A medium-speed coal pulverizer with ash reduction and desulfurization device

A coal mill and ash reduction technology, which is applied in the field of medium-speed coal mills, can solve the problems of affecting the output of the coal mill, increasing the pressure difference of the coal mill, and increasing the power consumption of the whole plant, so as to reduce high-temperature corrosion and slagging. Tendency, reduction of sulfur emissions, and the effect of reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

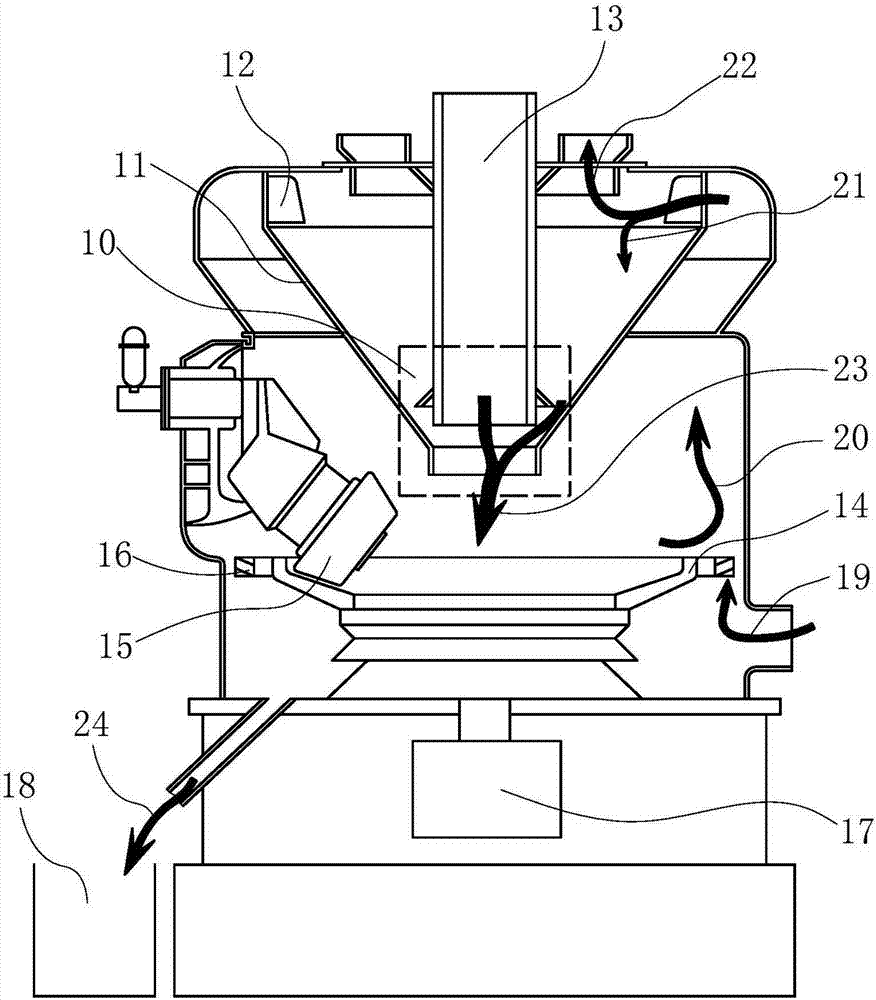

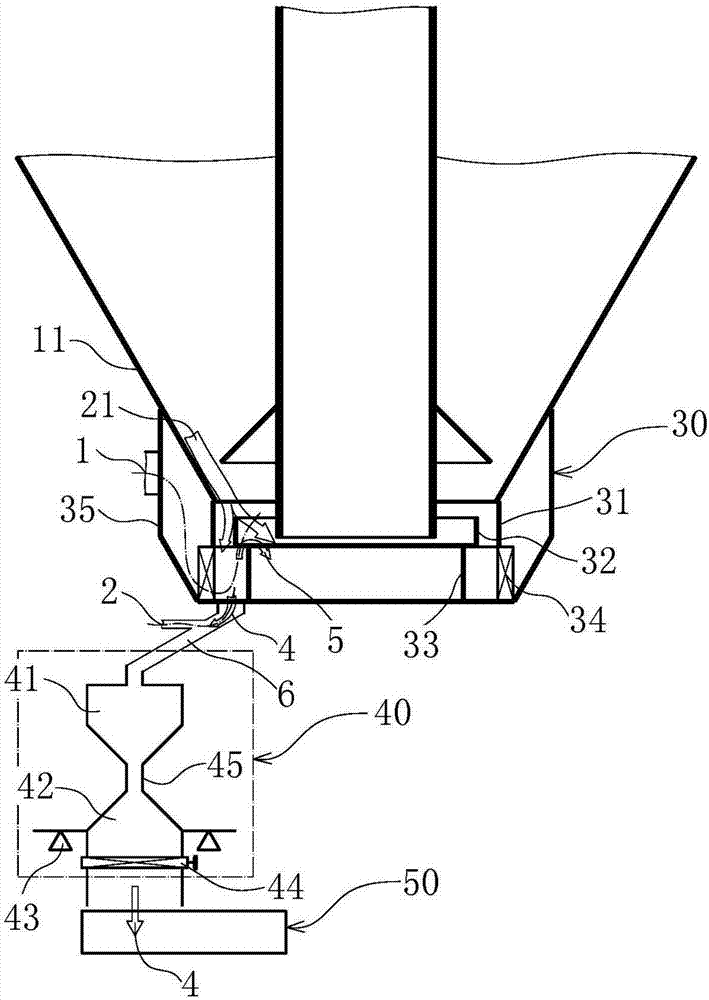

[0051] A medium-speed coal mill with an ash reduction and desulfurization device, including a coal drop pipe, a conical shell, a coarse powder separator baffle, a grinding ring, and an ash reduction and desulfurization device. The baffle is set on the top of the cone shell, and the grinding ring is set under the cone shell. The ash reduction and desulfurization device includes an impurity separation module, an impurity discharge pipe, an impurity sensing module, an impurity conveying system and a system control module. The