Preparation method for high-energy sodium-chloride intermediate-temperature thermal battery

A thermal battery, sodium chloride technology, applied in the direction of delayed action cells, etc., can solve the problems of chemical production battery pollution, uneven battery voltage, complex process, etc., to achieve the suppression of sodium dendrites, fast heating speed, production The effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

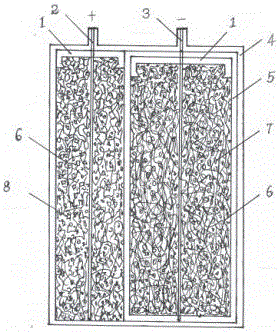

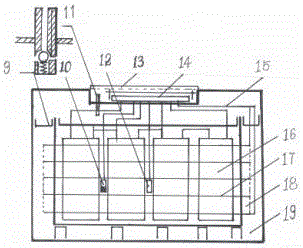

[0013] Example 1, such as figure 1 , figure 2 Shown, the present invention comprises stainless steel card 1, positive electrode 2, negative electrode 3, polyimide aramid fiber material 4, it is characterized in that: carry out according to the following steps

[0014] (1) Preparation of cathode material for sodium-chlorine thermal battery; first make NaAlCl 4 Medium temperature ionic liquid molten salt, the analytically pure AlCl 3 Place in a microwave mixer and heat to 170°C to form AlCl 3 Molten salt, add analytical pure NaCl at a molar ratio of 1:1, gradually heat and stir at a rate of 5°C per minute for 1 hour to 270°C--350°C, then mix analytically pure NaCl and gas phase at a molar ratio of NaCl:Ni=1:1 Deposit metallic Ni powder, by mixture with NaAlCl 4 Add the mass ratio of 4:1 into the microwave mixer and stir for 6 hours to prepare NaAlCl 4 , NaCl, and Ni melted and mixed medium-temperature colloid 8, impregnated and extruded low-density graphite felt 6 into the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com