 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com