impurity separation module is set at a medium speed The bottom of the inner cone shell of the coal mill, and the impurity sensing module is located outside the medium-speed coal mill;

[0052] The impurity separation module includes the first circular ring, the second circular ring, the third circular ring, the impurity separation baffle and the impurity separation module shell arranged between the cone shell and the grinding ring, the first circular ring, th...

Embodiment 2

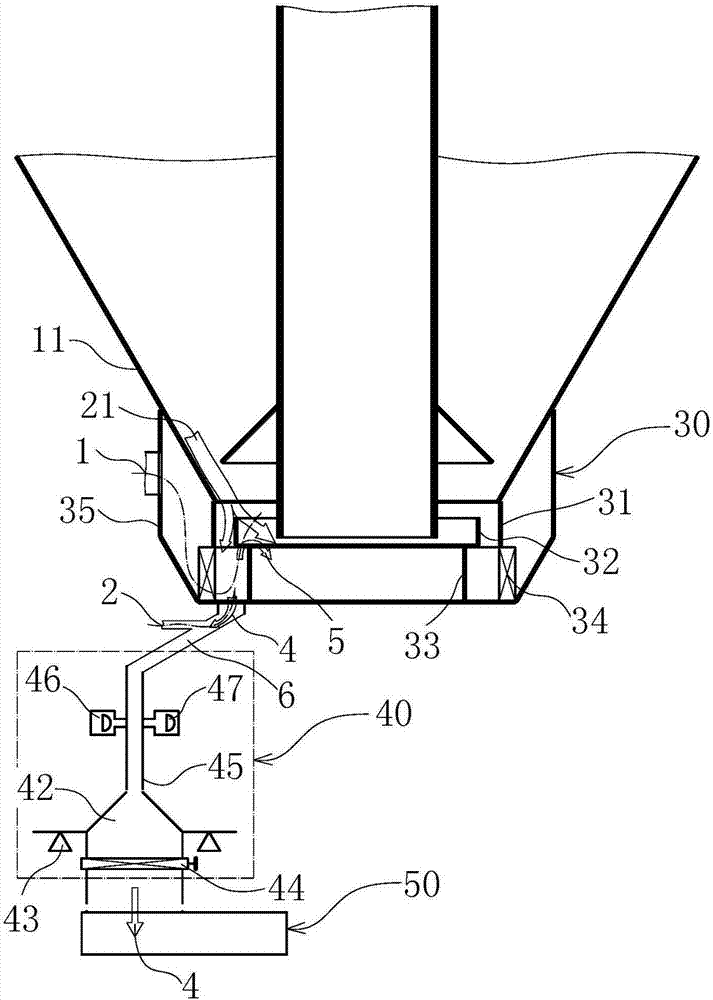

[0060] It is basically the same as Embodiment 1, except that the impurity sensing module does not include a buffer bucket but includes an optical path detector on the impurity discharge pipe, and the optical path detector includes a transmitting end and a receiving end.

Embodiment 3

[0062] It is basically the same as Example 1, except that: the bottom of the buffer bucket and the top of the weighing bucket are conical structures, and the cone angles are both 30°; the tangential angle between the impurity separation baffle and the circumference is 15° .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com