Spiral coil and plunger combined type injection molding device

An injection molding device and combined technology, which is applied in the field of injection molding of polymer materials, can solve the problems of screw plasticization, crushing and extrusion capabilities, high complexity of the overall system, and high cost, and achieve the inherent quality and Improved appearance quality, optimized processing process, and strong plasticizing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

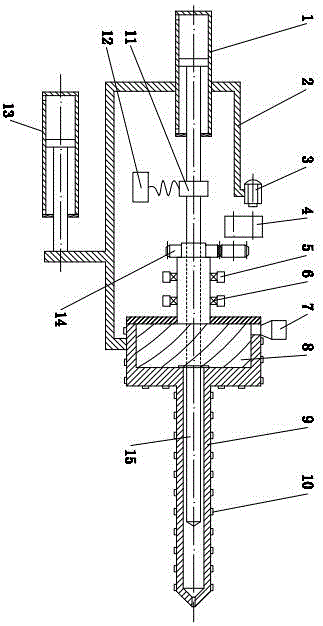

[0036] Such as Figure 1 to Figure 4 As shown, it is a combined screw and plunger injection molding device, including injection cylinder 1, injection seat frame 2, motor 3, transmission mechanism 4, seat 5, centripetal thrust bearing 6, hopper 7, barrel 9. Electric heater 10, mobile cylinder 13, gear 14 and plunger 15;

[0037] The injection cylinder 1, the motor 3 and the transmission mechanism 4 are all installed on the injection seat frame 2, and the push rod of the mobile oil cylinder 13 is connected with the injection seat frame 2, so that the push rod of the mobile oil cylinder 13 can push the injection seat frame 2 to move ;

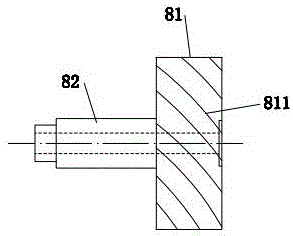

[0038] Described plasticizing screw disk 8 comprises rotating disk 81 and cylinder 82, and described cylinder 82 is positioned at the left end of rotating disk 81, and is provided with more than three outer circumferential screw grooves 811 on the cylindrical surface of described rotating disk 81, on the rotating disk 81 The right end face is pr...

Embodiment 2

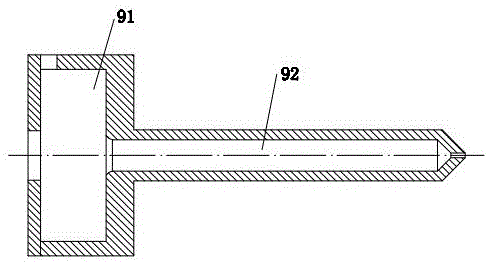

[0044] Such as Figure 5 As shown, it is a combination screw and plunger injection molding device, its structure and working principle are basically the same as the first embodiment, the difference is that the injection cylinder 92 is a stepped hole, and the stepped hole The part with a large middle diameter is connected to the plasticizing chamber 91, and the part with a small diameter in the stepped hole is connected with the injection hole. Good melt material can enter the right section of the injection cylinder 92 through this gap under pressure, and the outer circular surface of the right part of the plunger 15 is in a sliding fit with the part of the stepped hole of the injection cylinder 92 with a small diameter, but the melt material cannot be fitted from it. Pass through the gap, but the volume of the small hole in the stepped hole must be greater than the minimum injection volume set by the injection machine. The working principle is basically the same as that of Em...

Embodiment 3

[0046] Such as Figure 6 As shown, it is a combined screw and plunger injection molding device. Its structure and working principle are basically the same as those in Embodiment 1. Reverse head 16 ), the one-way valve 16 (or non-return head 16 ) is located in the injection cylinder 92 , and the one-way valve 16 (or non-return head 16 ) can move axially in the injection cylinder 92 . The non-return head is a device to prevent the molten material from flowing back during injection. Its working principle is very similar to that of a one-way valve. Since this technology is relatively mature and is not the focus of this patent, the structure of the non-return head will not be discussed here. The principle is described.

[0047] When working, the motor 3 drives the plasticizing screw disk 8 to rotate through the transmission mechanism 4 and the gear 14. The outer circumferential thread groove 811 and the end surface spiral groove 812 on the plasticizing screw disk 8 are used as mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com