Oat processing process as well as optimization method and oat processing product thereof

An optimization method and technology of processing technology, applied in food mechanical processing, food science and other directions, can solve the problems of low comprehensive utilization of oats and few varieties of oat products, and achieve the effect of enriching oat-related processing products and improving comprehensive utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

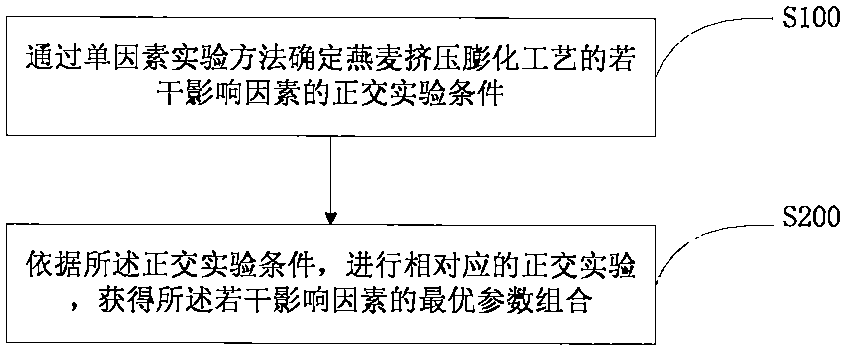

Method used

Image

Examples

Embodiment 1

[0062] Single factor conditional experiment:

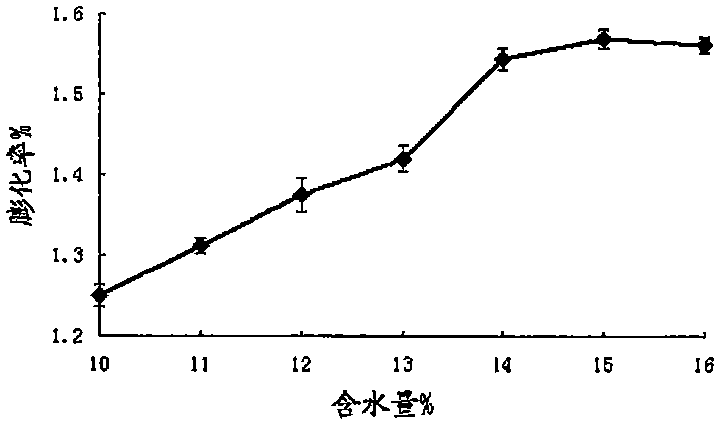

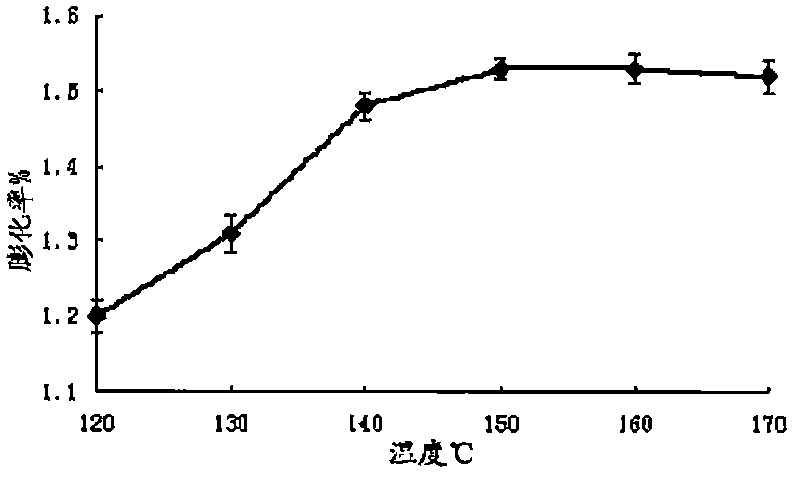

[0063] like Figure 2-4 as shown, figure 2 It is a broken line graph of the influence of material moisture content on the expansion rate during extrusion and expansion, image 3 It is a line graph of the influence of temperature on the expansion rate during extrusion expansion, Figure 4 It is a line graph of the influence of screw speed on the expansion rate during extrusion.

[0064] It can be seen from the line graph that when the water content reaches 15%, the temperature reaches 150°C, and the screw speed reaches 250r / min, the influence on the expansion rate has reached the maximum, which provides a basis for the setting of subsequent orthogonal experimental conditions.

Embodiment 2

[0066] Orthogonal experiment:

[0067] Table 1 is the setting table of orthogonal experimental factors:

[0068]

[0069] Table I

[0070] Table 2 is the orthogonal experiment table:

[0071]

[0072] Table II

[0073] Table 3 is the variance analysis table:

[0074]

[0075] From the results of the above orthogonal experiments, it can be seen that the main factor affecting the expansion rate is the water content of the material, and the order of its influence is water content (A)>temperature (D)>screw speed (C)>feeding speed (B). The optimal solution is A2B1C3D3, that is, the moisture content of the material is 15%, the feeding speed is 250r / min, the screw speed is 300r / min, and the temperature is 150°C.

[0076] The above-mentioned optimal experimental conditions were used for the verification experiment, and the oat dietary fiber extruded and expanded effect was the best, the soluble dietary fiber reached 30.65%, which was 27.25% higher than that of the control...

Embodiment 3

[0078] Comparative experiment of microwave puffing treatment, extrusion puffing treatment and no treatment control oat dietary fiber samples.

[0079] like Figure 5-9 shown, where Figure 5 It is a histogram of the dietary fiber content of the above three processing methods; Image 6 It is the histogram of the oil holding power of the above three treatment methods; Figure 7 It is the histogram of the water holding capacity of the above three treatment methods; Figure 8 is the histogram of the expansion force of the above three processing methods; Figure 9 It is a histogram of the cation exchange capacity of the above three treatment methods.

[0080] Depend on Figure 5 It can be seen that after the above-mentioned different methods of treatment, the soluble dietary fiber in oats increased by 18.74% and 27.25% respectively compared with the control, and the content of soluble dietary fiber in the extrusion-expansion treatment was 3.97% higher than that in the microwav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com