Large-capacity dry-type high-frequency high- voltage reactor

A high-voltage, large-capacity technology, applied in transformer/reactor installation/support/suspension, transformer/inductor cooling, transformer/inductor magnetic core, etc., can solve the problems of long-term operation reliability, small transmission capacity, Poor waveform quality and other problems, to achieve the effect of ensuring the high-frequency insulation level, saving material costs, and reducing reactive power loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

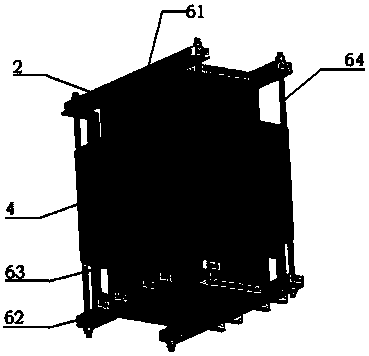

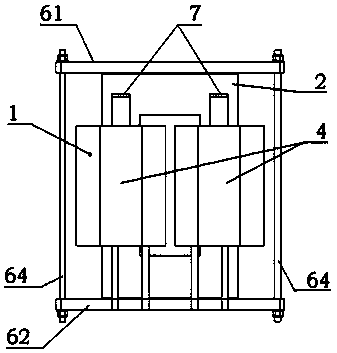

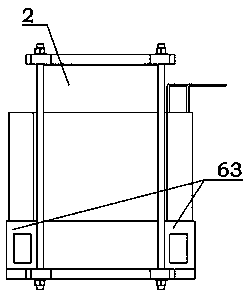

[0072] as attached Figure 1-13 As shown, the large-capacity dry-type high-frequency high-voltage reactor 1 of the present invention includes a UF-type magnetic core 2, a square frame 3, a coil 4, a fixed support device 6, and a copper bar or copper wire 7 for the coil 4. The UF The magnetic core is made up of two U-shaped magnetic parts 21 with opposite openings, several magnetic strips 24 and insulating backing plates 25. Each U-shaped magnetic part 21 includes a bottom yoke 22 and side posts 23 on both sides of the bottom yoke. The magnetic strip 24 and the insulating backing plate 25 are pressed and installed between the side posts 23 of the two U-shaped magnetic parts 21, and the insulating backing plate 25 is arranged between the adjacent magnetic strips 24 and between the magnetic strip 24 and the side post. 23, the insulating backing plate 25 forms a gap 26 between adjacent magnetic strips, and a gap 27 between the magnetic strip and the side column; the square skeleto...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com