Normally-off channel modulation device and manufacturing method thereof

A channel modulation and normally-off technology, applied in the field of microelectronics, can solve the problems of low device manufacturing yield, increase device parasitic capacitance, attenuate device frequency characteristics, etc., achieve simple manufacturing process, good output characteristics, and improve manufactured products rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

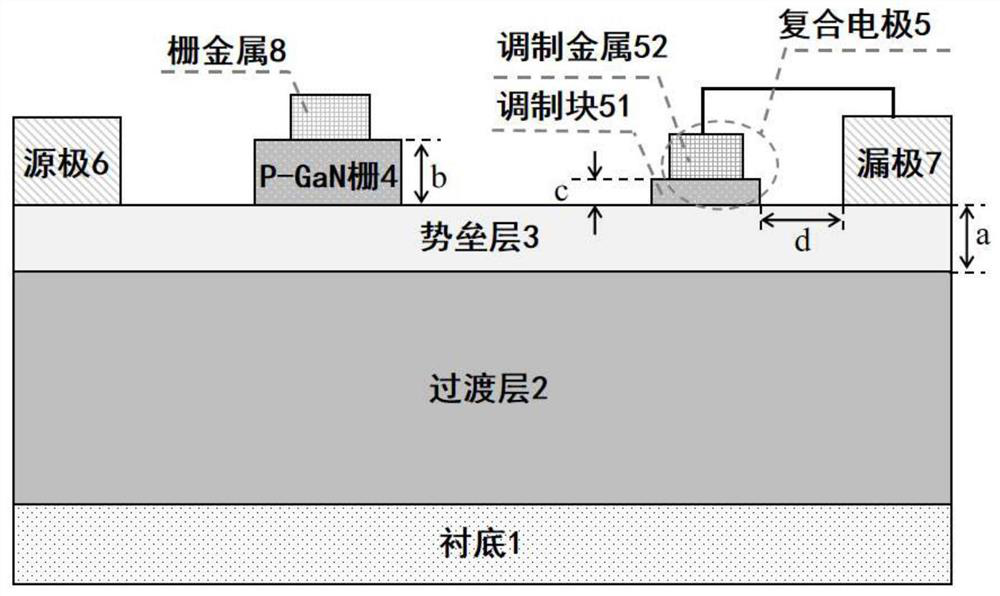

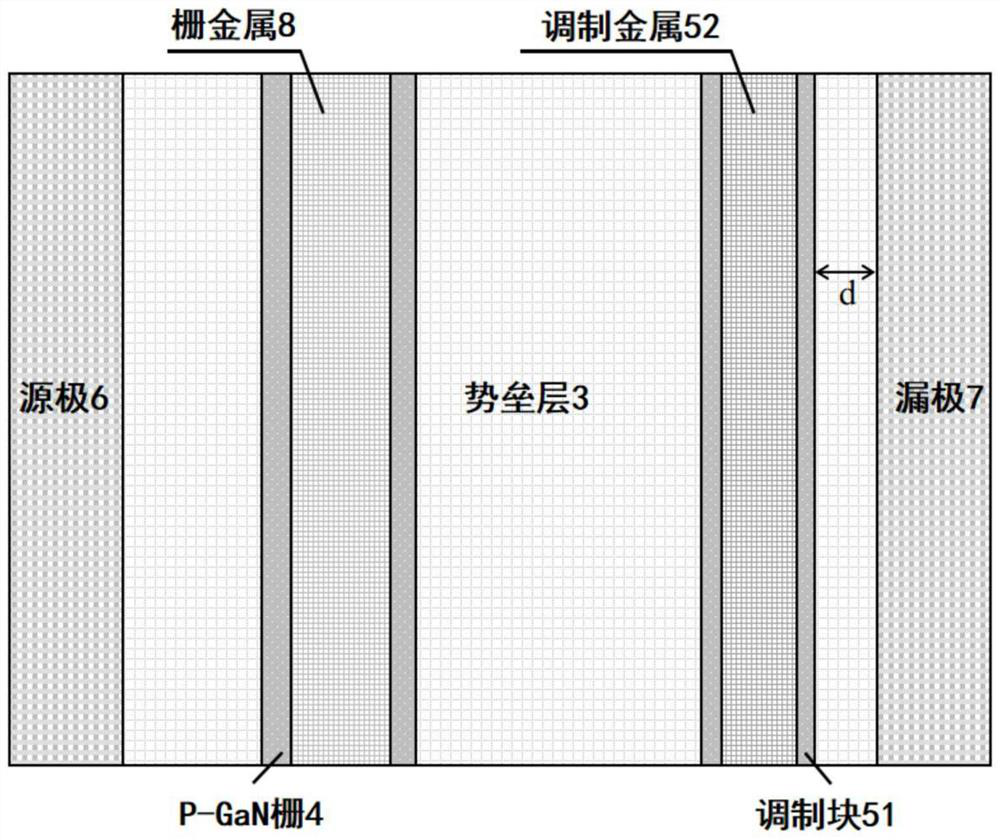

[0057] Example 1: Making the barrier layer 3 thickness in the sapphire substrate is 1 nm, the modulation block 51 doped concentration is 5 × 10 15 cm -3 The thickness is 1 nm, the horizontal distance D = 0 μm of the right end and the left end of the drain 7 is D = 0 μm.

[0058] Step 1. Upper excess GaN material production transition layer 2 in sapphire substrate 1, such as Figure 4 a.

[0059] 1A) GaN material using metal organic chemical vapor deposition techniques at the sapphire substrate 1 is 30 nm, the process conditions are: the temperature is 500 ° C, the pressure is 46 torr, the hydrogen flow is 4300 sccm, the ammonia gas flow is 4300 sccm, gallium The source flow is 21μmol / min;

[0060] 1B) The use of metal organic chemical vapor deposition techniques at GaN material having a thickness of 0.47 μm in GaN material, forming an undoped transition layer 2, wherein the process conditions are: temperature is 960 ° C, the pressure is 45 torr, and the hydrogen flow is 4400 sccm...

Embodiment 2

[0081] Example 2: Making the barrier layer 3 thickness at the silicon substrate is 25 nm, the modulation block 51 doped concentration is 1 × 10 22 cm -3 The thickness is 5 nm, the horizontal distance between the right end of the modulation block 51 and the left end of the drain 7, D = 2 μm.

