Anti-lock braking device of steering drive axle hub brake and design method thereof

An anti-lock braking, braking technology, applied in the direction of brakes, ABS control systems, etc., to achieve the effect of widening the width and avoiding interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Best practice:

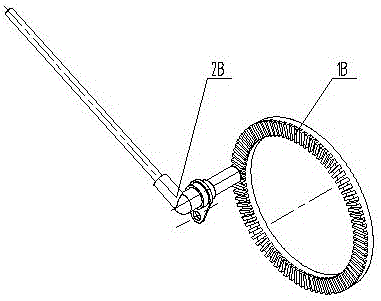

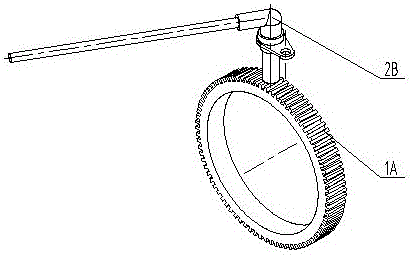

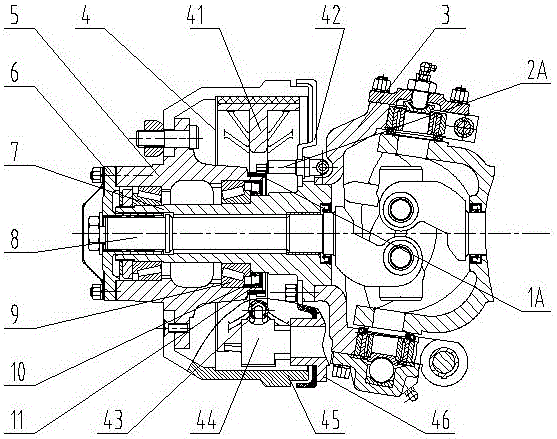

[0033] Refer to attached image 3 , the anti-lock braking device of the steering drive axle hub brake brake, including cylindrical tooth rotor 1A, flat head wheel speed sensor 2A, steering knuckle shell 3, brake assembly 4, hub 5, outer half shaft flange 6, hub shaft Pipe 7, outer half shaft 8, taper bearing 9, spacer sleeve 10, oil seal 11, etc. Brake assembly 4 is made up of brake shoe and friction plate assembly 41, brake base plate 42, return spring 43, camshaft 44, brake hub 45, camshaft support 46, adjustment arm, push rod and air chamber etc.

[0034] The design method of the anti-lock braking device of the above-mentioned steering drive axle hub brake is as follows:

[0035] First, the radial space required for the spur tooth rotor 1A is set. The inner hole of the cylindrical tooth rotor 1A and the outer diameter of the hub 5 adopt an interference fit, and are press-fitted on the hub 5 . This requires the oil seal 11 and the spacer 10 with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com