Solid-liquid separation device and application thereof

A technology of solid-liquid separation and cavity, which is applied in the direction of centrifugal separation water/sewage treatment, water/sewage treatment, flocculation/sedimentation water/sewage treatment, etc. It can solve the complex structure of sedimentation tanks, long construction period, and difficult equipment installation, etc. problems, achieve the effect of improving the solid-liquid separation speed and separation effect, low maintenance cost, and low probability of failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

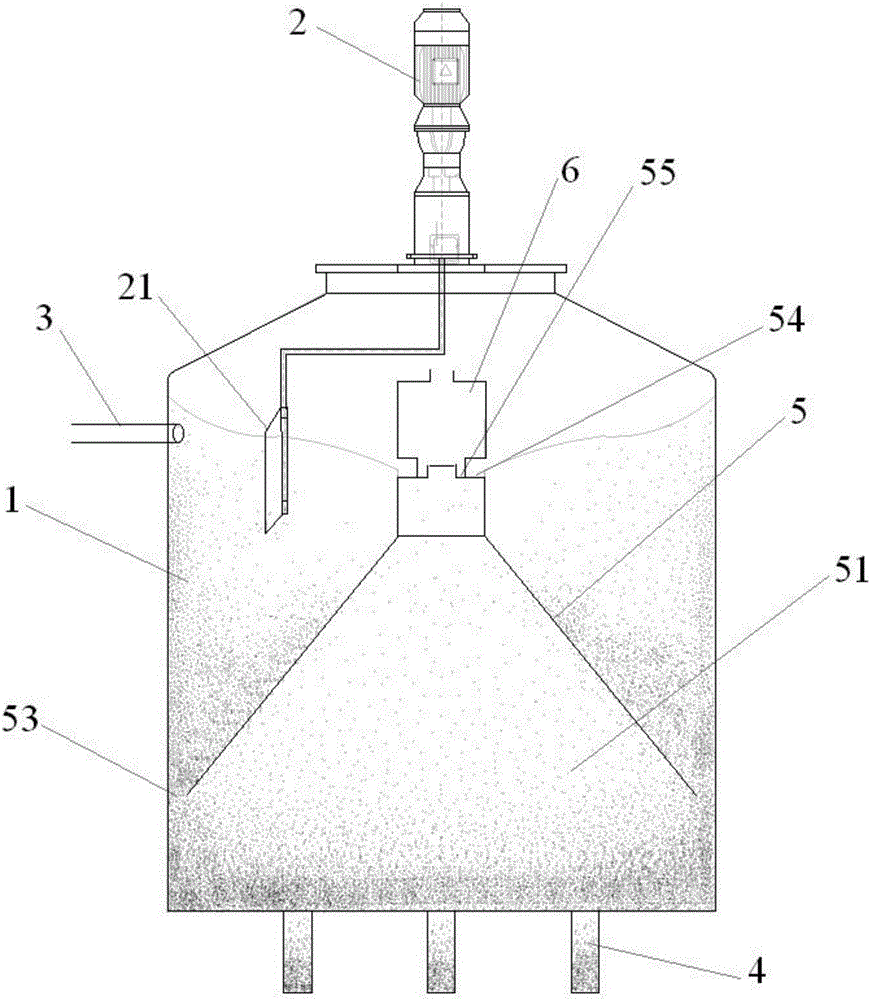

[0075] The solid-liquid separation device of this example is as Figure 12 As shown, its main body is a cylindrical barrel container, and the cylindrical barrel container has a cylindrical cavity 1, and the top of the cylindrical cavity 1 is equipped with a stirring flowmaker 2, and the turbulent slurry 21 of the stirring flowmaker extends into the The interior of the cylindrical cavity 1 is at about 1 / 3 depth; the upper side wall of the cylindrical cavity is provided with a sewage inlet 3, and the bottom is provided with a mud discharge port 4; The plate 5 encloses a relatively closed conical cavity 51 inside the cylindrical cavity, and the partition plate is arranged so that the bottom of the conical cavity is located at about 2 / 3 of the depth of the cylindrical cavity, and the top of the conical cavity is located at the depth of the cylindrical cavity. About 1 / 3 of the depth of the shaped cavity; the dividing plate at the bottom of the conical cavity, that is, the dividing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com