[0082] Step 1. On the silicon substrate 1, the upper epitaxial Aln and GaN material make transition layer 2, such as Figure 4 a.

[0083] 1.1) Use metal organic chemical vapor deposition techniques at temperatures of 820 ° C, the pressure is 42 torr, the hydrogen flow is 4300 sccm, the ammonia gas flow is 4300 sccm, and the aluminum source is from 21 μmol / min, on the silicon substrate 1. ALN material having a thickness of 300 nm;

[0084] 1.2) Use metal organic chemical gas phase deposition techniques at temperatures of 970 ° C, the pressure is 44 torr, the hydrogen flow is 4400 sccm, the ammonia gas flow is 4400 sccm, and the gallium source flow is 110 μmol / min, and the ALN material is e...

Embodiment 3

[0098] Example Three: a silicon carbide substrate formed on the barrier layer 3 having a thickness of 20nm, the modulation block 51 doping concentration of 6 × 10 18 cm -3 And a thickness of 2.3 nm, and the horizontal distance between a right end of the left end of the drain modulation block 7 to 51 d = channel normally-off modulation device of 3μm.

[0099] Step A. bottom-up on the silicon carbide substrate 1 and the GaN epitaxial material AlN buffer layer 2, such as Figure 4 a.

[0100] A1) setting a temperature of 1050 ℃, pressure of 46Torr, a hydrogen flow rate of 4600sccm, ammonia flow rate of 4600sccm, the aluminum source flow was 6μmol / min, using a metal organic chemical vapor deposition technique in a thickness of epitaxial silicon carbide on the substrate is 90nm the AlN material;

[0101] A2) setting a temperature of 1050 ℃, pressure of 46Torr, a hydrogen flow rate of 4600sccm, ammonia flow rate of 4600sccm, flow rate of the gallium source 100μmol / min, using a metal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com