Built-in vertical flow precipitation type anaerobic reactor

An anaerobic reactor and vertical flow sedimentation technology, which is applied in the field of built-in vertical flow sedimentation anaerobic reactor, can solve the problems of incomplete separation of biogas, sewage and sludge, high concentration, increased load, etc., and achieve sludge reduction Effects of acclimatization time, increasing methanogenesis activity, and increasing ascending velocity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The above solution will be further described below in conjunction with specific embodiments. It should be understood that these examples are used to illustrate the present invention and not to limit the scope of the present invention. The implementation conditions used in the examples can be further adjusted according to the conditions of specific manufacturers, and the implementation conditions not indicated are usually the conditions in routine experiments.

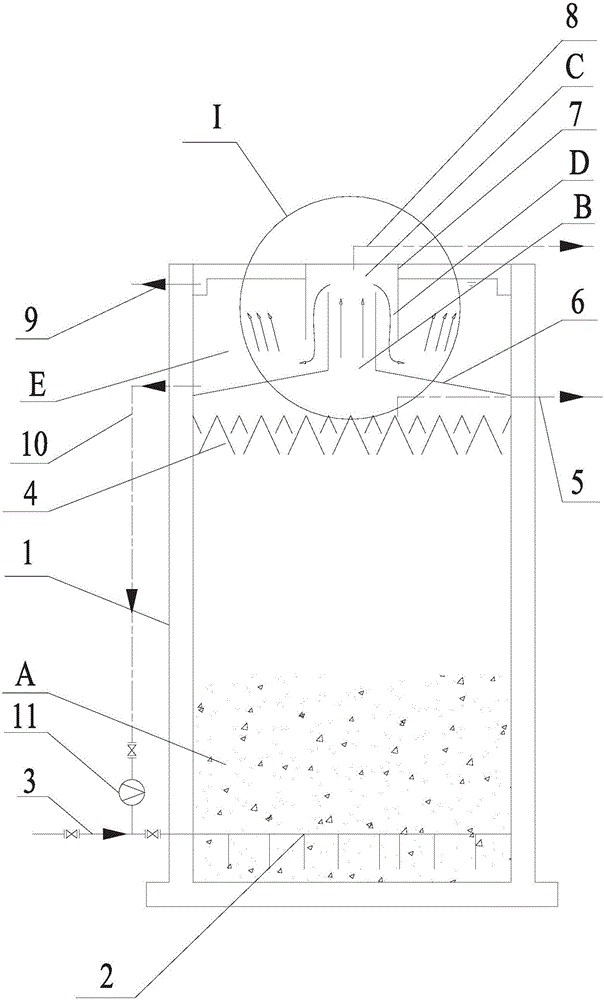

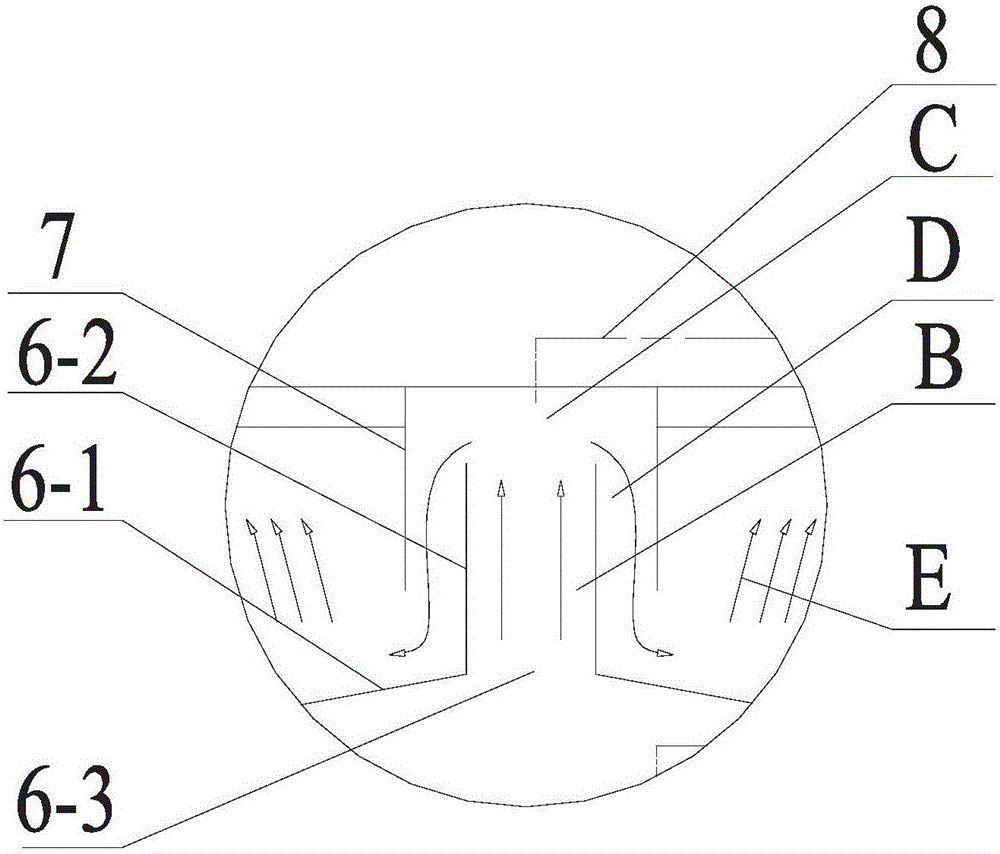

[0037] see Figure 1-2 , is a structural schematic diagram of an embodiment of the present invention, providing a built-in vertical flow sedimentation anaerobic reactor, including an anaerobic reactor body 1, a water distributor 2 is provided at the bottom of the anaerobic reactor body 1, and a water distributor 2 Connected to the water inlet pipe 3, the lower part of the anaerobic reactor body 1 is the sludge expansion reaction zone A, and a three-phase separator 4 is arranged above the sludge expansion reactio...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap