Electron stopping device

A stopping device and electronic technology, applied in circuit devices, battery circuit devices, electric vehicles, etc., can solve the problems of inability to recover energy, low efficiency of the energy recovery system, and difficulty in controlling the stopping process of the braking device, and achieve excellent output characteristics. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

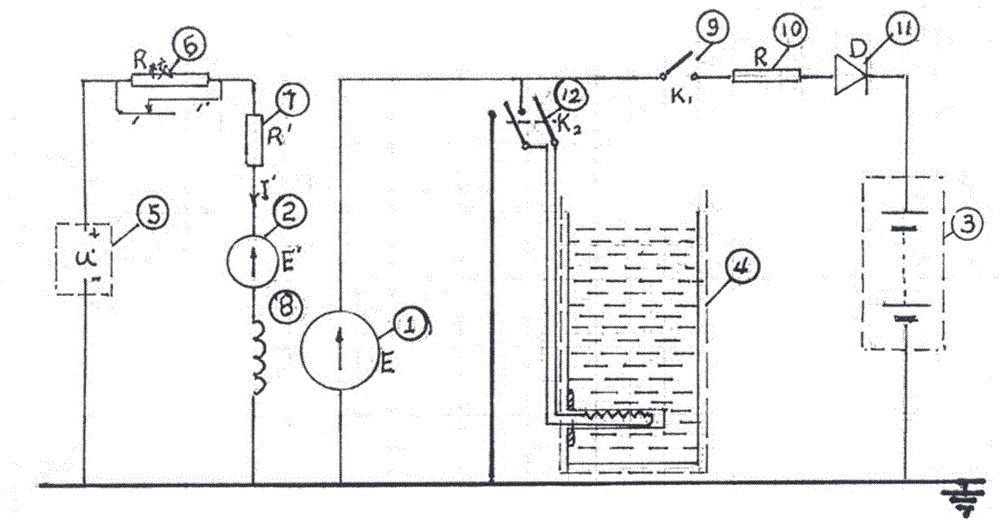

[0029] Embodiment: a kind of electronic stopping device of this embodiment, such as figure 1 As shown, it is mainly composed of: main generator 1, compensation machine 2, energy storage battery pack 3, hot water storage tank 4 and other parts. The main generator is a separately excited DC generator, its function is to convert the remaining kinetic energy of the car into electrical energy, and store the electrical energy in the battery pack by charging the battery pack. The excitation circuit of the main generator consists of excitation power supply u′(5), correction resistor R 校 (6) Consists of current limiting resistor R'7, compensation machine and excitation winding 8 of the main generator, wherein the compensation machine is opposite in polarity to the excitation power supply u'. The output circuit of the main generator is composed of two branch circuits connected in parallel, one branch is switch K1(9), current limiting resistor R(10), isolation diode D(11) and energy sto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com